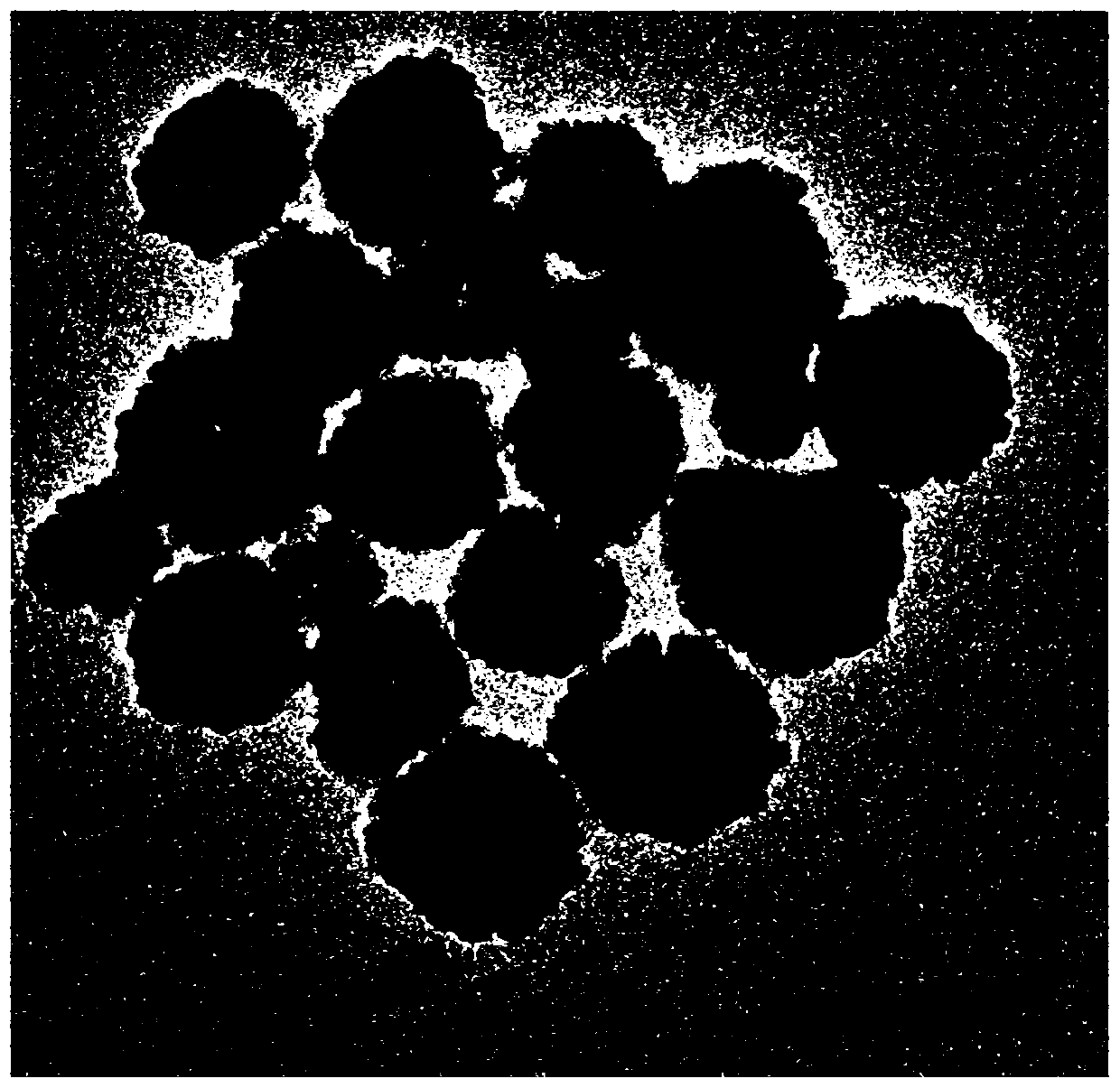

Preparation method of small-size iron disulfide nano hollow spheres

A technology of iron disulfide and hollow spheres is applied in the field of preparation of iron disulfide nanometer hollow spheres, which can solve the problems of difficulty in obtaining a small-sized hollow structure, and achieve the effects of simple method, easy availability of raw materials, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: this embodiment is a kind of preparation method of small-sized iron disulfide nano hollow spheres is completed according to the following steps:

[0031] One, iron stearate is dissolved in liquid paraffin, obtains iron stearate solution;

[0032] The massfraction of iron stearate in the ferric stearate solution described in step 1 is (1%~20%);

[0033] 2. Dissolving sulfur powder in oleic acid to obtain sulfur powder solution;

[0034] The mass fraction of sulfur powder in the sulfur powder solution described in step 2 is (1%~25%);

[0035] 3. Dispersing the surfactant into the liquid to obtain a surfactant solution;

[0036] The mass fraction of the surfactant in the surfactant solution described in step 3 is 0.1% to 3%;

[0037] 4. ①. Heat the iron stearate solution to 50°C to 80°C, then stir and react for 10min to 30min at a temperature of 50°C to 80°C and a stirring speed of 50r / min to 200r / min to obtain a reaction solution I;

[0038] ...

specific Embodiment approach 2

[0051] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of iron stearate in the iron stearate solution described in step one is (8%~10%). Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of sulfur powder in the sulfur powder solution described in step 2 is (8%-10%). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com