Biomass double fluidized bed catalytic gasification combined cycle power generation method using copper slag as circulating bed material and system thereof

A combined cycle power generation and fluidized bed gasifier technology, applied in the fields of energy and environment, can solve the problems of adverse effects of double fluidized bed operation, low mechanical strength of dolomite, and large amount of dolomite, and achieve good economic and environmental benefits. , low cost, the effect of reducing the content of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

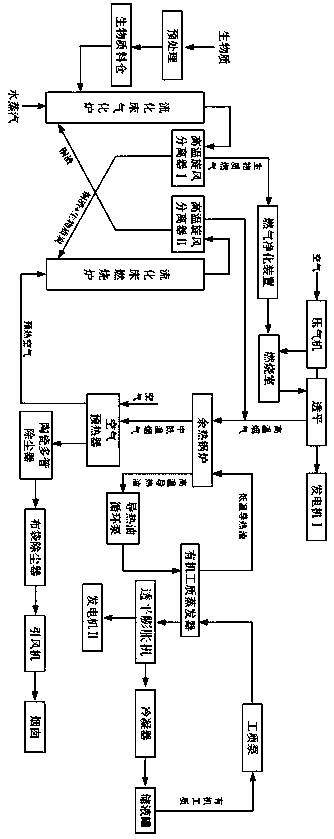

[0028] Embodiment 1: as figure 1 As shown, the biomass double fluidized bed catalytic gasification combined cycle power generation method using copper slag as circulating bed material is as follows:

[0029] (1) The pine wood leftovers are crushed, dried and pretreated, and then enter the biomass silo. The biomass in the silo is sent to the fluidized bed gasifier through the feeding device, and the steam that is used as the fluidized medium and participates in the gasification reaction is discharged from the fluidized bed. The bottom of the gasifier is fed into the gasifier, and the biomass raw material undergoes pyrolysis and gasification under the heating of the high-temperature copper slag of the circulating bed material to generate biomass gas, biomass charcoal and tar. The circulating bed material is made of Noranda smelting slag in the Calcined copper slag calcined at 950°C for 6 hours in an air atmosphere; the particle size of the copper slag is 1.2 mm; the temperature ...

Embodiment 2

[0036] Embodiment 2: The biomass dual fluidized bed catalytic gasification combined cycle power generation method using copper slag as circulating bed material is as follows:

[0037] (1) The walnut shells enter the biomass silo after crushing, drying and pretreatment, and the biomass in the silo is sent to the fluidized bed gasifier through the feeding device, as a fluidization medium and participates in the steam-air mixture of the gasification reaction The gas is fed from the bottom of the fluidized bed gasifier, and the biomass raw material undergoes pyrolysis and gasification reaction under the heating of the high-temperature copper slag of the circulating bed material to generate biomass gas, biomass charcoal and tar. The copper slag is made of Oss Matt smelting slag; the particle size of copper slag is 1.5mm; the temperature in the fluidized bed gasifier is 900°C, and the tar undergoes a catalytic cracking reaction under the action of the copper slag bed material, and th...

Embodiment 3

[0044] Embodiment 3: The biomass double fluidized bed catalytic gasification combined cycle power generation method using copper slag as circulating bed material is as follows:

[0045] (1) The corn stalks enter the biomass silo after crushing, drying and pretreatment, and the biomass in the silo is sent to the fluidized bed gasifier through the feeding device, as a fluidization medium and participates in the steam-air mixing of the gasification reaction The gas is fed from the bottom of the fluidized bed gasifier, and the biomass raw material undergoes pyrolysis and gasification reaction under the heating of the high-temperature copper slag of the circulating bed material to generate biomass gas, biomass charcoal and tar, which are smelted by Noranda Copper slag mixed with Vanyukov smelting slag at a mass ratio of 1:1, and then in H 2 Reduction under atmosphere for 5 hours, the particle size of copper slag is 2.0mm; the temperature in the fluidized bed gasifier is 800°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com