Degreasing system and degreasing method of heat exchanger

A grease and controller technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, flushing, etc., can solve the problems of high temperature oxidation of heat exchanger tubes, large space occupation, high temperature oxidation of heat exchange tubes, etc., to achieve rapid blowing, Small footprint and high degreasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

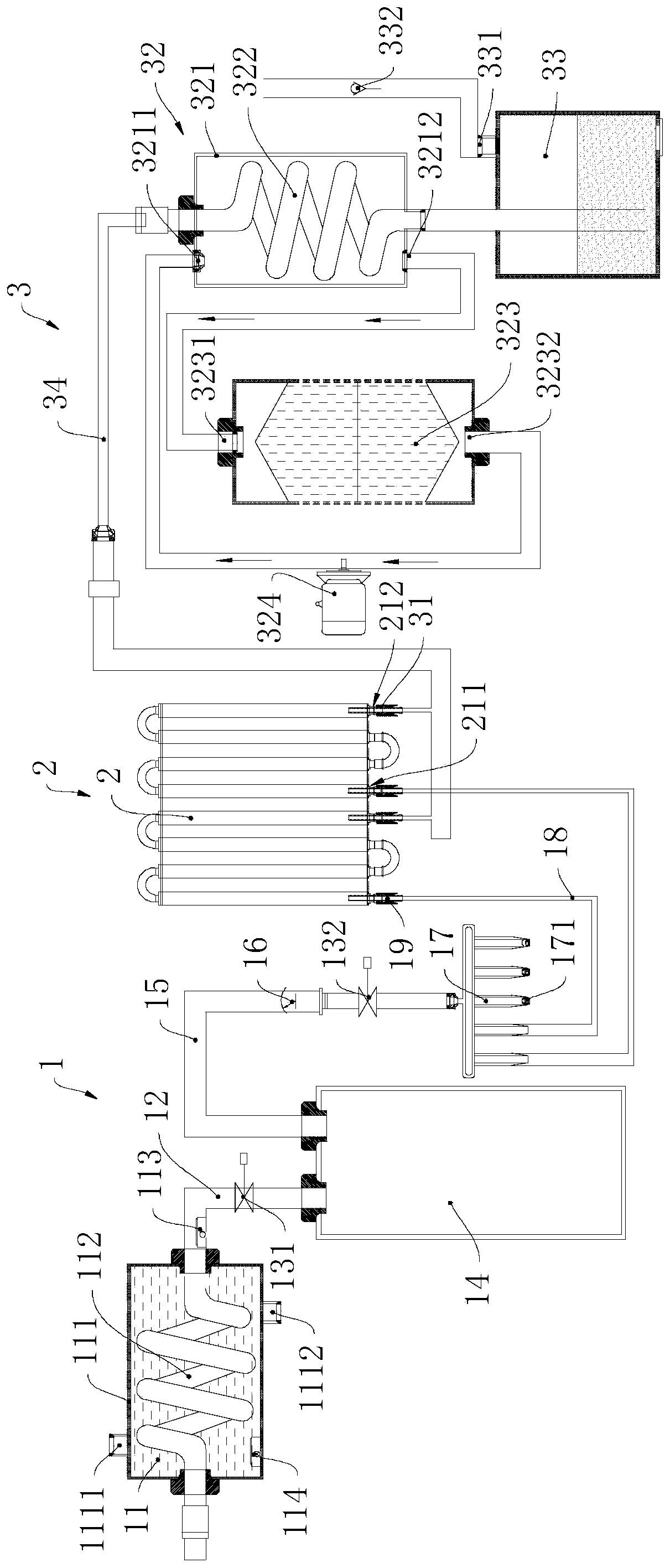

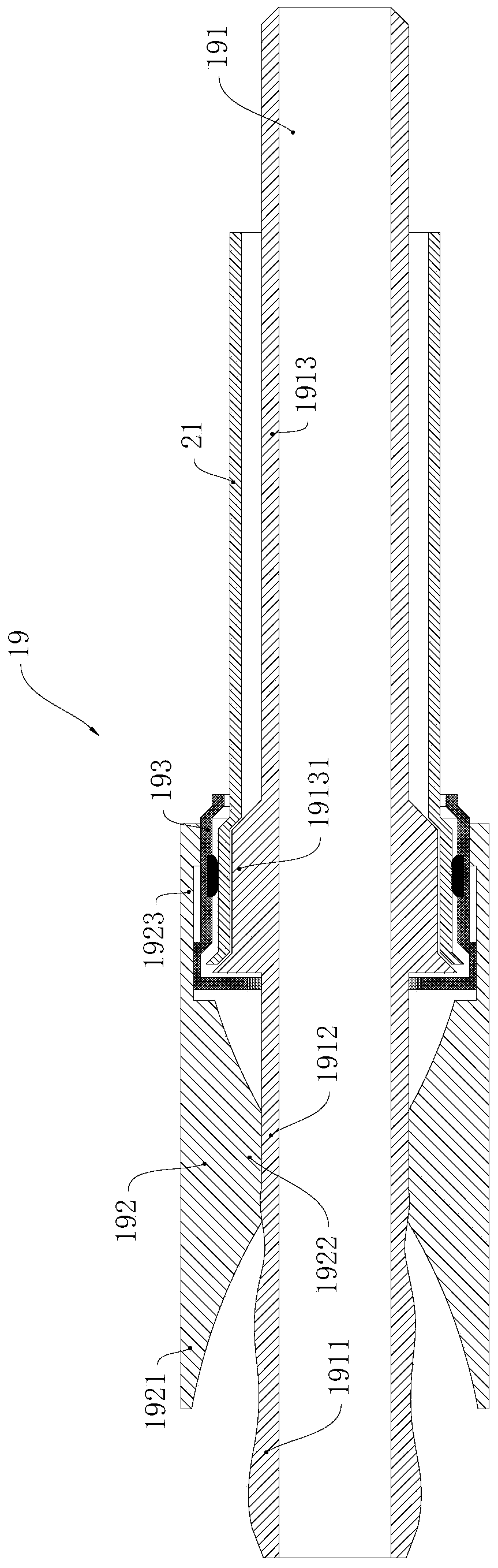

[0041] The degreasing method of the heat exchanger of this embodiment is applied to the degreasing system of this embodiment, please refer to figure 1, the degreasing system of this embodiment is used for degreasing the heat exchanger 2, the heat exchange tube 21 of the heat exchanger 2 has a first nozzle 211 and a second nozzle 212, and the degreasing system includes an air compressor (not shown in the figure) Shown), the air intake unit 1 and the grease processing unit 3, the air compressor can specifically be an air compressor with a constant output pressure, the air compressor is connected to the upstream of the air intake unit 1, and the heat exchanger 2 is degreased using a degreasing system During processing, the first nozzle 211 of the heat exchange tube 21 is connected to the air intake unit 1, the second nozzle 212 of the heat exchange tube 21 is connected to the grease processing unit 3, the air compressor, the air intake unit 1, and the heat exchange tube 21 And th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com