Method of comprehensively utilizing aluminum dross to prepare anti-oxidation coating for carbon anode used for electrolytic aluminum

An anti-oxidation coating and electrolytic aluminum technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of land occupation, water and soil pollution, etc., achieve the effects of reducing difficulty, realizing waste utilization, and solving the problems of aluminum ash storage yards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

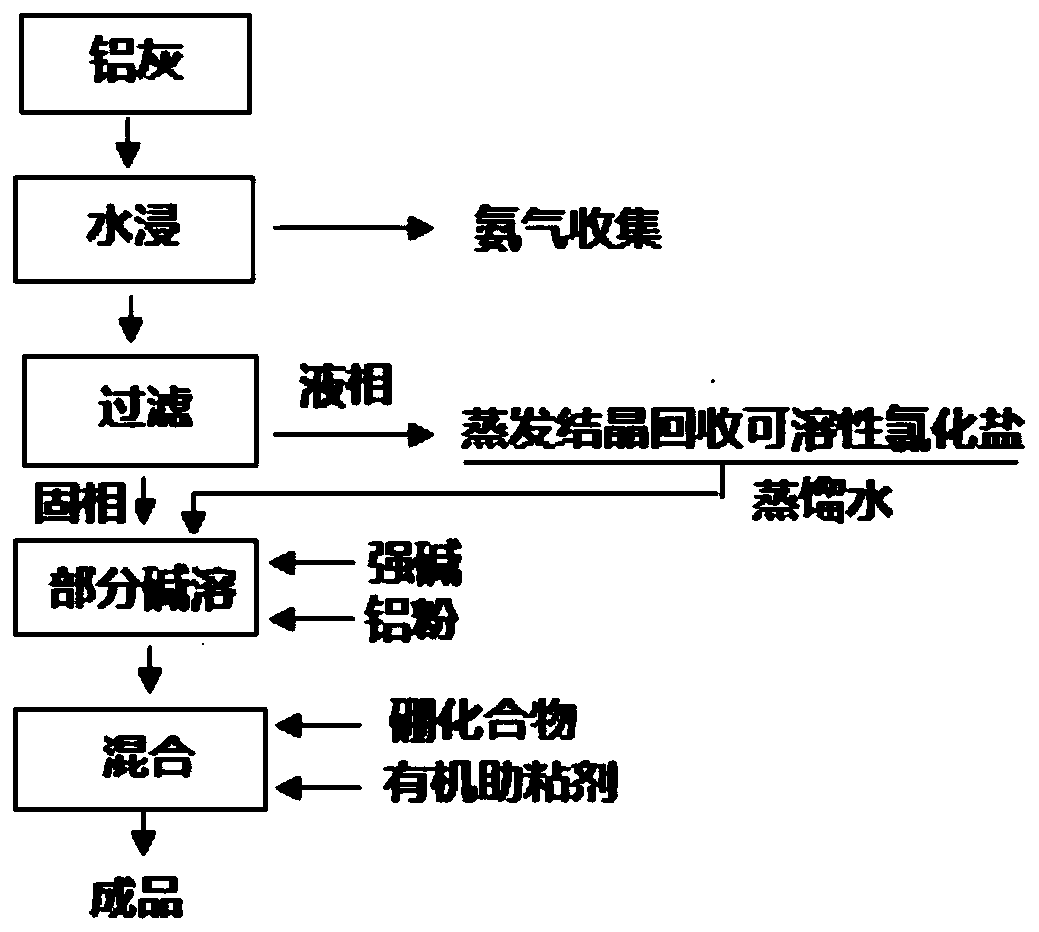

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of carbon anode coating for electrolytic aluminum

[0050] 1) Accurately weigh the raw materials according to the following ratio:

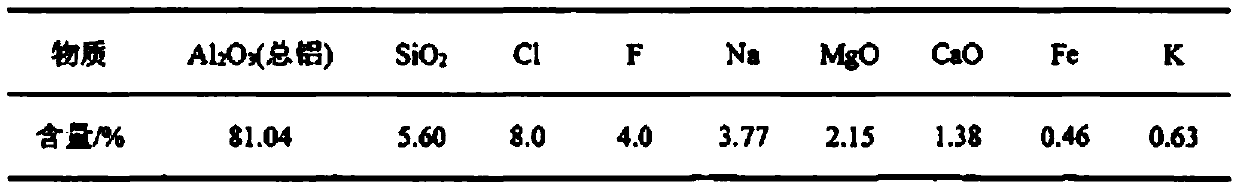

[0051] 20 parts of aluminum ash, 5 parts of sodium hydroxide, 1 part of industrial aluminum powder, 1 part of sodium borate, 1 part of carboxymethyl cellulose, and 15 parts of water produced in the electrolytic aluminum process; the aluminum ash comes from an electrolytic The aluminum ash slag produced in the aluminum factory is obtained by grinding it through a 200-mesh sieve;

[0052] 2) Add the aluminum ash to the water, keep it warm at 75°C for 3 hours under stirring conditions, until no more ammonia gas is generated; during this period, the ammonia gas is collected; this step is the water immersion process of the aluminum ash, and the main purpose is to nitride Aluminum is converted to alumina;

[0053] 3) cooling the liquid material produced in step 2) to room temperature, filtering, moving the filtrate into ...

Embodiment 2

[0057] Embodiment 2: Preparation of carbon anode coating for electrolytic aluminum

[0058] 1) Accurately weigh the raw materials according to the following ratio:

[0059] 50 parts of aluminum ash, 10 parts of sodium hydroxide, 3 parts of industrial aluminum powder, 2 parts of sodium borate, 1 part of carboxymethyl cellulose, and 15 parts of water produced in the electrolytic aluminum process; the aluminum ash comes from an electrolysis plant in Binzhou City, Shandong Province The aluminum ash slag produced in the aluminum factory is obtained by grinding it through a 200-mesh sieve;

[0060] 2) Add the aluminum ash to the water, keep it warm at 100°C for 5 hours under stirring conditions, until no more ammonia gas is generated; during this period, the ammonia gas is collected; this step is the water immersion process of the aluminum ash, and the main purpose is to nitride Aluminum is converted to alumina;

[0061] 3) cooling the liquid material produced in step 2) to room t...

Embodiment 3

[0065] Embodiment 3: Preparation of carbon anode coating for electrolytic aluminum

[0066] 1) Accurately weigh the raw materials according to the following ratio:

[0067] 45 parts of aluminum ash, 15 parts of sodium hydroxide, 5 parts of industrial aluminum powder, 1 part of sodium borate, 3 parts of carboxymethyl cellulose, and 50 parts of water produced in the electrolytic aluminum process; the aluminum ash comes from an electrolytic company in Binzhou City, Shandong Province The aluminum ash slag produced in the aluminum factory is obtained by grinding it through a 200-mesh sieve;

[0068] 2) Add the aluminum ash to the water, keep it warm at 80°C for 10 hours under stirring conditions, until no more ammonia gas is produced; during this period, the ammonia gas is collected; this step is the water immersion process of the aluminum ash, and the main purpose is to nitride Aluminum is converted to alumina;

[0069] 3) cooling the liquid material produced in step 2) to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com