Irradiation cross-linked insulating polyethylene master batch capable of resisting UVLED light attenuation and preparation method and application thereof

A technology of cross-linked polyethylene and polyethylene resin, which is applied in the field of ultraviolet light cross-linked polyethylene insulation materials, can solve the problems of light decay of UV LED lamp bead light source, insufficient cross-linking degree of cable insulation layer, and increased cost of artificial water and electricity. The effect of delaying the light decay speed, fast cross-linking speed and uniform cross-linking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

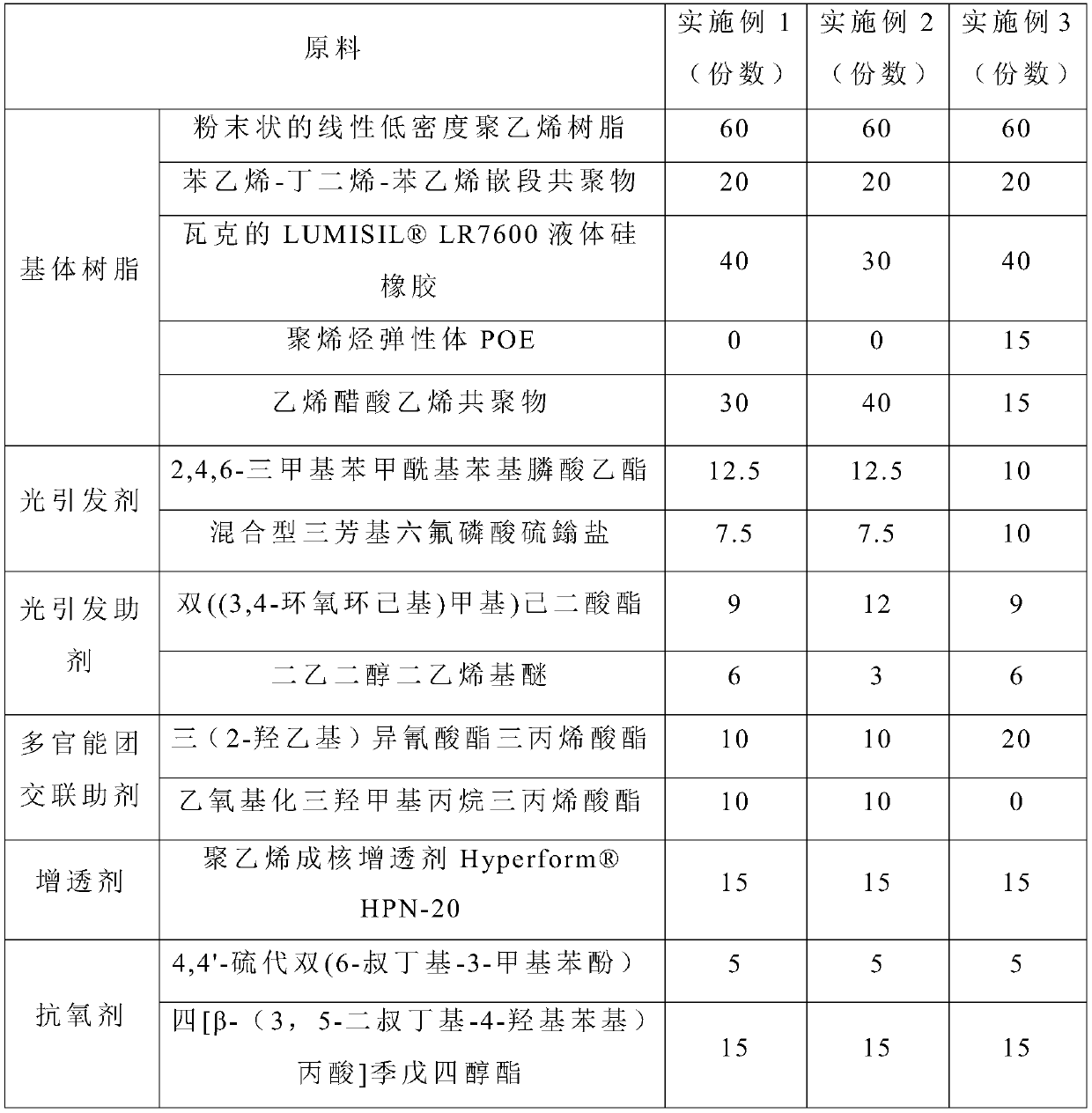

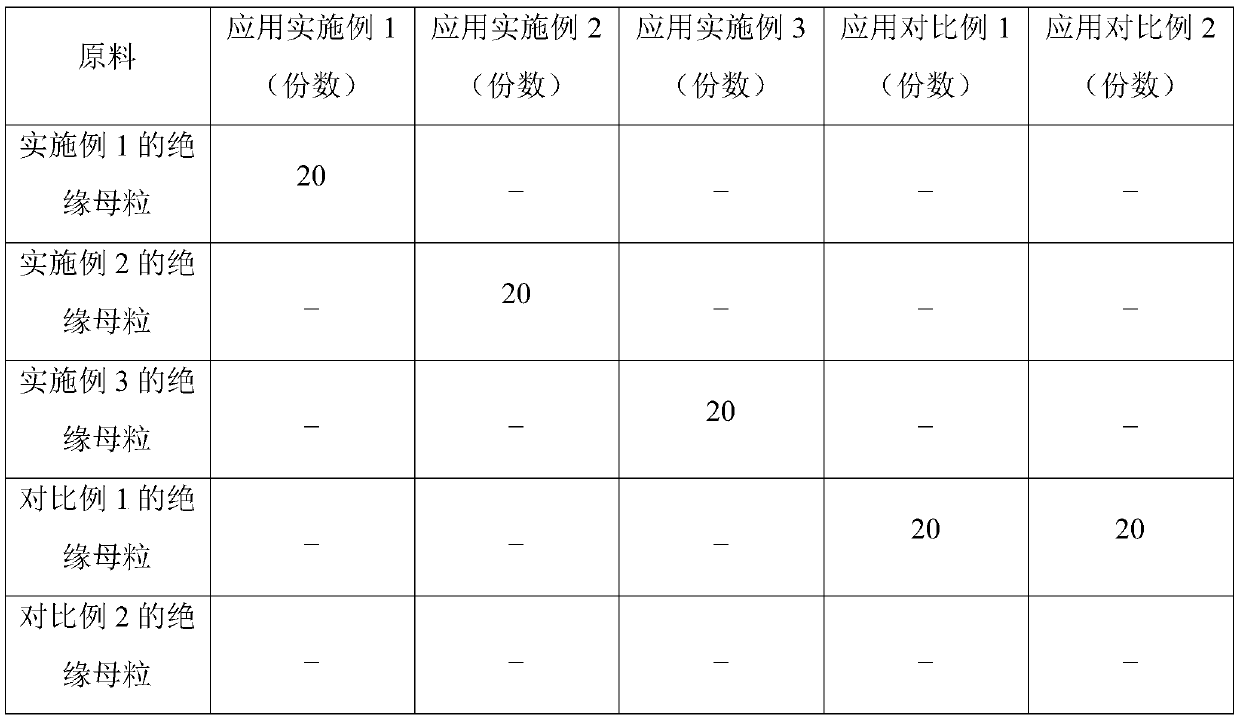

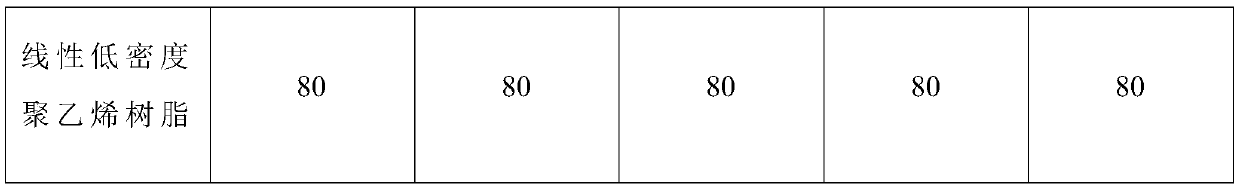

[0046] These embodiments provide an anti-UVLED light attenuation irradiation cross-linked polyethylene insulating masterbatch, the raw material composition and dosage of which are shown in Table 1 below.

[0047] Table 1

[0048]

[0049] The preparation method comprises the following steps:

[0050] Weigh each raw material according to the formula, stir and mix linear low density polyethylene resin, styrene-butadiene-styrene block copolymer, photoinitiator, photoinitiation aid and multifunctional crosslinking aid to prepare premix material, and then mix the premixed material with the remaining raw materials and extrude;

[0051] The extrusion molding conditions are as follows: the extrusion temperature is 155±2°C, and the die temperature is 165°C. In the extrusion process, UV LED is used for normal lighting, and the condition is: the pearl light intensity of a single lamp is 950-1000mW / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com