Self-polishing antifouling anticorrosive coating for submarine cables

A technology for submarine cables and anti-corrosion coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as short service life, inability to protect submarine cables, poor adhesion performance, etc., and achieve anti-shear rate , Remarkable drag reduction effect, good retarding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

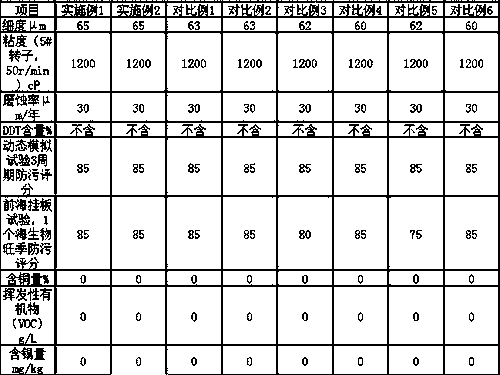

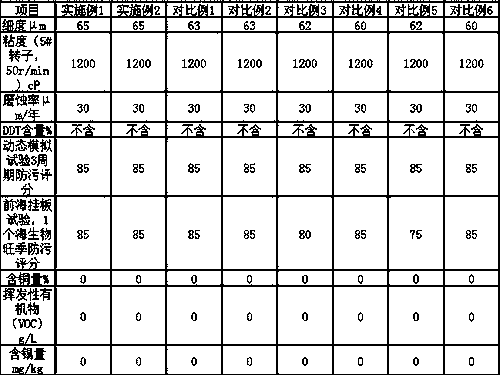

Examples

Embodiment 1

[0018] A self-polishing submarine cable anti-fouling and anti-corrosion coating, the preparation method thereof comprises the following steps: 1. Weigh each raw material according to the proportion, transfer vinyl ester resin preheated to 60°C into a reaction kettle, and raise the temperature of the reaction kettle When the temperature reaches about 90°C, add azobisisobutyronitrile and keep the temperature constant for 20 minutes; raise the temperature of the reactor to 120°C, and drop a certain amount of 2-acrylamide-2-methylpropanesulfonic acid slowly within 1 hour with a dropping funnel Aqueous solution, N-acryloylmorpholine, and acetic acid aqueous solution, after adding, add mercaptoethanol under nitrogen atmosphere, keep the temperature for 30 minutes, stop the reaction, and obtain modified vinyl ester resin; 2. Mix phthalic anhydride and dicyclopentan Put the diene into another reaction kettle, raise the temperature, stir, blow nitrogen, and drop pure water at 140°C for ...

Embodiment 2

[0025]A self-polishing submarine cable anti-fouling and anti-corrosion coating. The preparation method comprises the following steps: 1. Weigh each raw material according to the proportion, transfer vinyl ester resin preheated to 50-60°C into a reaction kettle, and react When the temperature of the kettle rises to about 90°C, add azobisisobutyronitrile and keep the temperature constant for 20 minutes; raise the temperature of the reactor to 120°C, and slowly add a certain amount of 2-acrylamide-2-methylpropane dropwise within 1 hour with a dropping funnel Sulfonic acid aqueous solution, N-acryloylmorpholine, and acetic acid aqueous solution, after adding, add mercaptoethanol under nitrogen atmosphere, then keep the temperature for 30 minutes, stop the reaction, and obtain modified vinyl ester resin; 2. Mix phthalic anhydride and Add dicyclopentadiene into another reaction kettle, heat up, stir, blow nitrogen, add pure water dropwise at 135°C for about 30-60 minutes, and keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com