Nanometer SiO2 super-hydrophobic coating and preparation process and application thereof

A super-hydrophobic coating and preparation technology, which is applied in coatings, photovoltaic power generation, electrical components, etc., can solve problems such as poor mechanical stability, poor coating transparency, and complicated preparation processes, and achieve low adhesion characteristics and simple equipment , enhance the effect of interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

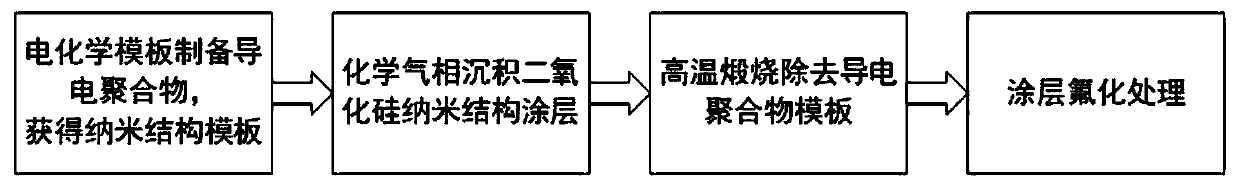

[0042] Preparation of nano-SiO 2 The steps of the superhydrophobic coating are as follows:

[0043] The first step: in the NaClO containing 0.1 ~ 0.2M 4 , or LiClO 4 , or LiClO 4 with NaClO 4 In the 0.01-0.05M EDOT / ACN solution with mixed salts in any proportion as the supporting electrolyte, the PEDOT film was directly electrodeposited on the ITO electrode by applying a cyclic potential between -0.5 and +1.6V by cyclic voltammetry; or by constant potential The PEDOT thin film is obtained by direct electrodeposition on the ITO electrode by applying any potential between +1.3 ~ +1.5V.

[0044] Step 2: Rinse with acetonitrile or ethanol polar organic solvent, dry it, put it in a closed container or desiccator, and put it into two small open containers at the same time, add 0.5-2mL tetraethoxysilane (TEOS) to one of them ), another 0.5-2mL ammonia solution with a concentration of 30%-38% was added, and the NH 3 Catalyzed TEOS hydrolysis and condensation reaction for 24-48 h...

Embodiment 2

[0048] The only difference with the embodiment is that the first step is: in the NaClO containing 0.1~0.2M 4 , or LiClO 4 , or LiClO 4 with NaClO 4 In the 0.1-0.5M PPy / CAN solution with mixed salts in any proportion as the supporting electrolyte, the PPy film was directly electrodeposited on the ITO electrode by applying a cyclic potential between -0.2 and +1.1V by cyclic voltammetry; or by constant potential Apply any potential between +0.8 ~ +1.0V to obtain PPy film by direct electrodeposition on the ITO electrode.

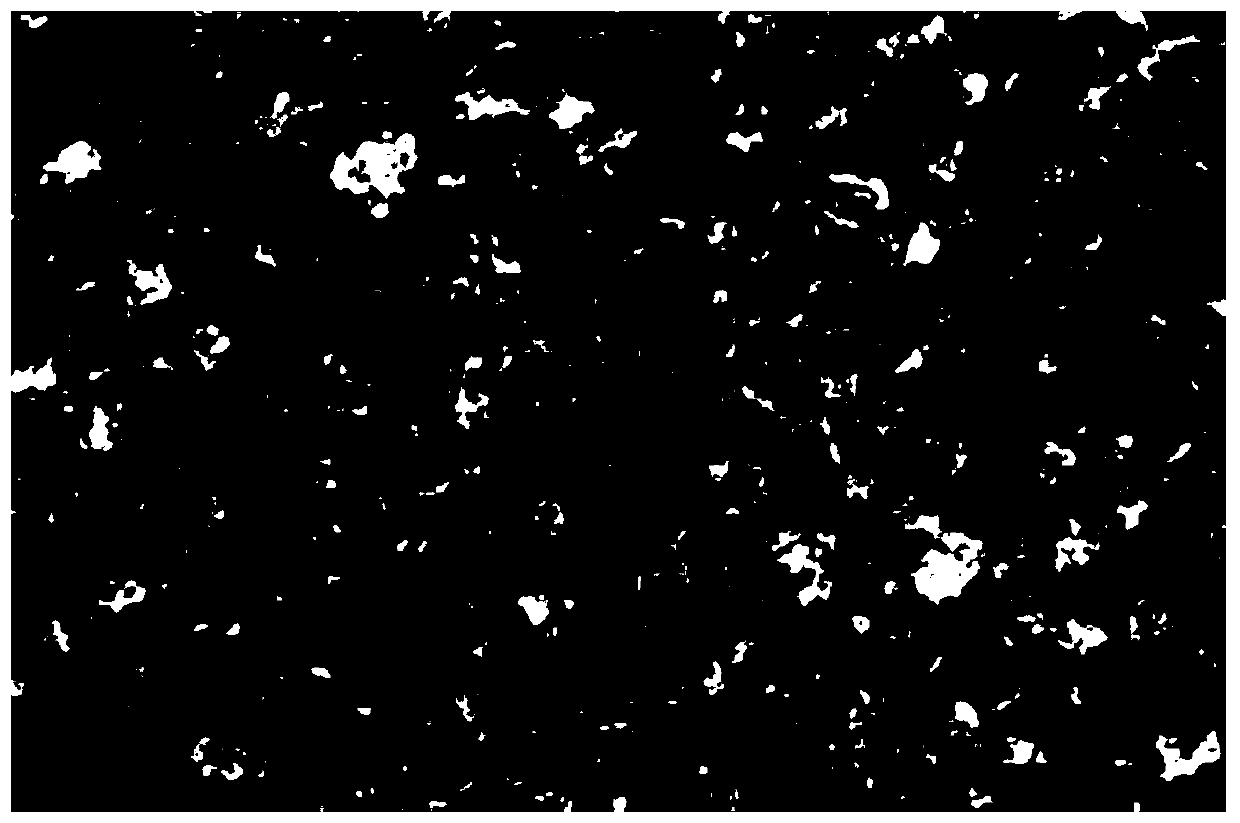

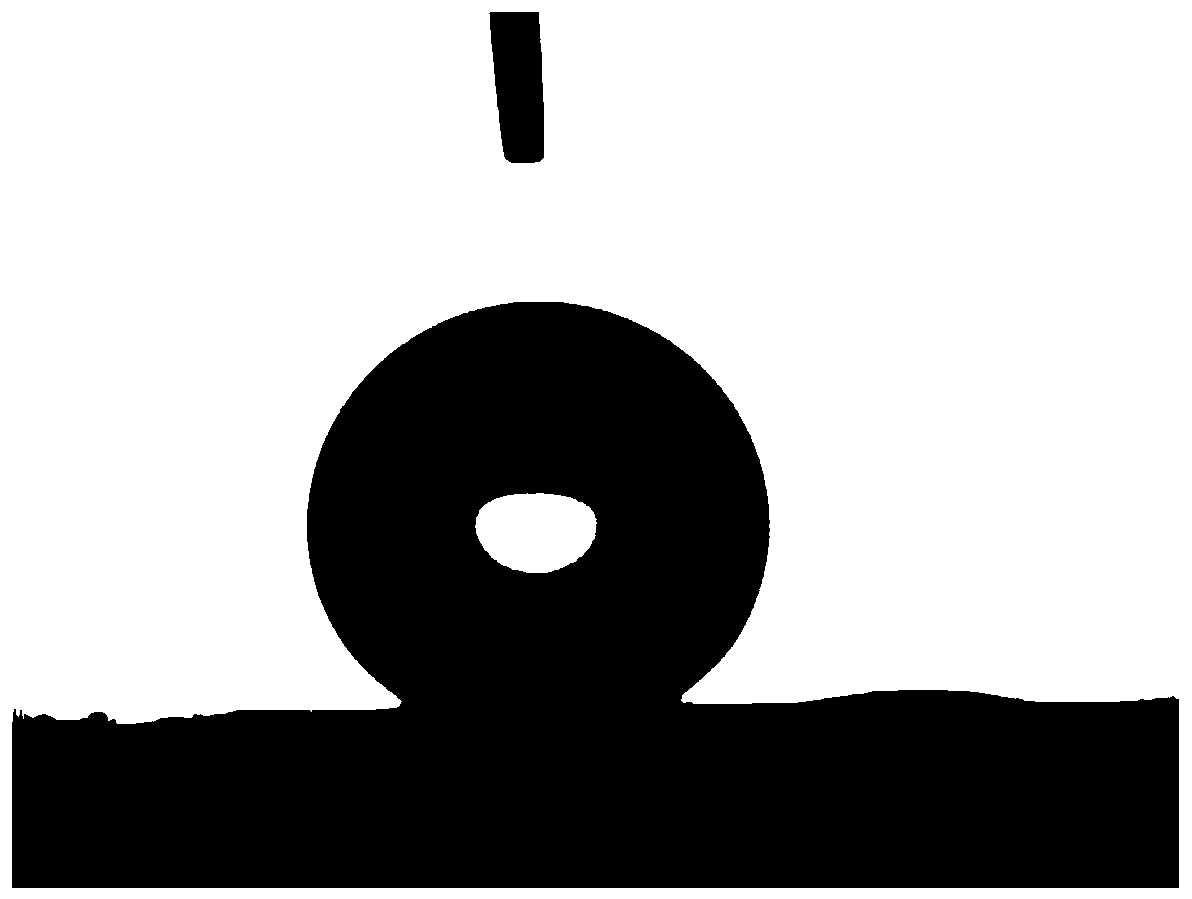

[0049] see Figure 2-4 , prepared nano-SiO 2 The microstructure, thermal and mechanical properties of the superhydrophobic coating are characterized as follows:

[0050] Calcined SiO using a field emission scanning microscope 2 Characterization of the coating microstructure, figure 2 shows that the prepared nano-SiO 2 The superhydrophobic coating retains the nano-rough structure morphology of the conductive polymer, and its particle thickness size is le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com