Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

A technology of reactive extrusion and low gloss, which is applied in the field of PC/ABS alloy and its preparation, can solve problems such as poor gloss stability, large fluctuations in mechanical properties, and deterioration of chemical properties, and achieve excellent matteness, good mechanical properties, and reduced material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

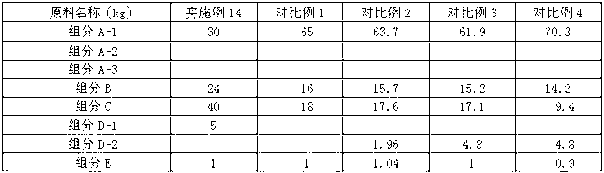

[0049] (1) Prepare materials according to the following components and weight percentage content:

[0050] Low-density polyethylene resin 96%, dicumyl peroxide 4%;

[0051] (2) First heat the dicumyl peroxide and control the temperature at 60-65°C to make it liquid;

[0052] (3) Pass low-density polyethylene resin (weight average molecular weight 40,000) through a twin-screw extruder, add dicumyl peroxide in a side-feeding manner, melt and extrude at a temperature of 160-200°C, and cool and granulate , to obtain the reactive extrusion matte agent.

Embodiment 2

[0054] (1) Prepare materials according to the following components and weight percentage content:

[0055] Linear low density polyethylene resin 97.5%, benzoyl peroxide 2.5%;

[0056] (2) First heat the benzoyl peroxide and control the temperature at 60-70°C to make it liquid;

[0057](3) Pass linear low-density polyethylene resin (weight average molecular weight 250,000) through a twin-screw extruder, add benzoyl peroxide in a side-feeding manner, melt and extrude at a temperature of 200-250°C, and cool and granulate , to obtain the reactive extrusion matte agent.

Embodiment 3

[0059] (1) Prepare materials according to the following components and weight percentage content:

[0060] High-density polyethylene resin 99.5%, di-tert-butyl peroxide 0.5%;

[0061] (2) First heat the di-tert-butyl peroxide and control the temperature at 70-80°C to make it liquid;

[0062] (3) Pass high-density polyethylene resin (weight average molecular weight 300,000) through a twin-screw extruder, add ditertbutyl peroxide in a side-feeding manner, melt and extrude at a temperature of 180-240°C, and cool and granulate , to obtain the reactive extrusion matte agent.

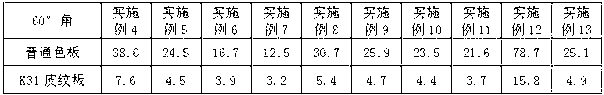

[0063] Preparation of Low Gloss PC / ABS Alloy Material

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com