Improved up-flow anaerobic ammoniation reactor and method for treating high-organic nitrogen printing and dyeing wastewater

A technology for ammonification reactors and printing and dyeing wastewater, which is applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc. It can solve problems such as inconvenient operation, poor control ability, and insufficient mixing degree of mud and water. Achieve the effect of improving CODCr removal rate, improving anaerobic ammoniation efficiency, and improving impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

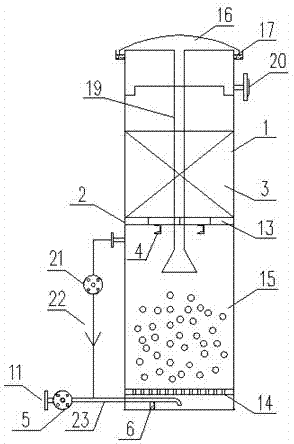

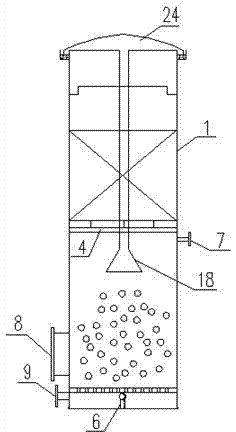

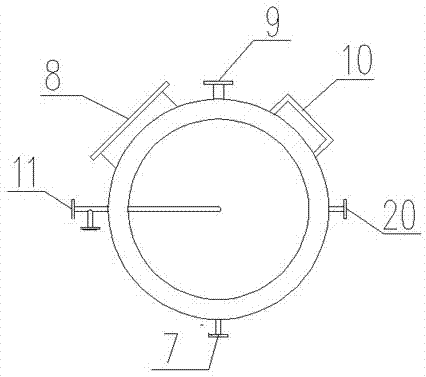

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

[0025] combine Figure 1 to Figure 4 , an improved upflow anaerobic ammoniation reactor for treating high organic nitrogen printing and dyeing wastewater proposed by the present invention, which includes a tower body (1), and the tower body (1) is sequentially provided with three-phase separators from top to bottom (18) gas collection system (16), tower body outlet (20), anaerobic sludge reaction zone (15), water distribution system (14), water inlet pump (5) and connecting tower body (1) up and down Internal circulation system (22); wherein: also includes an anaerobic biofilm reaction zone composed of filler (3), filler lining bracket (2) and anaerobic biofilm formed on the filler (3), the anaerobic biofilm The reaction zone is set between the tower body water outlet (20) and the anaerobic sludge reaction zone (15); th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com