Preparation method of high-insulation matte black polyimide film

A black polyimide, high-insulation technology, applied in the field of preparation of high-insulation matte black polyimide film, can solve the problems of easy formation of holes, poor carbon black dispersion, low insulation strength of the film, etc. Use requirements, high insulation use requirements, outstanding matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

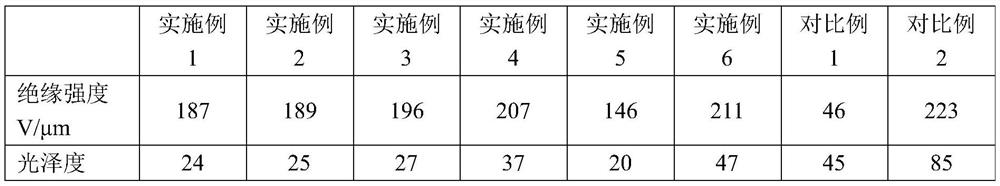

Examples

Embodiment 1

[0029] Preparation of high insulation matte black polyimide film:

[0030] S1, 5g polyaniline, 20g 4,4-diaminodiphenyl ether are added in 200g DMF, pass into N 2 Stir for 0.5h until the solution becomes clear, then add 21g of pyromellitic dianhydride in portions for reaction to obtain a polyaniline-polyamic acid blend solution with a viscosity of 100-250Pa S, wherein the polyaniline has a weight average molecular weight of 10 Ten thousand;

[0031] S2. Place the polyaniline-polyamic acid blend solution in a vacuum oven for degassing for 5 hours, pour it on a mirror-polished steel plate, and scrape off the film evenly;

[0032] S3. Heat the film at 160°C for 25 minutes, at 260°C for 6 minutes, at 370°C for 6 minutes, at 470°C for 5 minutes, and peel off after cooling to obtain a high-insulation matte black polyimide film.

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that the addition amount of polyaniline is 4g.

Embodiment 3

[0036] The difference between embodiment 3 and embodiment 1 is that the amount of polyaniline added is 3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com