Application of ion gel in graphene transfer and graphene transistor fabrication, graphene transistor and fabrication method of graphene transistor

An ion gel and graphene technology, applied in the field of graphene, can solve the problems such as the inability of PMMA to be completely cleaned, the effective width of the transistor channel is narrowed, and the performance of the transistor is affected. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

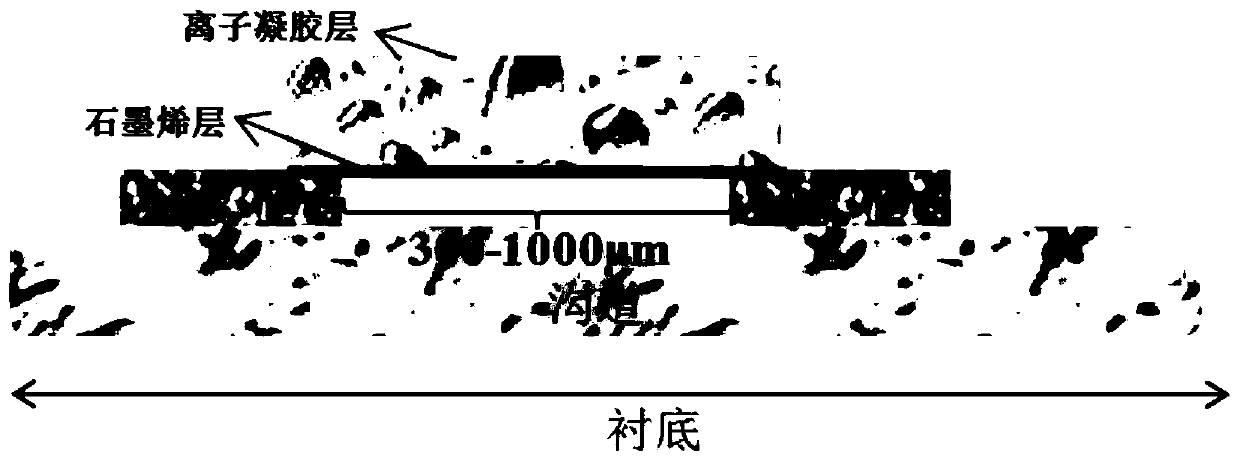

[0054] In a fourth aspect, the present invention provides a method for preparing a graphene transistor, the method comprising:

[0055] (1) preparing a substrate with a drain and a source, wherein a channel is provided between the drain and the source;

[0056] (2) Transfer the ion gel / graphene layer to the channel according to the graphene transfer method described above, and make the graphene layer contact with the drain electrode and the source electrode respectively , and then initiate the polymerization of polyethylene glycol diacrylate monomer under the condition that the initiator can act, so as to obtain the graphene transistor.

[0057] According to the present invention, the substrate can be a conventional substrate in the art for preparing graphene transistors, for example, it can be formed by crossing a metal layer on a silicon wafer or PET (polyethylene terephthalate). the substrate. Preferably, the substrate has a thickness of 4-6 mm and a length of 1-3 cm.

...

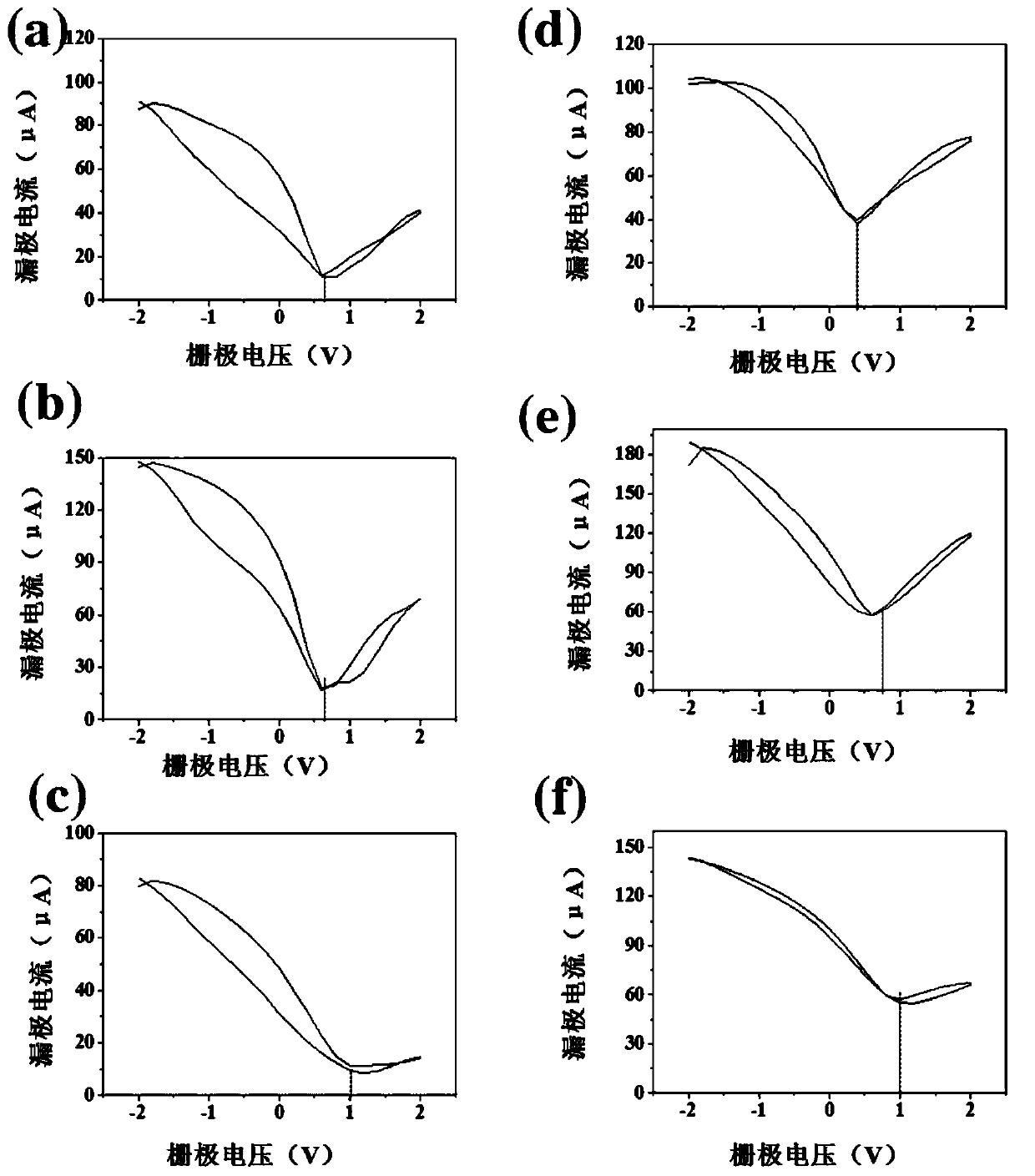

Embodiment 1-3

[0076] For illustrating the preparation method of the graphene transistor provided by the present invention

[0077] (1) Preparation of single-layer graphene by chemical vapor deposition

[0078] Copper foil (10cm×10cm, 25μm, Sigma) was first treated with piranha solution (H 2 SO 4 with H 2 o 2 (with a mixture of 7:3) for 15 minutes. It was then rinsed again by immersion in deionized water, and dried with nitrogen. Then add the cleaned copper foil into the quartz tube exhausted of air, when the internal pressure of the quartz tube reaches 5×10 -3 When Torr, pass H 2 , while heating the quartz tube to 1000°C for 30 minutes, then continuously injecting H 2 (flow velocity 10sccm), feed the CH with a flow velocity of 5sccm 4 gas, making the graphene grow continuously. After 30min, stop feeding CH 4 , the quartz tube at H 2 Cool to room temperature in a stream. Single-layer graphene grown on copper foil was obtained.

[0079] (2) Preparation of gold electrodes

[0080...

Embodiment 4

[0086] This comparative example is used to illustrate the preparation method of the graphene transistor of reference

[0087] The preparation of the graphene transistor is carried out according to the method of Example 1, the difference is that the ionic liquid [EMIM][TFSI] is still used, but the ratio is not according to Example 1. The weight part of ionic liquid is 92%, the weight part of polymer PEGDA is 7%, the weight part of photoinitiator HOMPP is 1%, and the curing of ion gel is not complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com