Preparation method of high-adhesion ink for photovoltaic glass coating

A photovoltaic glass, adhesion technology, applied in the direction of ink, application, household appliances, etc., can solve the problem that the reflectivity is not easy to reduce, speed up the speed of ball milling, etc., to avoid blisters, speed up the speed of ball milling, and avoid the effect of dry grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

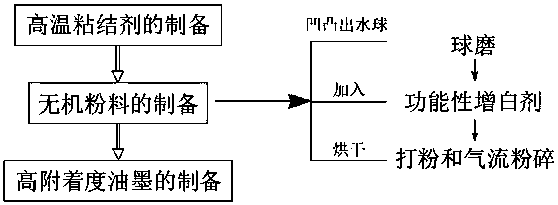

[0045] see figure 1 , a method for preparing a high-adhesion ink for photovoltaic glass coating, the high-adhesion ink includes inorganic powder and organic water-based varnish, the inorganic powder is made of high-temperature binder and functional whitening agent, The preparation method of high adhesion printing ink comprises the following steps:

[0046] S1. Preparation of high-temperature binder, uniformly mixing various inorganic raw materials according to a certain ratio, then adopting high-temperature melting and firing, and cooling the melt at high temperature through water quenching to obtain granular high-temperature binder;

[0047] S2. Preparation of inorganic powder: Grind the granular high-temperature binder to a certain fineness in a wet state, then put the functional whitening agent into the ball tube and wet mix together, fully and evenly mixed, and then bake Dry to obtain massive inorganic powder, which is then powdered and jet-milled to obtain a semi-finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com