A low-carbon and low-emission sintering method based on multi-type gas coupling injection

A sintering method and low-emission technology, which is applied in the field of iron and steel metallurgy, can solve the problems of short residence time at high temperature, large heat storage, over-melting sintering temperature, etc., and achieve the effect of increasing sintering output, increasing the degree of reduction, and reducing NOX

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

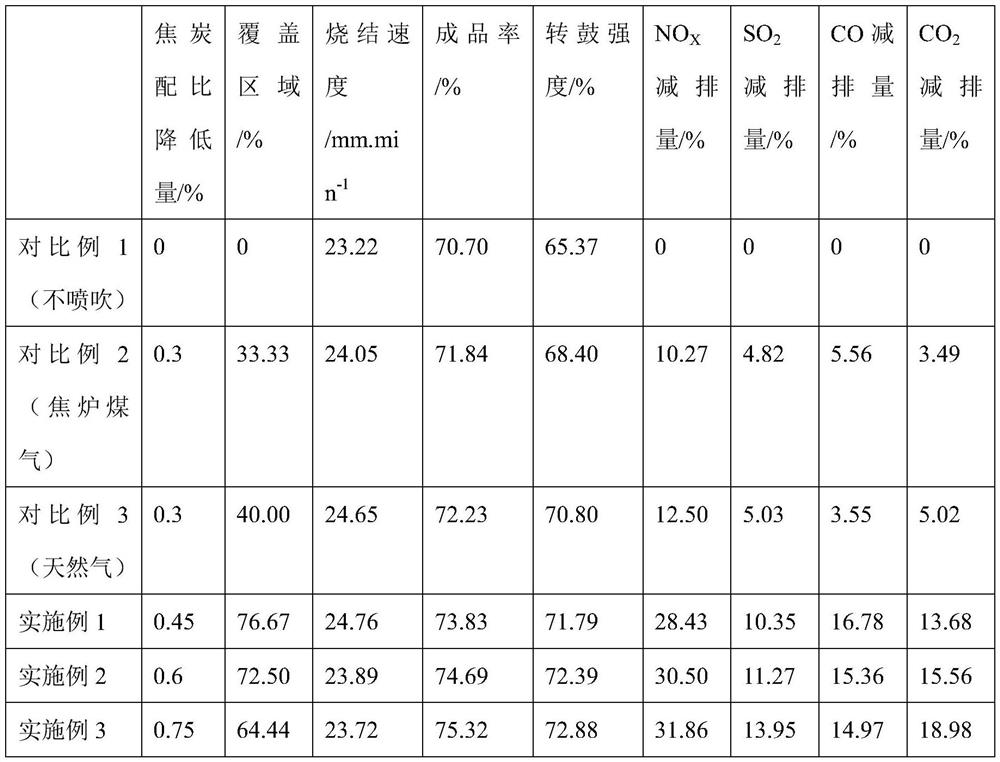

Embodiment 1

[0028] A method for intensified sintering of multi-type gas coupling injection of the present invention, under the conditions of 5.6% carbon content of the mixture, 1.85 binary basicity, 6.75% sintering moisture, and 700mm material layer height, the maximum temperature from the sintering material surface is The area between 1250°C and 1250°C is area I, the area between 1250°C and 1300°C is area II, and the area between 1300°C and 1350°C is area III. Under the sintering cup test with the same other conditions, the heat value injected into area Ⅰ is 35MJ / Nm 3 Gas with high calorific value, the calorific value injected into zone Ⅱ is 18MJ / Nm 3 medium calorific value gas, zone Ⅲ injected calorific value 11MJ / Nm 3 Low calorific value gas, and reduce the carbon content of the mixture to 5.15%. Sintering index, NO X , SO 2 and CO X The emission reductions are shown in Table 1.

Embodiment 2

[0030]A method for intensified sintering with multi-type gas coupling injection of the present invention, under the conditions of 5.6% carbon content of the mixture, 1.85 binary basicity, 6.75% sintering moisture, and 800mm material layer height, the maximum temperature from the sintering material surface is The area between 1250°C and 1250°C is area I, the area between 1250°C and 1300°C is area II, and the area between 1300°C and 1350°C is area III. Under the sintering cup test with the same other conditions, the heat value injected into area Ⅰ is 42MJ / Nm 3 The gas with high calorific value is injected into zone II with a calorific value of 25MJ / Nm 3 medium calorific value gas, zone Ⅲ injected calorific value 13MJ / Nm 3 Low calorific value gas, and reduce the carbon content of the mixture to 5.0%.

Embodiment 3

[0032] A method for intensified sintering of multi-type gas coupling injection of the present invention, under the conditions of 5.6% carbon content of the mixture, 1.85 binary basicity, 6.75% sintering moisture, and 900mm material layer height, the maximum temperature from the sintering material surface is The area between 1250°C and 1250°C is area I, the area between 1250°C and 1300°C is area II, and the area between 1300°C and 1350°C is area III. Under the sintering cup test with the same other conditions, the heat value injected into area Ⅰ is 50MJ / Nm 3 The gas with high calorific value is injected into the area II with a calorific value of 28MJ / Nm 3 medium calorific value gas, zone Ⅲ injected calorific value 13MJ / Nm 3 Low calorific value gas, and reduce the carbon content of the mixture to 4.85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com