Bar Image Inspection Mechanism

A technology of image detection and bar material, which is applied in the field of mechanism for online image detection of bar material, which can solve problems such as inability to grasp and rotate, too deep positioning groove, complex detection mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

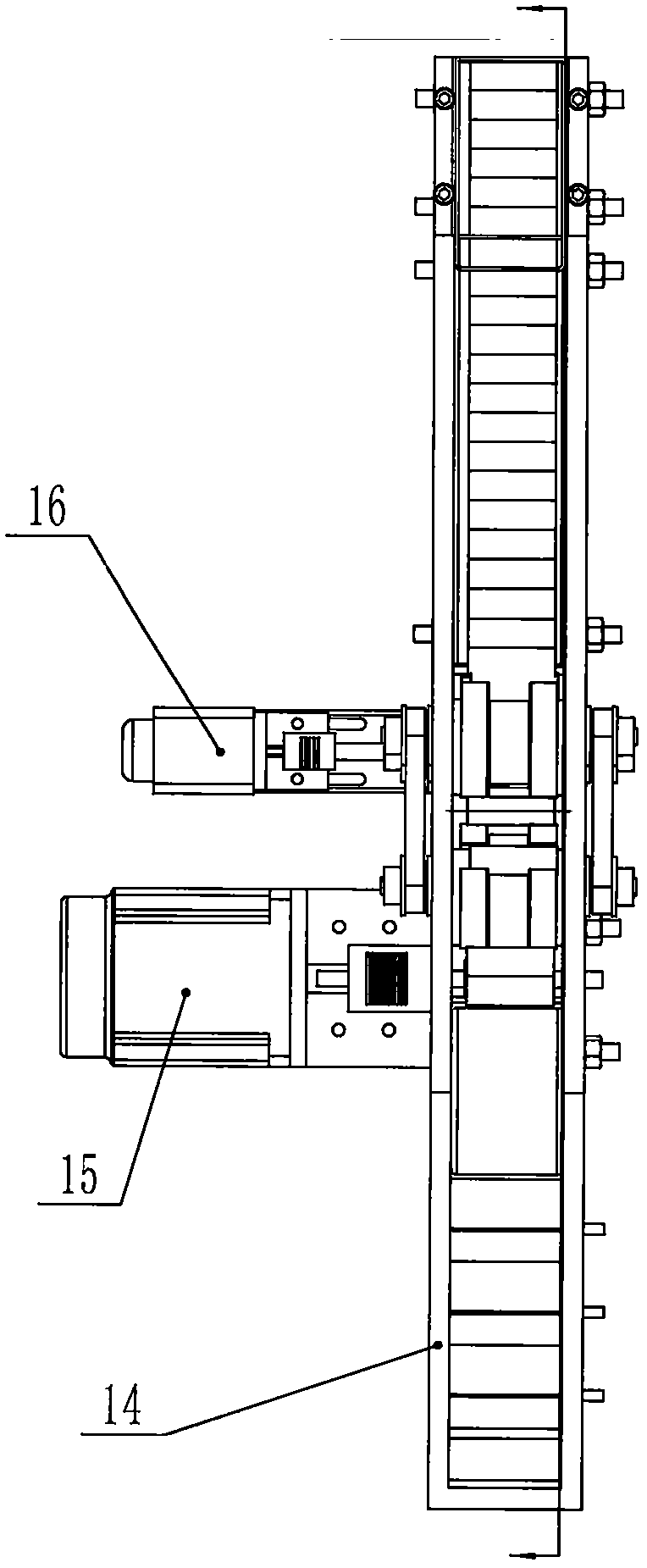

Image

Examples

Embodiment Construction

[0011] The implementation and operation process of the present invention are as follows: put the bar to be detected (4) into the storage box (3), start the feeding motor (15), the rotating motor (16), feed the synchronous belt (1) and feed Material transfer wheel (5), discharge material transfer wheel (9) run. The bar (4) reaches the edge of the feed transfer wheel (5) driven by the feed timing belt (1). Parallel card slots, the depth of the card slots can prevent the bar from falling off after the bar is stuck. The transfer wheels (5), (9) are fixed with an eccentric wheel (6) eccentric to it, and the center of the eccentric wheel (6) is biased towards the discharge position, so that the distance between the transfer wheels (5), (9) and the outer circumference of the eccentric wheel (6) is the largest when the feed transfer wheels (5), (9) are feeding, and the transfer wheels (5), (9) The distance from the outer circumference of the eccentric wheel (6) is the smallest to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com