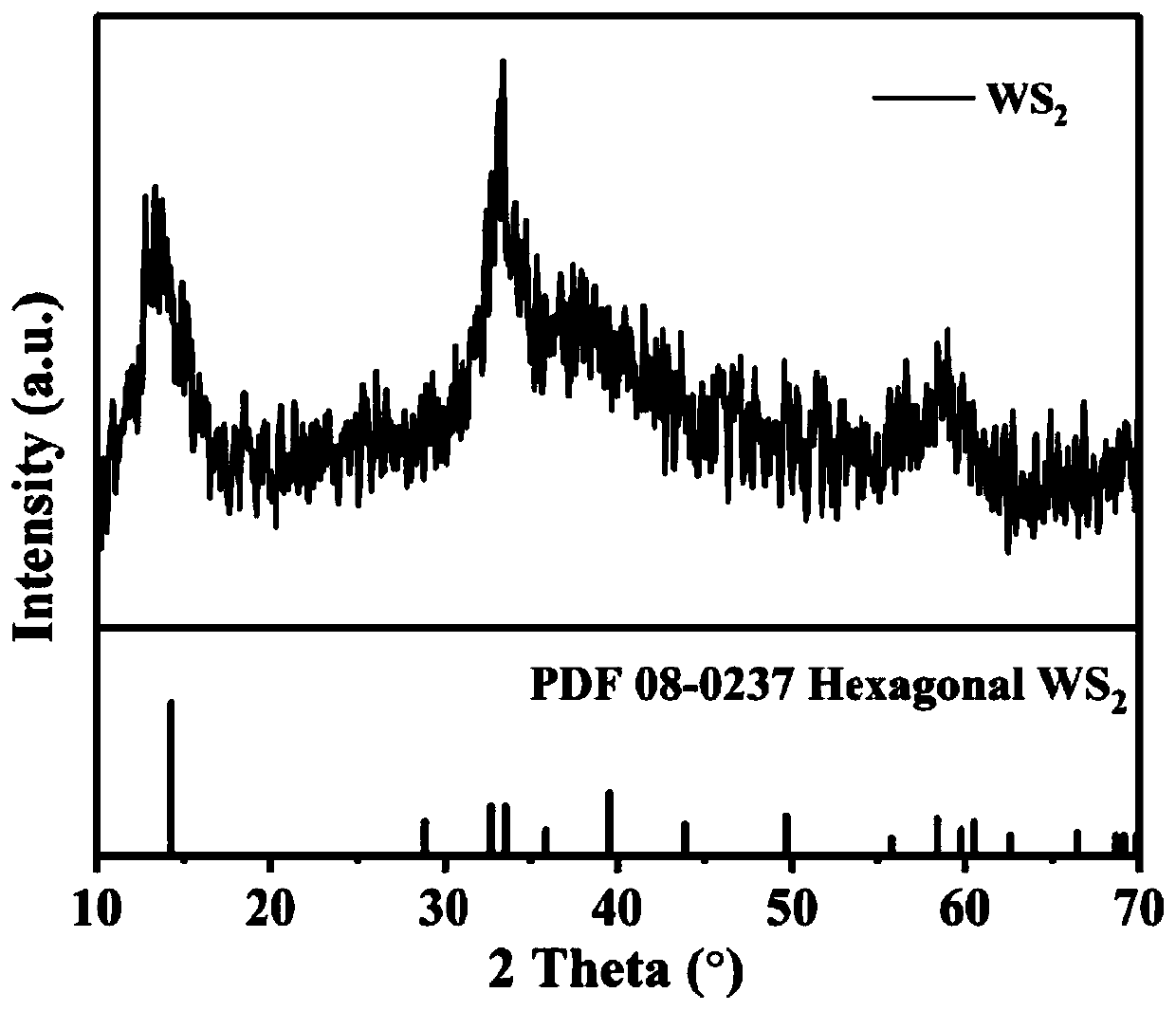

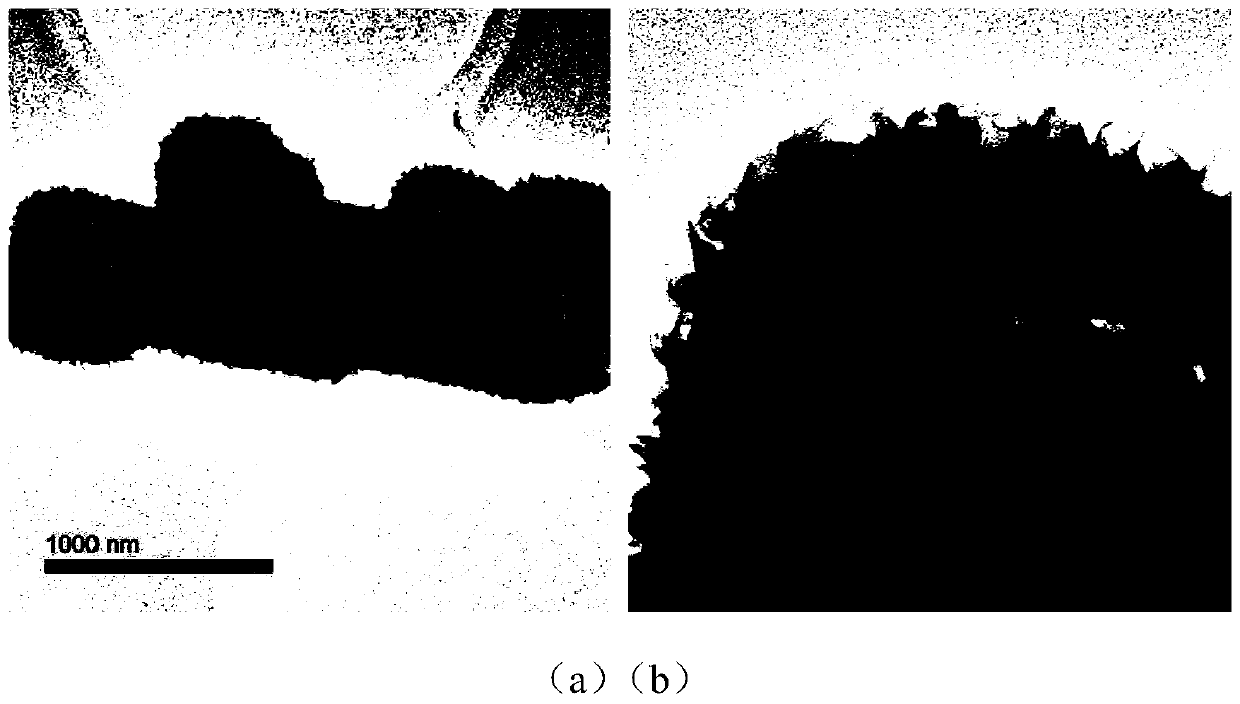

Self-assembled hollow tubular tungsten disulfide nano material as well as preparation method and application thereof

A technology of tungsten disulfide and nanomaterials, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of structural damage and collapse, poor cycle stability, low electron mobility, etc., and achieve increased contact area and reaction Effect of temperature control and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a self-assembled hollow tubular tungsten disulfide electrode material. Include the following steps:

[0030] Step 1: Take 0.2975-2.36g of tungsten hexachloride and 0.567-4.5g of thioacetamide and add it into 30-60mL of ethanol and magnetically stir until completely dissolved to form a blue-black suspension A. The stirring speed is 500-800r / min, and the stirring time is 30~120min. Control the molar ratio of tungsten source and sulfur source to be 1:10.

[0031] Step 2, add 0.27~1.08g glucose and 0.054~0.216g PVP to suspension A and stir until completely dissolved to obtain solution B, control the mass ratio of glucose and PVP to 5:1, and the molar ratio of sulfur source to glucose is ( 5~10): (1~3); the stirring speed is 500~800r / min, and the stirring time is 10~30min.

[0032] Step 3, transfer the above solution B to a 100mL polytetrafluoroethylene reactor for homogeneous reaction, the reaction temperature is 200-240°C, the reaction time is 4-4...

Embodiment 1

[0036] Step 1: Add 0.2975g tungsten hexachloride and 0.567g thioacetamide into 30mL ethanol solution and magnetically stir until completely dissolved to form a blue-black suspension A. The stirring speed is 500r / min and the stirring time is 30min. Control the mol ratio of tungsten hexachloride and thioacetamide to be 1:10;

[0037] Step 2: add 0.27g glucose and 0.054g PVP in suspension A and stir until fully dissolved, the mass ratio of control glucose and PVP is 5:1, and the molar ratio of thioacetamide and glucose is 5:1; Stirring speed is 700r / min, stirring time 10min.

[0038] Step 3: Transfer the above solution to a 100mL polytetrafluoroethylene reactor for homogeneous reaction. The reaction temperature is 200°C and the reaction time is 4h. After the reaction is completed, it is naturally cooled to room temperature.

[0039] Step 4: Open the reaction kettle, take out the product, wash it with absolute ethanol and deionized water in sequence, and centrifuge it. After repe...

Embodiment 2

[0042] Step 1: Add 2.36g of tungsten hexachloride and 4.5g of thioacetamide into 60mL ethanol solution and magnetically stir until completely dissolved to form a blue-black suspension A. The stirring speed is 800r / min and the stirring time is 120min. Control the molar ratio of tungsten hexachloride and thioacetamide to be 1:10.

[0043] Step 2: add 3.08g glucose and 0.616g PVP in suspension A and stir until fully dissolved, the mass ratio of controlling glucose and PVP is 5:1, and the molar ratio of thioacetamide and glucose is 7:2; Stirring speed is 800r / min, stirring time 20min.

[0044] Step 3: Transfer the above solution to a 100mL polytetrafluoroethylene reactor for homogeneous reaction. The reaction temperature is 220°C and the reaction time is 48h. After the reaction is completed, it is naturally cooled to room temperature.

[0045] Step 4: Open the reaction kettle, take out the product, wash with absolute ethanol and deionized water in sequence, and centrifuge, repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com