Vertical type rapid heating device for euphausia superba

A technology of rapid heating and Antarctic krill, applied in food science, animal feed, animal feed, etc., can solve the problems of lack of material propulsion, no heating function of the spindle, complex equipment structure, etc., to avoid krill sticking to the wall , compact structure, and the effect of improving the uniformity of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

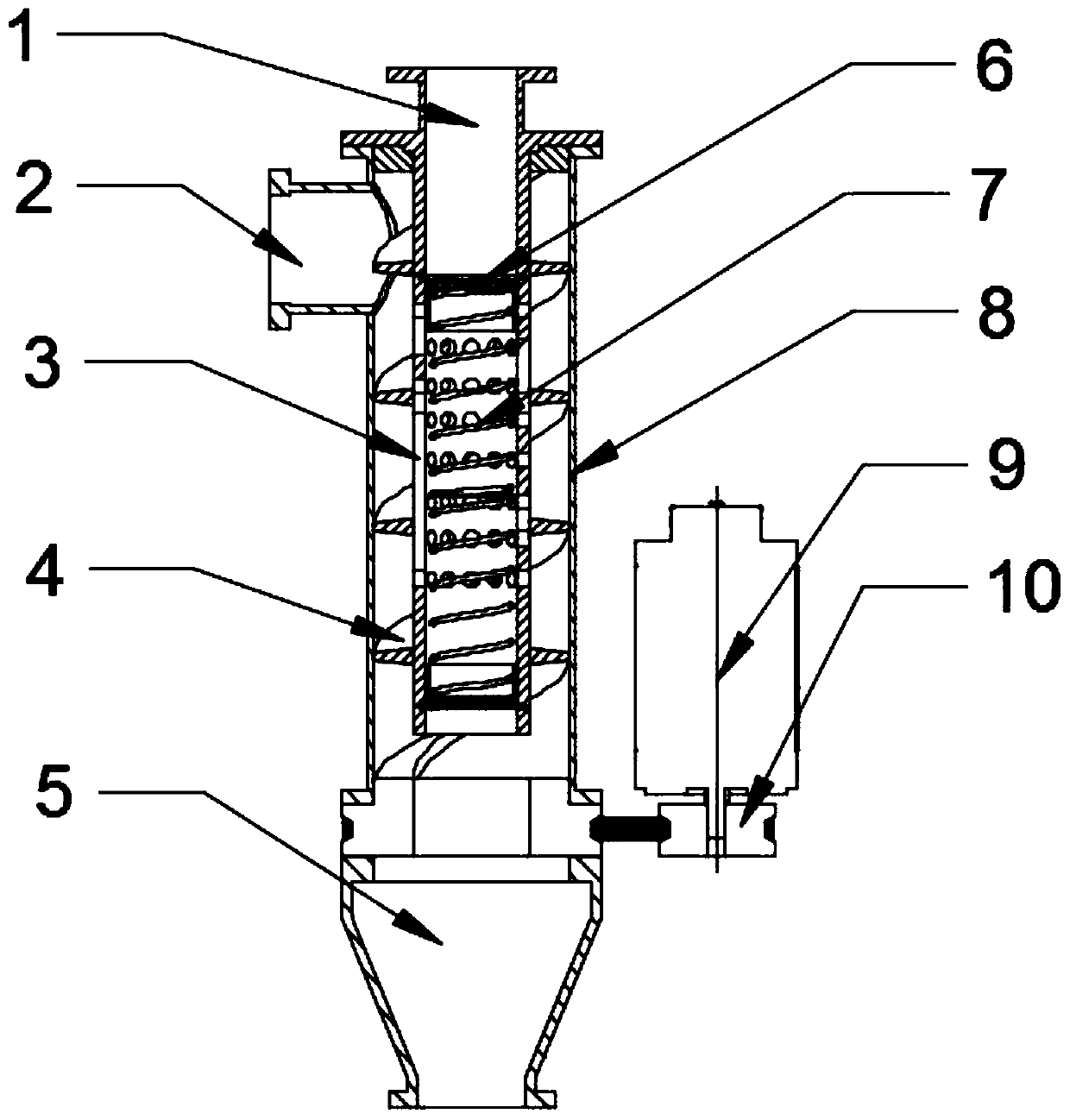

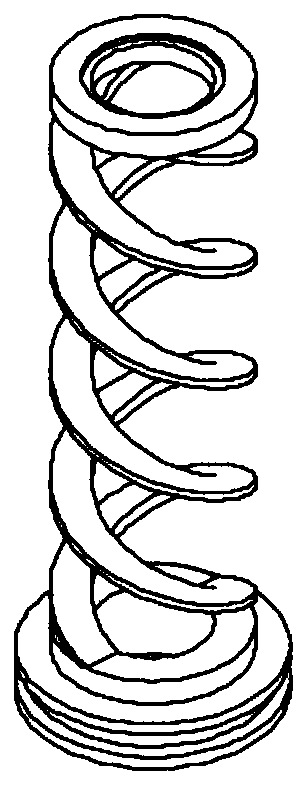

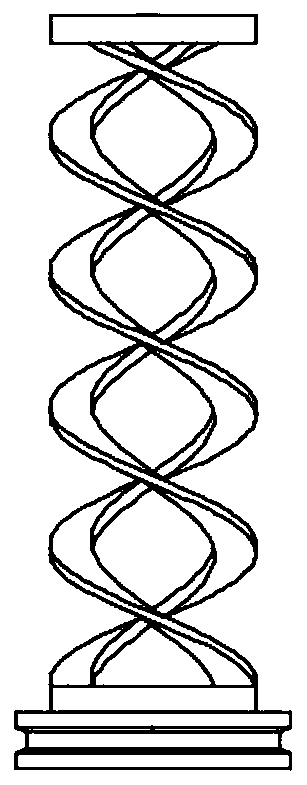

[0030] see Figure 1-Figure 5 , a vertical fast heating device for Antarctic krill, comprising a porous steam introduction pipe 3, in which a spring 7 is arranged; the lower end of the spring 7 is fixed inside the porous steam introduction pipe 3, and the upper end can be compressed downwards, and is connected with the steam volume control cap 6 Fixed connection, sealing and sliding between the steam volume control cap 6 and the inner wall of the porous steam introduction pipe 3, there is a hole on the upper end of the steam volume control cap with a circlip to limit the highest position of the steam volume control cap; different heights on the side walls of the porous steam introduction pipe 3 Open multiple groups of through holes; the porous steam introduction pipe 3 is arranged inside the shell 8, and the vertical spiral scraper 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com