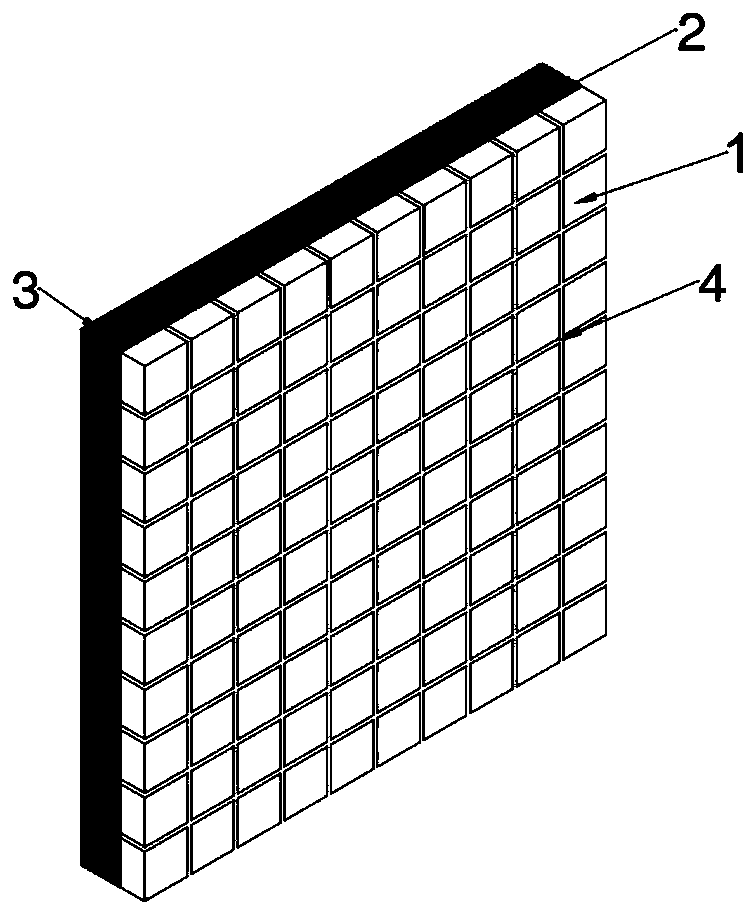

Ultra-light armor and preparation method thereof

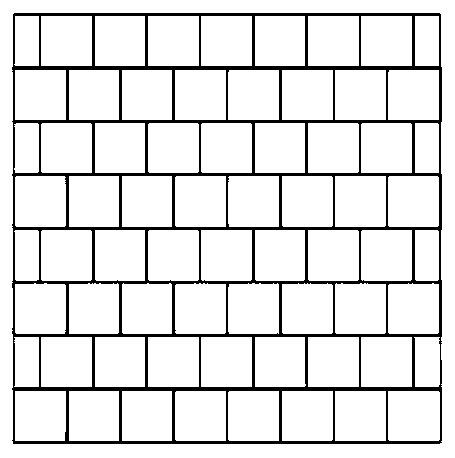

A technology of armor and encapsulation layer, which is applied to the structure of armor, protective equipment, armor plate, etc. It can solve the problems of inability to provide structural support, large impact deformation, insufficient rigidity, etc., and achieve the improvement of excessive damage area and high energy absorption efficiency , The effect of improving the ability to resist multiple bullets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

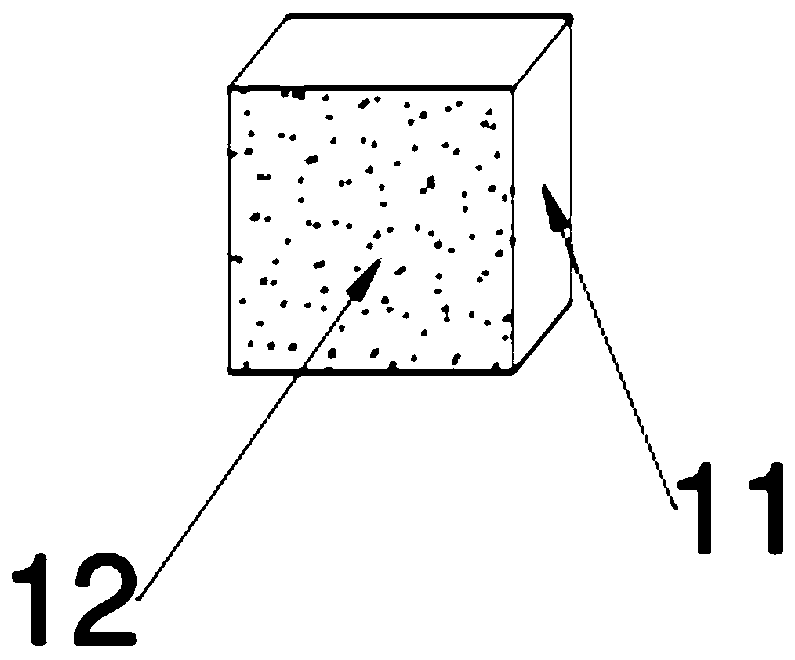

[0111] Choose a square boron carbide ceramic with a side length of 50mm and a thickness of 5mm. Use a 0.2mm thick plain weave aramid cloth to package the ceramic. The packaging steps are:

[0112] Design the shape of the packaging cloth according to the shape of the ceramic. Take the ceramic facing surface as the front or the axial rotation center. The rotating ceramic is expanded laterally based on one of the sides, and then the two ceramics are centered on each expanded side. It is unfolded on both sides to design the shape drawing of the aramid cloth for packaging ceramics, and the cutting drawing of the aramid cloth for packaging is like Figure 5 As shown, 12-1 is the ceramic facing surface and the size is 50mm*50mm, and 11-1 is the side surface to avoid chamfering loss, and the size is 50mm*5.5mm;

[0113] according to Figure 5 The drawing, the cutting edge is parallel to the radial or weft direction of the aramid cloth, and the aramid cloth of the corresponding shape is cut;...

Embodiment 2

[0128] According to the method described in Example 1, the human body protection chest insert is prepared. The difference from Example 1 is that it uses a square boron carbide ceramic with a side length of 7mm, a 2mm thick titanium foam component with a porosity of 20%, and a 10mm thick ultra-high molecular weight. Polyethylene fiber laminate is used as the back sheet.

[0129] According to the method of Example 1, the surface density of the human body protection chest insert prepared in Example 2 of the present invention is 24kg / m 2 , The impact surface density is 35kg / m 2 ; Compared with products of the same level of protection, the areal density is reduced by 25%.

[0130] Use the Type 53 7.62mm armor-piercing incendiary bomb and test it in accordance with the "GA950-2011 V50 Test Method Test of Bulletproof Materials and Products". Its V50> 818m / s, three effective shots, all partially penetrated, and the height of the back protrusion is less than 20mm, which meets the requirement...

Embodiment 3

[0131] Example 3 Against the threat of 54 type 12.7mm*108mm API armor-piercing incendiary bomb

[0132] Choose a regular hexagonal boron carbide ceramic with a length of 83mm on the opposite side and a thickness of 13mm. Use a 0.2mm thick glass fiber cloth to package the ceramic. The package method is:

[0133] Design the shape of the packaging cloth according to the shape of the ceramic. Take the ceramic facing surface as the front or the axial rotation center. The rotating ceramic is expanded laterally based on one of the sides, and then the two ceramics are centered on each expanded side. It is unfolded facing both sides to design the shape drawings of the glass fiber cloth encapsulating ceramics, and the cutting drawings of the glass fiber cloth encapsulating Image 6 As shown, 12-1 is the ceramic facing surface, the size is 48mm*48mm, and 11-1 is the side. To avoid chamfering loss, the side size is 48mm*13.5mm; the side length of the regular hexagon with the opposite side lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com