High-speed laser cladding method of boiler pipe and boiler pipe

A technology of laser cladding and boiler tubes, which is applied in coating, metal material coating technology, etc., can solve the problems of not being widely used, expensive, and difficult to implement, so as to simplify machining procedures, reduce material consumption, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

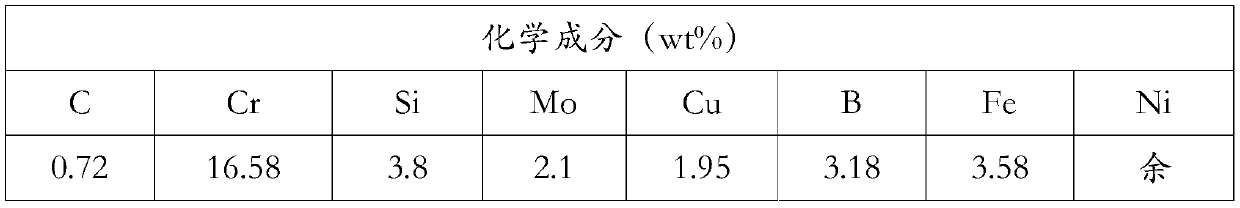

Embodiment 1

[0022] A high-speed laser cladding method for boiler tubes, the specific steps are as follows:

[0023] S1: Processing and testing before cladding. Machining the boiler tubes to be processed, testing the original specifications and sizes, and setting aside processing allowances according to technical requirements. The machining allowance is generally the diameter after cladding minus the diameter of the final product, and the machining allowance in this embodiment is not less than 0.2mm.

[0024] S2: Surface pretreatment, degreasing the workpiece to ensure the bonding between the cladding layer and the substrate. Specifically, use alcohol to wipe and sandpaper to polish the area to be clad to remove rust, oil and dirt.

[0025] S3: High speed cladding. Firstly, the boiler tube to be processed is placed on the lathe, clamped by the positioner, and positioned and aligned; then the robot grabs the laser and advances along the axis of the boiler tube with a step distance of 0.5...

Embodiment 2

[0030] A high-speed laser cladding method for boiler tubes, the specific steps are as follows:

[0031] S1: Processing and testing before cladding. Machining the boiler tubes to be processed, testing the original specifications and sizes, and setting aside processing allowances according to technical requirements. The machining allowance is generally the diameter after cladding minus the diameter of the final product, and the machining allowance in this embodiment is not less than 0.2 mm.

[0032] S2: Surface pretreatment, degreasing the workpiece to ensure the bonding between the cladding layer and the substrate. Specifically, use alcohol to wipe and sandpaper to polish the area to be clad to remove rust, oil and dirt.

[0033] S3: High speed cladding. Firstly, the boiler tube to be processed is placed on the lathe, clamped by the positioner, and positioned and aligned; then the robot grabs the laser and advances along the axis of the boiler tube with a step distance of 0....

Embodiment 3

[0038] A high-speed laser cladding method for boiler tubes, the specific steps are as follows:

[0039] S1: Processing and testing before cladding. Machining the boiler tubes to be processed, testing the original specifications and sizes, and setting aside processing allowances according to technical requirements. The machining allowance is generally the diameter after cladding minus the diameter of the final product, and the machining allowance in this embodiment is not less than 0.2mm.

[0040] S2: Surface pretreatment, degreasing the workpiece to ensure the bonding between the cladding layer and the substrate. Specifically, use alcohol to wipe and sandpaper to polish the area to be clad to remove rust, oil and dirt.

[0041] S3: High speed cladding. Firstly, the boiler tube to be processed is placed on the lathe, clamped by the positioner, and positioned and aligned; then the robot grabs the laser and advances along the axis of the boiler tube with a step distance of 1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com