Mixing melting device for preparing modified emulsified asphalt, and use method thereof

A technology for emulsified asphalt and blending, applied in chemical instruments and methods, mixing methods, emulsification, etc., can solve problems such as poor blending effect, and achieve the effects of compact structure, high product performance and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

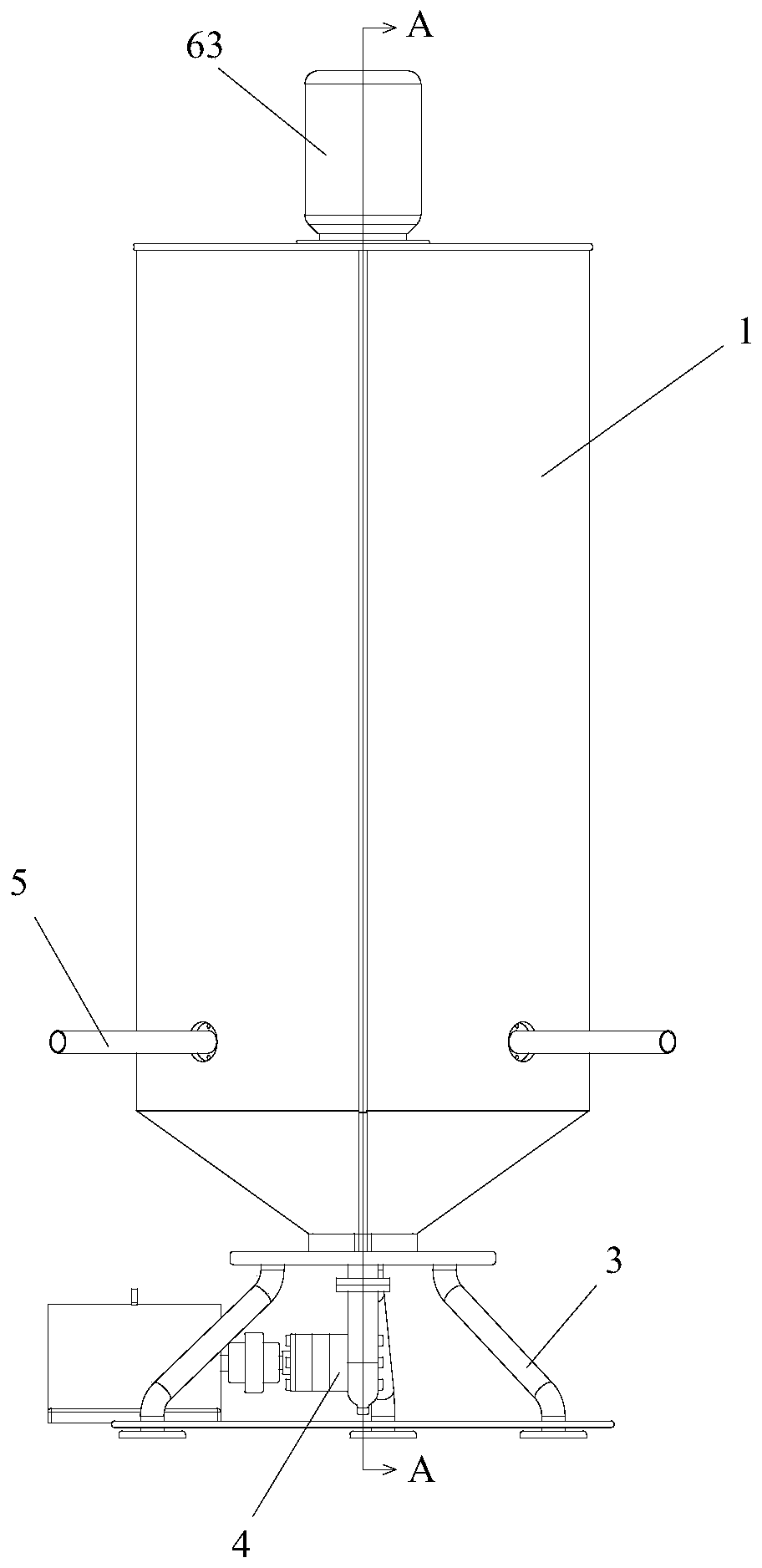

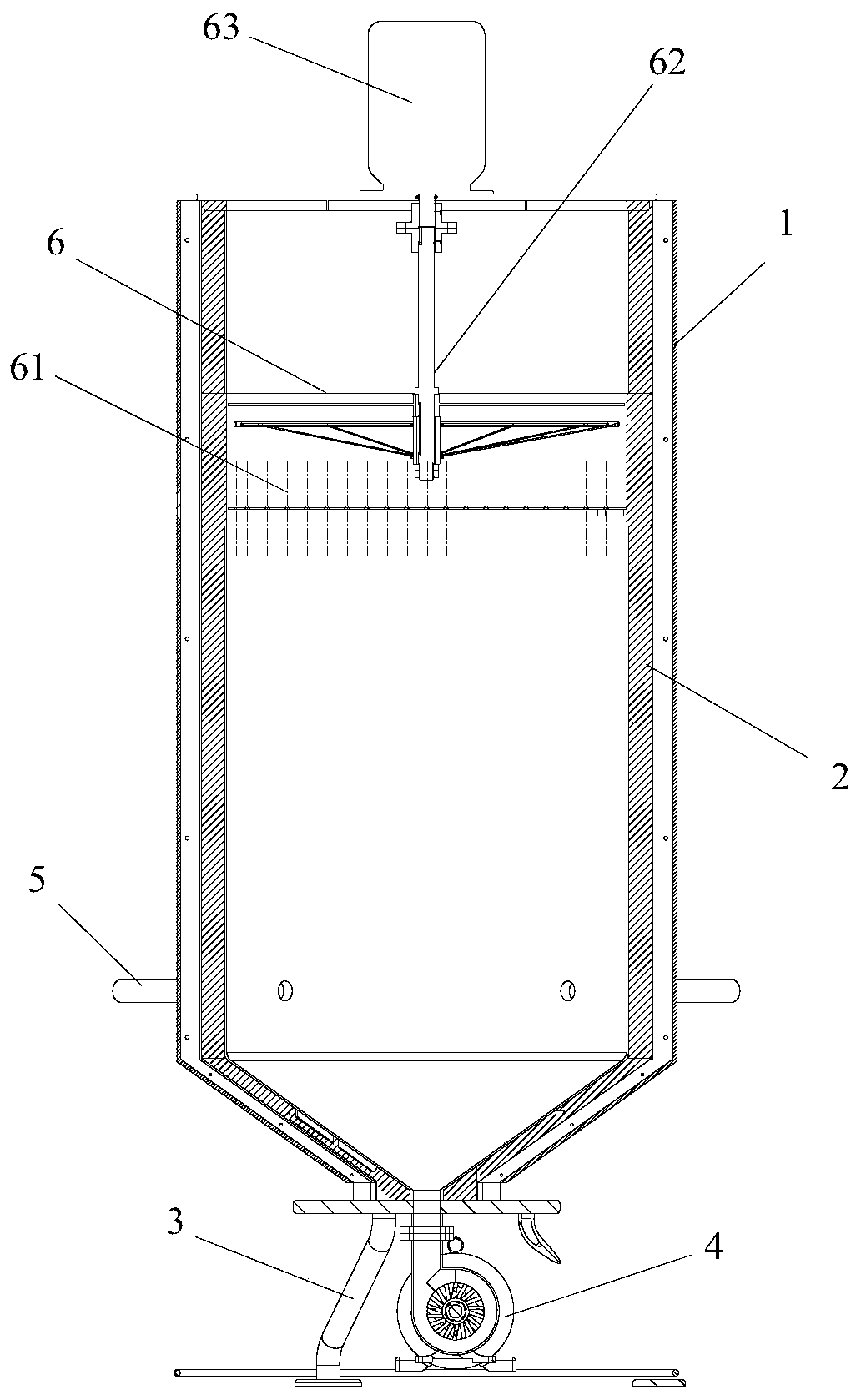

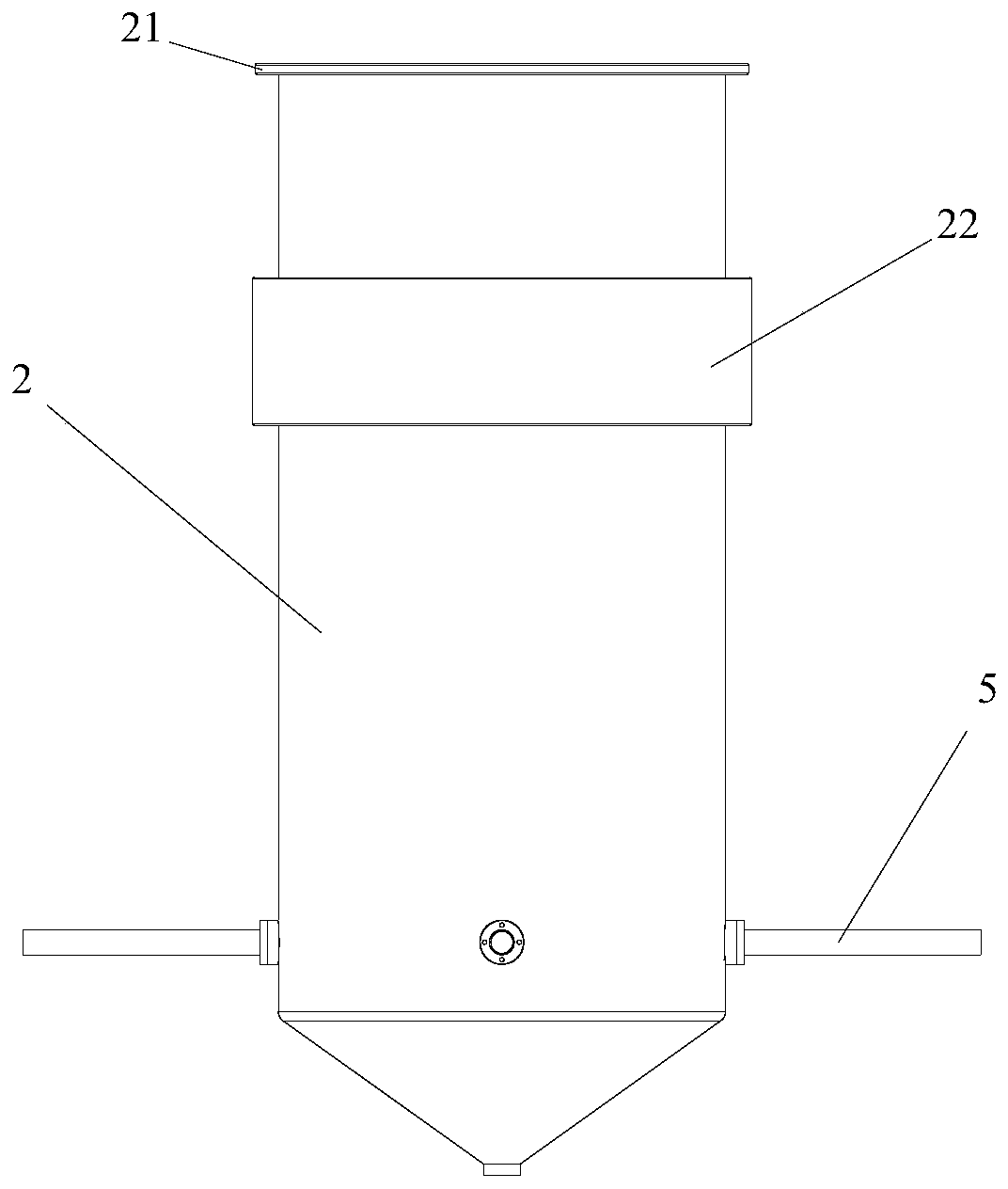

[0027] Please also refer to Figure 1 to Figure 5 , as shown in the figure, the mixer for preparing modified emulsified asphalt includes a base 3, an outer cylinder 1 placed on the base 3, an inner cylinder 2 built into the outer cylinder 1, a stirring device 4, and a feed pipe 5 is connected to the inner cylinder 2 through the outer cylinder 1. Feed pipe 5 is a five-channel feed pipe, which is a group of stainless steel temperature control pipes, and is a passage for soap liquid, asphalt, modifier, transition liquid, and filtrate. The stirring device 4 includes a suction swirl volute 41 and a first motor 44 that drives the swirl core 45 inside the swirl volute 41 to work. The first motor 44 acts on the swirl volute 41 through the coupling 43 and the bearing seat 42, wherein the top interface of the swirl volute 41 is connected to the outlet of the lower end of the inner cylinder 2, and the swirl volute 41 has a cage-type swirl core 45. A colloid mill (not shown) is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com