Preparation method for porous boron-doped diamond composite electrode with bimetallic synergistic effect and application of porous boron-doped diamond composite electrode in detection of glucose

A boron-doped diamond and bimetallic synergy technology is applied to the preparation of a porous boron-doped diamond composite electrode with bimetallic synergistic effect and its application field for glucose detection, which can solve the problems of low sensitivity of glucose and achieve strong redox, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

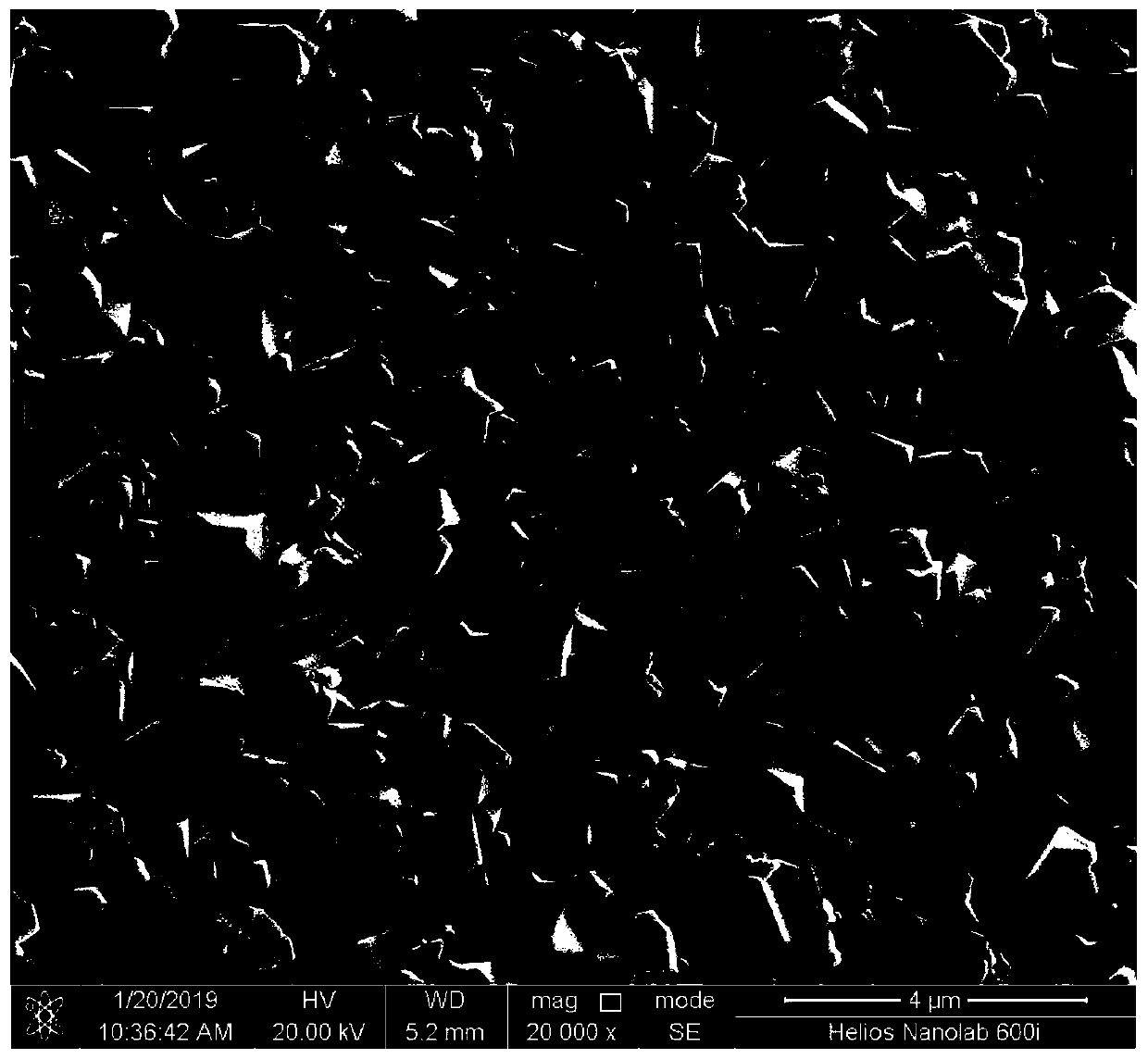

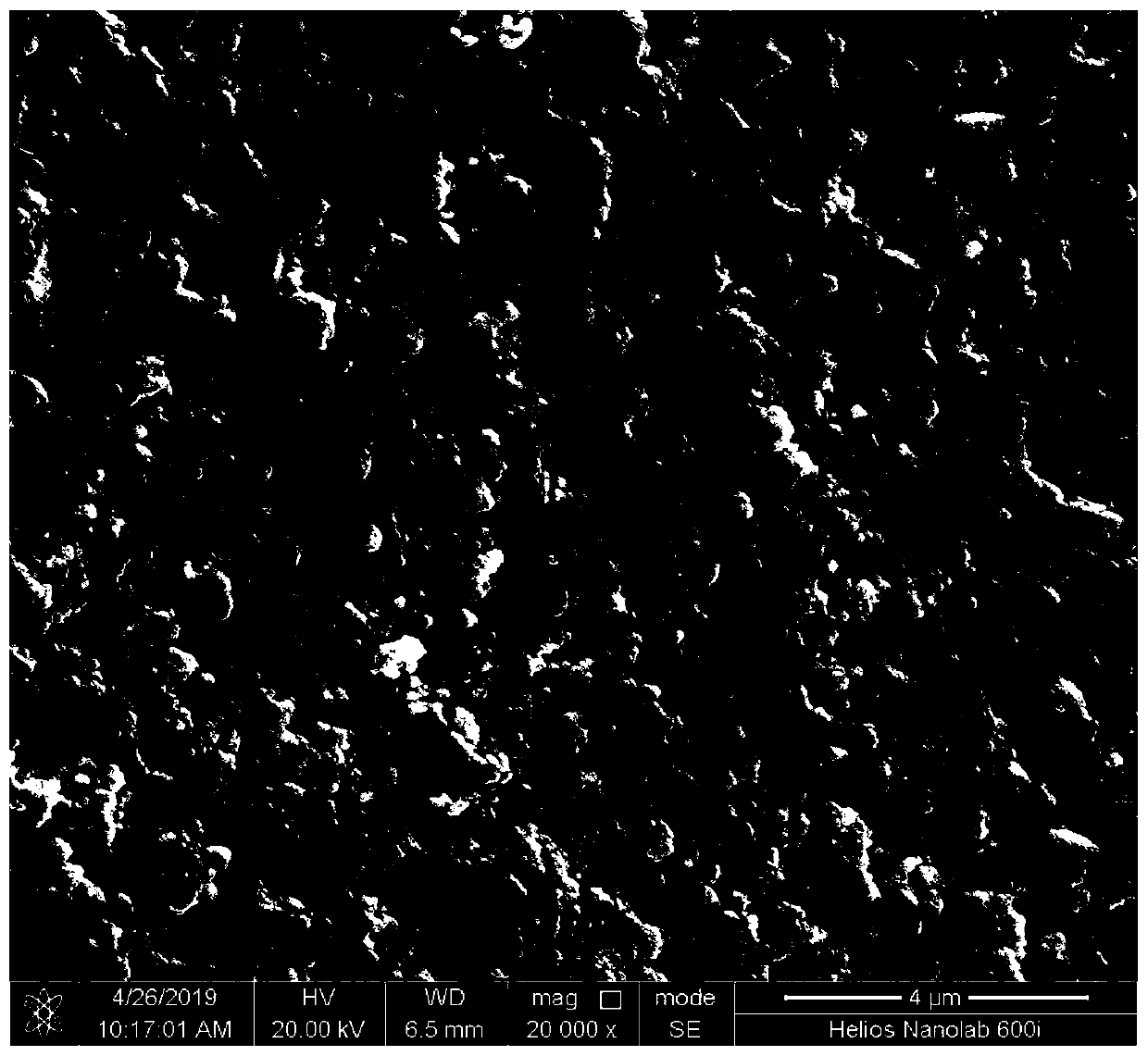

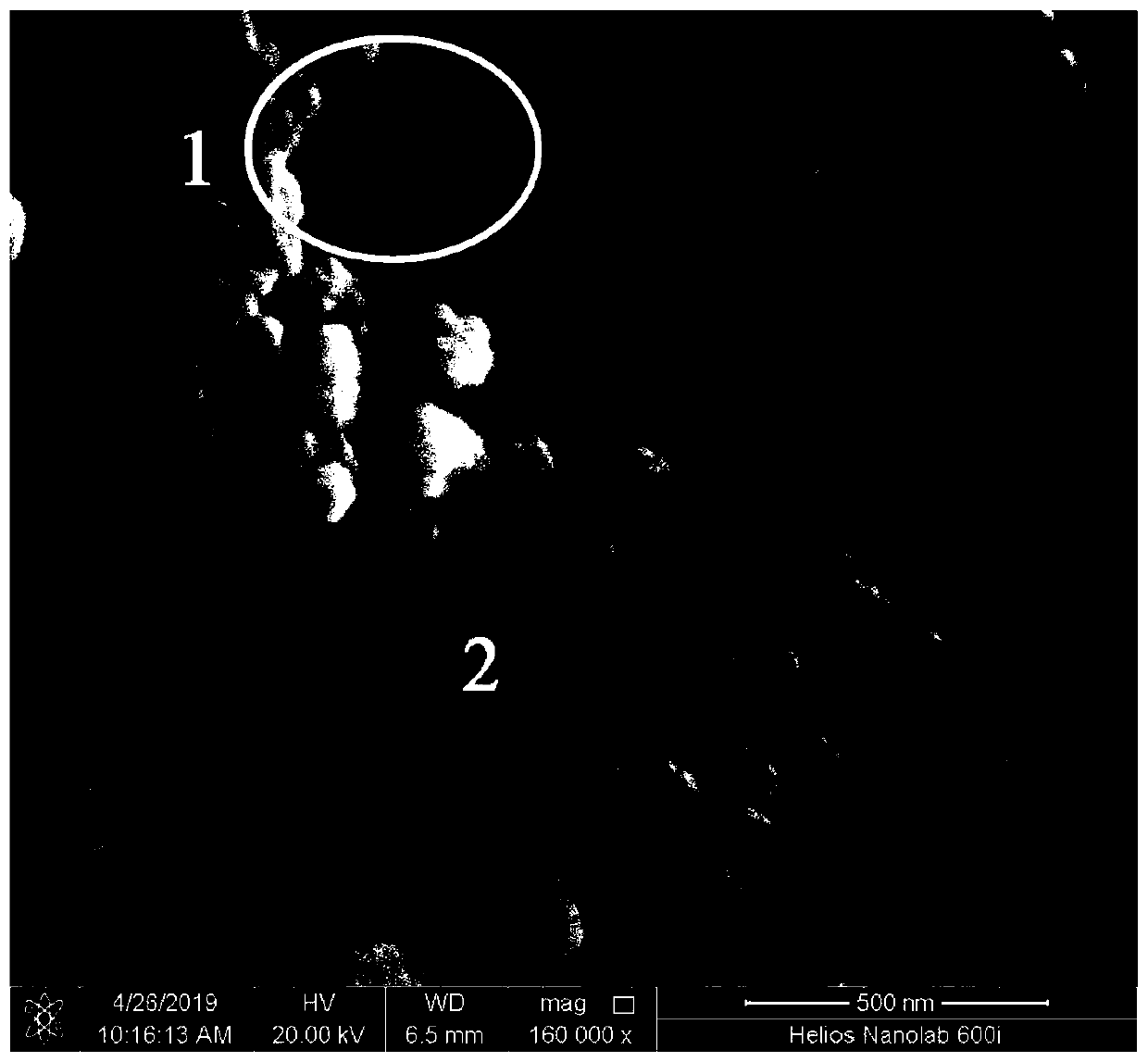

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: present embodiment a kind of preparation method of the porous boron-doped diamond composite electrode with double metal synergistic effect, it is carried out according to the following steps:

[0028] 1. Preparation of boron-doped diamond film:

[0029] Place the silicon wafer in a spin coater, and drop the nano-diamond suspension with a mass percentage of 2% to 15% under the condition of a rotating speed of 500 rpm to 2000 rpm, and spin coat it for 3 to 6 times , and dried to obtain a silicon wafer spin-coated with nano-diamonds, place the silicon wafers and graphite wafers spin-coated with nano-diamonds side by side on the sample stage of a microwave plasma chemical vapor deposition device, feed hydrogen and diborane gas, and The flow rate of hydrogen is 100sccm~500sccm, the flow rate of diborane gas is 1sccm~20sccm, the temperature of silicon wafer spin-coated with nano-diamond is 550℃~1000℃, the temperature of graphite sheet is 650℃~1100℃, t...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the graphite flakes described in step 1 have a purity of 99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the graphite sheet described in step 1 is a square sheet with a side length of 20 mm to 60 mm and a thickness of 2 mm to 5 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com