Thermoplastic resin composition, preparation method and one application thereof

A thermoplastic resin and composition technology, which is applied in the field of thermoplastic resin composition and its preparation, can solve the problems of affecting the mechanical properties and heat resistance of styrene resins, reducing the gloss of ABS and ASA systems, increasing the interface, etc., to achieve good The effect of a matte finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in more detail through the following examples, but the present invention is not limited by the following examples.

[0048] The sources of raw materials used in the present invention are as follows:

[0049] Polypropylene: PP 7033N, ExxonMobil Chemical;

[0050] Styrene impact toughening agent:

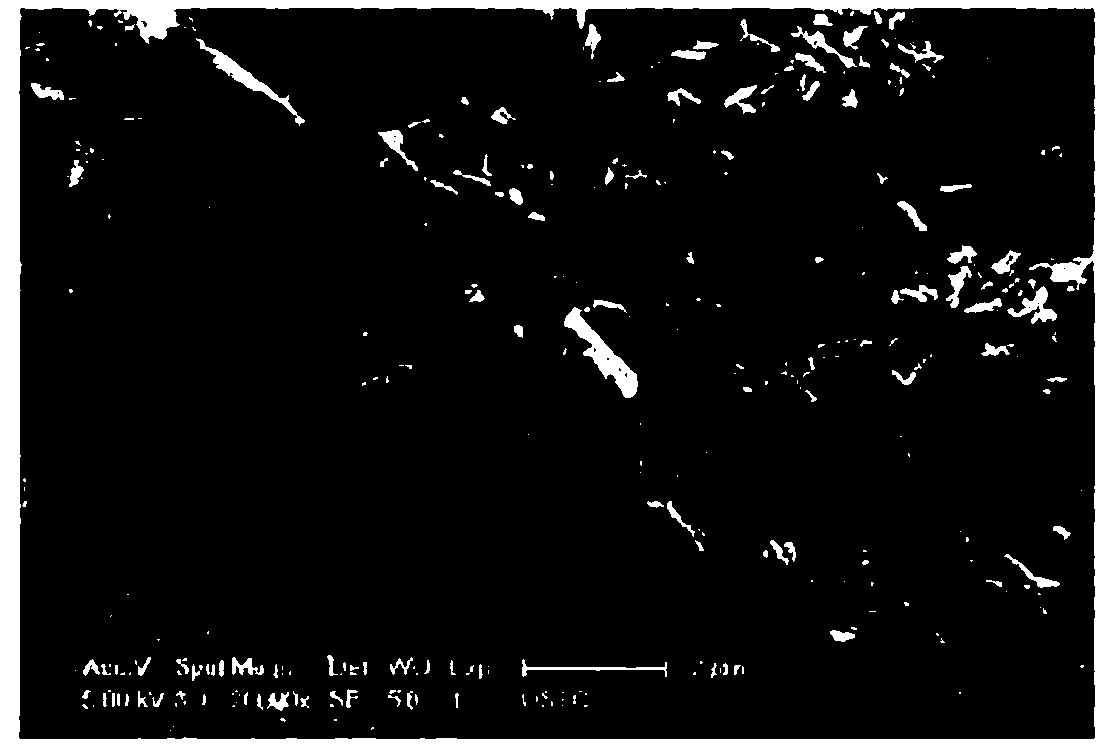

[0051] ABS-1: The butadiene content is 25%, the average particle size is 3.0 microns, produced by Gaoqiao Petrochemical;

[0052] ABS-2: Butadiene content is 25%, average particle size is 5.0 microns;

[0053] ASA: Acrylate content is 60%, average particle size is 0.6 microns, produced by UMG Corporation;

[0054] MBS: Butadiene content is 60%, average particle size is 0.3 microns, produced by LG Chem;

[0055] Copolymer of vinyl aromatic monomer and ethylenically unsaturated nitrile monomer:

[0056] SAN-1: Acrylonitrile content is 25 wt%, molecular weight is 250,000 Daltons, produced by Kumho Petrochemical;

[0057] SAN -2: Acrylonitrile content is 18 wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com