Method for preparing potassium perchlorate powder by using closed-loop spray dryer

A technology of spray dryer and potassium perchlorate, applied in the directions of perchloric acid, perchlorate, spray evaporation, etc., can solve the problems of complicated and complicated production process, high impurity content of products, increase enterprise cost, etc., so as to solve the problem of complicated production process Complicated, easy to industrialize production, ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

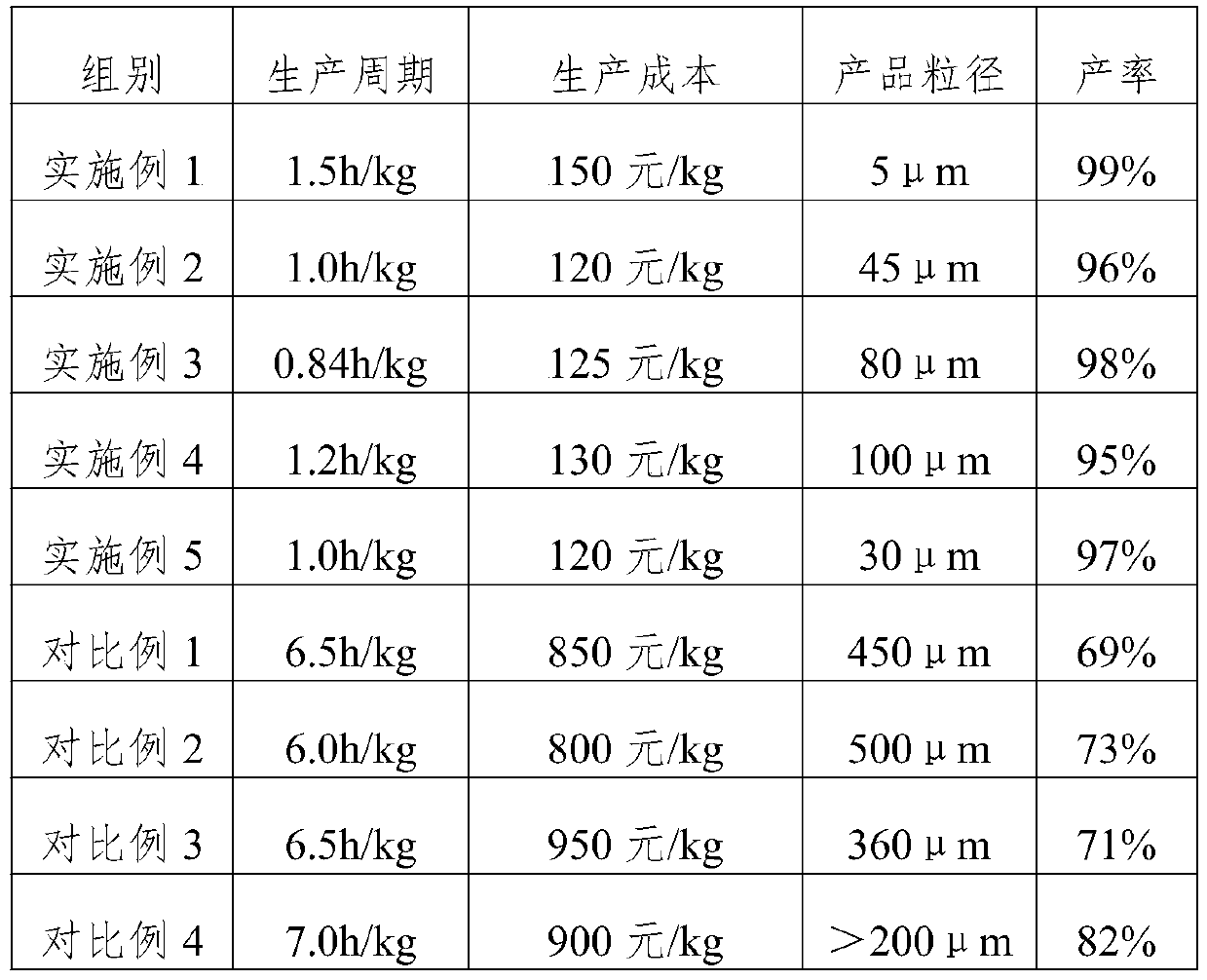

Examples

Embodiment 1

[0031] A kind of method utilizing closed circuit spray drier to prepare potassium perchlorate powder, comprises the following steps:

[0032] (1) First add deionized water into the blending tank, then add potassium perchlorate solid, stir for 10 minutes to 30 minutes, filter with a microporous filter, collect the filtrate, and obtain potassium perchlorate solution;

[0033] The aperture of described microporous filter is 0.2 μm~1 μm; The purity of described potassium perchlorate solid is greater than 90%, and its volume ratio with deionized water is 1:(60~100); The quality of described potassium perchlorate solution The concentration is 1.0%~1.6%;

[0034] (2) the above-mentioned potassium perchlorate solution made is pumped into the feed liquid chamber of the closed-circuit circulation spray dryer, and the drying system is controlled. When the oxygen concentration of the drying system is about to 0.2% to 2.5%, the feed diaphragm pump is started. Control the flow rate to 0.2m...

Embodiment 2

[0037] The difference from Example 1 is that the mass concentration of the potassium perchlorate solution is 1.3%, and other conditions remain unchanged.

Embodiment 3

[0039] Difference with Example 1 is: the purity of described potassium perchlorate solid is greater than 90%, and its volume ratio with deionized water is 1:80, and the time of stirring after adding potassium perchlorate solid is 20min, other conditions are not Change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com