Device for preparing cerium-based catalyst

A cerium-based catalyst and reaction chamber technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of limited dioxin emission reduction effect and complicated operation , high price and other problems, to achieve excellent redox ability, low price, and the effect of promoting preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

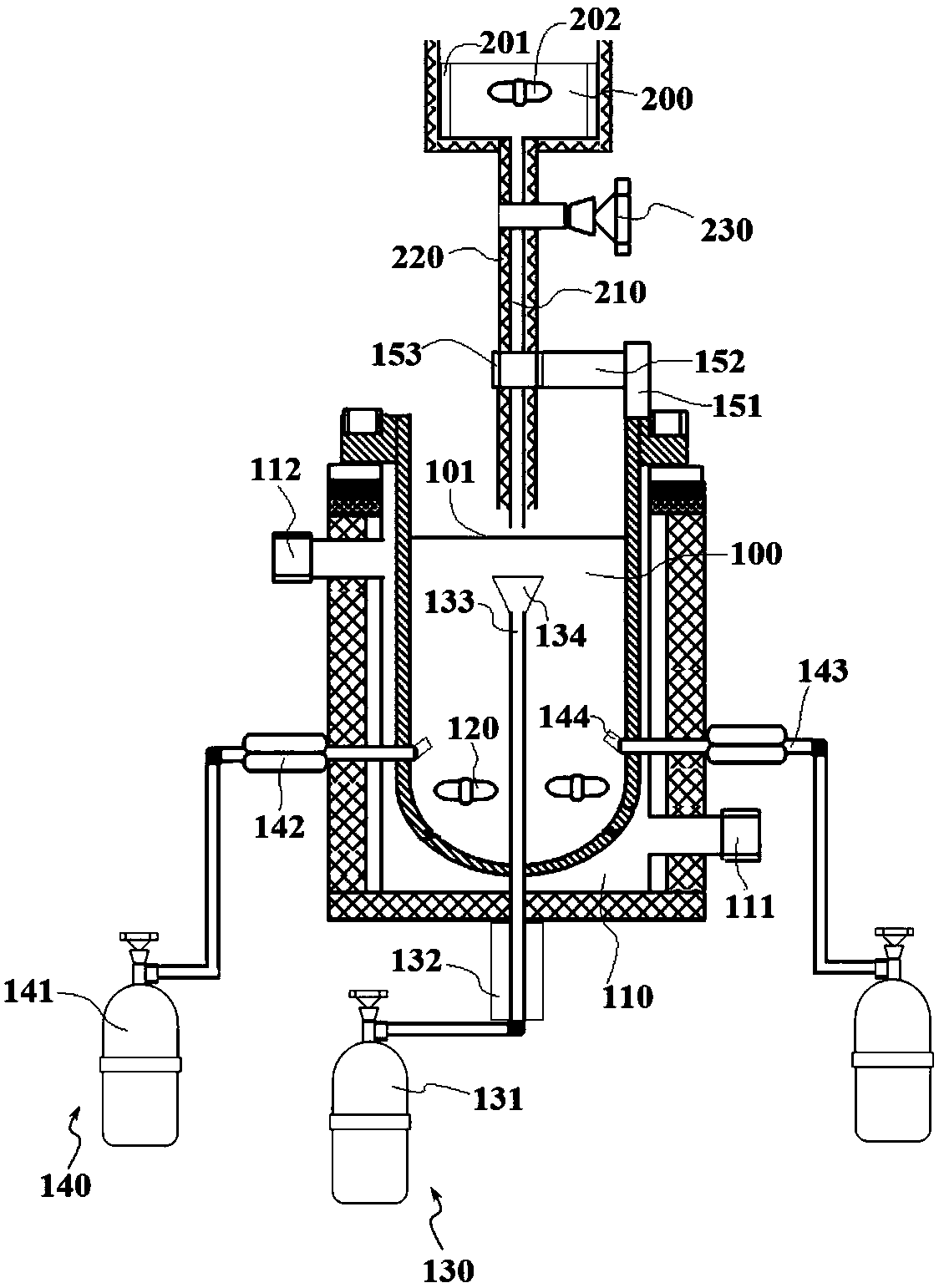

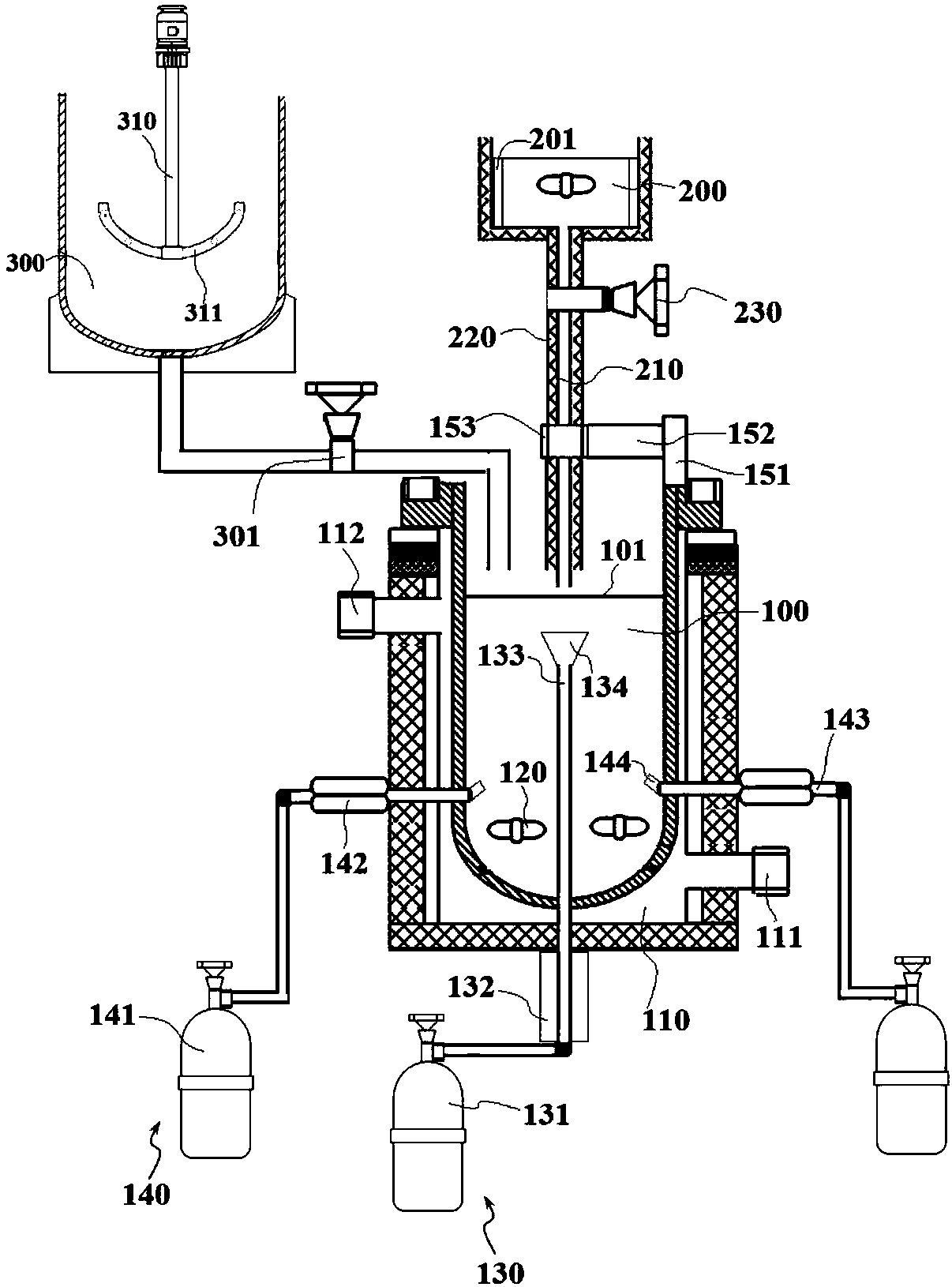

[0043] Such as figure 2 and image 3 As shown, a device for preparing a cerium-based catalyst in this embodiment includes a reaction chamber 100 and an oxalic acid pool 200. The upper part of the reaction chamber 100 is provided with an oxalic acid pool 200, and the oxalic acid pool 200 is provided with an electromagnetic stirring mechanism 201 and The mechanical stirrer 202 ; the electromagnetic stirring mechanism 201 and the mechanical stirrer 202 are used to stir the oxalic acid solution in the oxalic acid pool 200 .

[0044] An oxalic acid dropper 210 is arranged under the oxalic acid pool 200, and a telescopic support arm 152 is provided on the top of the reaction chamber 100. The telescopic support arm 152 is connected to the top of the reaction chamber 100 by rotating the support rod 151. Holding mechanism 153, the holding mechanism 153 is used to hold the oxalic acid dropper 210, the oxalic acid dropper 210 is fixed on the upper part of the reaction chamber 100 by th...

Embodiment 2

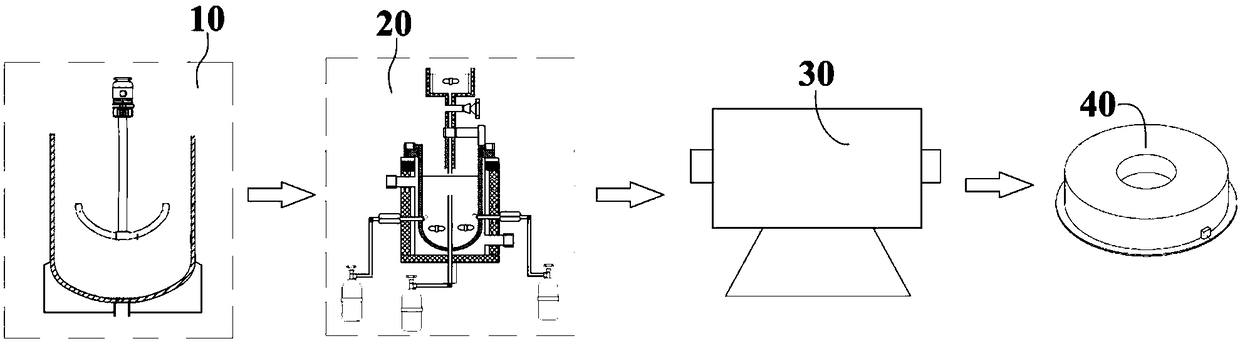

[0052] In this embodiment, the method for producing the catalyst using the above-mentioned cerium-based catalyst production system for synergistically removing dioxins and nitrogen oxides is as follows: add ferrous sulfate, manganese chloride, cerium nitrate and water into the mixing device 10, Mix to obtain the catalyst active component solution; then transfer the catalyst active component solution to the reaction chamber 100 of the preparation device 20, and cool the catalyst active component solution to 0-5°C in the ice water bath 110 outside the reaction chamber 100, and then The oxalic acid solution in the oxalic acid pool 200 is added to the catalyst active component solution through the oxalic acid dropper 210, the reaction chamber 100 mixes and reacts during the stirring process to form a precipitate, and the precipitate is filtered, washed, and dried, and then added to the roasting device 30 for further processing. Roasting, the catalyst is prepared after calcination. ...

Embodiment 3

[0063]The basic content of this embodiment is the same as that of Embodiment 2, except that in step 400, during the preparation of the catalyst, additives are added to the calcined product, and then the mixture of the calcined product and the additive is added to the grinding device 40 for grinding , wherein the additives include potassium permanganate or potassium manganate, potassium permanganate or potassium manganate can decompose oxygen and manganese oxide under heating conditions, oxygen is beneficial to the catalytic effect, and manganese oxide is beneficial to supplement the consumption of catalyst manganese.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com