Method for regenerating metal from waste activated carbon

A technology for regenerating metals and activated carbon, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problem of high cost and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

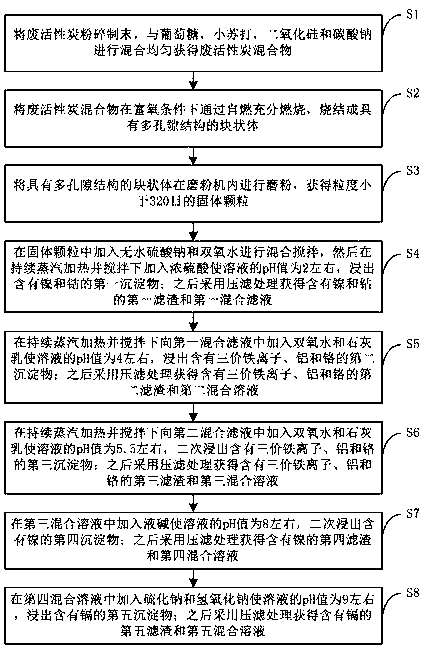

[0025] This embodiment provides a method for regenerating metals from waste activated carbon, such as figure 1 shown, including the following steps:

[0026] S1. Grinding the waste activated carbon into powder, and mixing them evenly according to the ratio of waste activated carbon powder: glucose: baking soda: silicon dioxide: sodium carbonate: 60:5: (0.1-0.3): 5:2 to obtain waste activated carbon mixture;

[0027] S2. Fully burn the waste activated carbon mixture through spontaneous combustion under oxygen-enriched conditions, and sinter it into a block with a porous structure; collect the smoke and dust generated during the combustion process, recover the metals in the dust, and perform harmless treatment on the waste gas discharge;

[0028] S3. Grinding the massive body with a porous structure in a mill to obtain solid particles with a particle size of less than 320 mesh;

[0029] S4. Add anhydrous sodium sulfate and hydrogen peroxide to the solid particles for mixing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com