Gasoline cleaning synergist

A synergist, cleansing and dispersing agent technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as adverse effects on human health, entering the air, polluting the environment, and achieve low cost, reduced wear, and The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

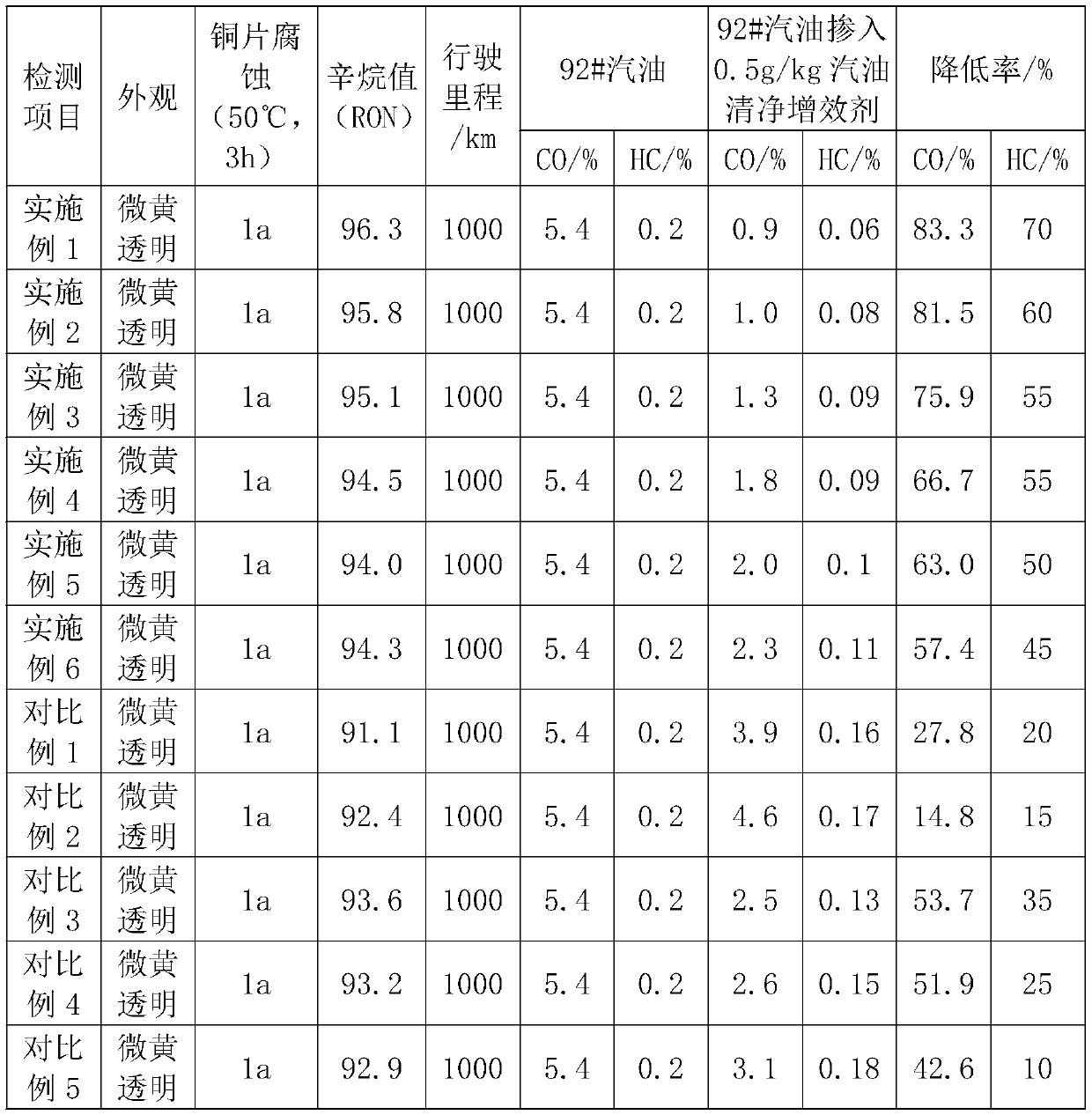

Examples

Embodiment 1

[0032] In this embodiment, the gasoline detergent synergist is made from the following raw materials in parts by weight: 19 parts of solvent oil, 19 parts of plasticizer, 3.4 parts of friction modifier, 43 parts of oxidant, and 5 parts of lubricant to improve cleaning 10.4 parts of dispersants and 0.2 parts of combustion aids; the solvent oil is 1500 benzene solvent naphtha, the plasticizer is biphenyl, the friction modifier is palmitic acid, and the oxidizer is peroxide, and the lubricant It is an organic nitrogen molybdenum fullerene fullerene lubricant, and the combustion promoter is octyl ferrocene.

[0033] The improved detergent and dispersant is obtained through the following steps:

[0034] S1: Add polyetheramine: absolute ethanol: silica gel: silicone resin in a ratio of 10:3:1:1 to the stirring tank to disperse to obtain a uniform mixed solution;

[0035] S2: Dry and granulate the above mixed solution with a spray dryer to prepare an improved detergent and dispersan...

Embodiment 2

[0042] The preparation method of the improved detergent and dispersant and gasoline detergent synergist in this embodiment is the same as that in Example 1, and will not be repeated here.

[0043] In this embodiment, the gasoline detergent synergist is made from the following raw materials in parts by weight: 20.4 parts of solvent oil, 19 parts of plasticizer, 3.4 parts of friction modifier, 43 parts of oxidizing agent, and 5 parts of lubricant to improve cleaning 9 parts of dispersants and 0.2 parts of combustion aids; the solvent oil is 1500 benzene solvent naphtha, the plasticizer is biphenyl, the friction modifier is palmitic acid, the oxidant is peroxide, and the lubricant It is an organic nitrogen molybdenum fullerene fullerene lubricant, and the combustion promoter is octyl ferrocene.

Embodiment 3

[0045] The preparation method of the improved detergent and dispersant and gasoline detergent synergist in this embodiment is the same as that in Example 1, and will not be repeated here.

[0046] In this embodiment, the gasoline detergent synergist is made from the following raw materials in parts by weight: 17.4 parts of solvent oil, 19 parts of plasticizer, 3.4 parts of friction modifier, 43 parts of oxidizing agent, and 5 parts of lubricant to improve cleaning 12 parts of dispersants and 0.2 parts of combustion aids; the solvent oil is 1500 benzene solvent naphtha, the plasticizer is biphenyl, the friction modifier is palmitic acid, the oxidizing agent is peroxide ether, and the lubricant It is an organic nitrogen molybdenum fullerene fullerene lubricant, and the combustion promoter is octyl ferrocene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com