Method for preparing semi-continuous ternary precursor

A semi-continuous, precursor technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of uneven particle size distribution, complex process, low product activity, etc., and achieve effective narrowing of particle size distribution, shrinking Effect of narrow particle size distribution and increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

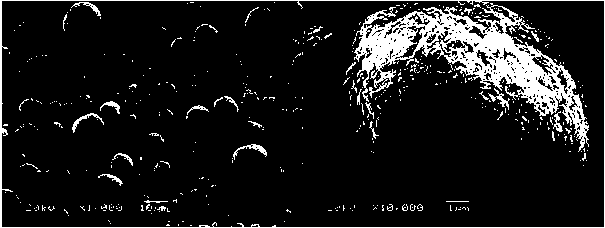

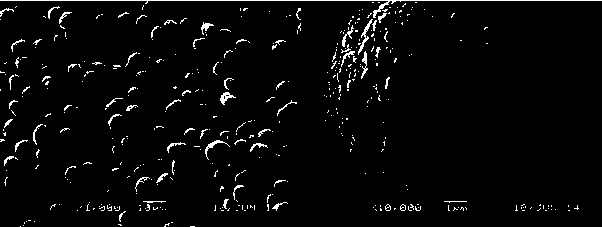

[0030] Ni 0。5 co 0.2 mn 0.3 (OH) 2 : d10=5.1um, d50=10.06um, d90=15.78um, tap density=2.25g / cm 3 , specific surface area = 6.52m 2 / g, which is spherical.

[0031] (1) According to the molar ratio of Ni:Co:Mn 5:2:3, prepare a mixed aqueous solution of nickel-cobalt-manganese soluble salt with a total concentration of 2.0mol / L, and use liquid caustic soda with a concentration of 32% as a precipitant with a concentration of 20%. Aqueous ammonia solution as complexing agent;

[0032] (2) Adjust the stirring speed of the 6500L reactor to 300r / min, and use a precision metering pump to add 2.0mol / L nickel-cobalt-manganese soluble salt solution, 32% liquid caustic soda and 20% ammonia solution into the reactor in parallel , control salt flow to 300L / h, control OH -The molar ratio of / (Ni+Co+Mn)=1.9, the temperature of the reactor is controlled at 60°C, the concentration of ammonia is controlled at 8.5g / L, the speed of the concentrator is controlled at 75r / min, and the effectiv...

Embodiment 2

[0039] Ni 0。5 co 0.2 mn 0.3 (OH) 2 : d10=5.8um, d50=10.16um, d90=14.71um, tap density=2.4g / cm 3 , specific surface area = 6.1m 2 / g, which is spherical.

[0040] (1) According to the molar ratio of Ni:Co:Mn 5:2:3, prepare a mixed aqueous solution of nickel-cobalt-manganese soluble salt with a total concentration of 2.0mol / L, and use liquid caustic soda with a concentration of 32% as a precipitant with a concentration of 20%. Aqueous ammonia solution as complexing agent;

[0041] (2) Adjust the stirring speed of the 6500L reactor to 300r / min, and use a precision metering pump to add 2.0mol / L nickel-cobalt-manganese soluble salt solution, 32% liquid caustic soda and 20% ammonia solution into the reactor in parallel , control salt flow to 300L / h, control OH - The molar ratio of / (Ni+Co+Mn)=1.9, the temperature of the reactor is controlled at 60°C, the concentration of ammonia is controlled at 8.5g / L, the speed of the concentrator is controlled at 75r / min, and the effective...

Embodiment 3

[0048] Ni 0。5 co 0.2 mn 0.3 (OH) 2 : d10=7.54um, d50=10.02um, d90=13.21um, tap density=2.36g / cm 3 , specific surface area = 5.91m 2 / g, which is spherical.

[0049] (1) According to the molar ratio of Ni:Co:Mn 5:2:3, prepare a mixed aqueous solution of nickel-cobalt-manganese soluble salt with a total concentration of 2.0mol / L, and use liquid caustic soda with a concentration of 32% as a precipitant with a concentration of 20%. Aqueous ammonia solution as complexing agent;

[0050] (2) Adjust the stirring speed of the 6500L reactor to 300r / min, and use a precision metering pump to add 2.0mol / L nickel-cobalt-manganese soluble salt solution, 32% liquid caustic soda and 20% ammonia solution into the reactor in parallel , control salt flow to 300L / h, control OH - The molar ratio of / (Ni+Co+Mn)=1.9, the temperature of the reactor is controlled at 60°C, the concentration of ammonia is controlled at 8.5g / L, the speed of the concentrator is controlled at 75r / min, and the effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com