Preparation method of agricultural plastic bowl soft tray material with aging resistance and wear resistance

A plastic bowl and anti-aging technology is applied in the field of preparation of agricultural anti-aging and anti-wear plastic bowl floppy disk materials, which can solve the problems of wear resistance, reduced processing temperature, long residual time, etc., and achieves a simple modification treatment method and reduces The use of plasticizers, the effect of improving hydrophobicity and lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

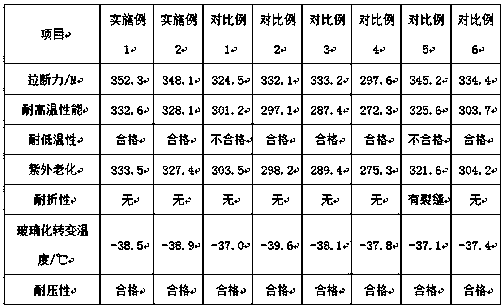

Image

Examples

Embodiment 1

[0017] A method for preparing an agricultural aging-resistant and wear-resistant plastic bowl floppy disk material, comprising the following steps:

[0018]1. Add 113 parts of soybean oil, 22.3 parts of glyceryl triacetate and 0.9 part of dibutyltin maleate to the reaction kettle equipped with a stirring device, a thermometer and a reflux condensing tube in sequence, feed nitrogen and stir to raise the temperature. When the temperature reaches At 140°C, add 22.4 parts of sodium hydroxide, insulate and stir the reaction at 200°C for 2 hours, and end the reaction to obtain a champagne yellow product; Device, thermometer, dropping funnel, reflux condensing tube in the reaction kettle, the temperature was raised to 55°C under stirring, and 23 parts of hydrogen peroxide with a volume fraction of 25% and 0.7 parts of concentrated sulfuric acid with a mass fraction of 98% were slowly added dropwise under stirring. React at 80°C for 4 hours, separate the lower layer of acid water, was...

Embodiment 2

[0025] A method for preparing an agricultural aging-resistant and wear-resistant plastic bowl floppy disk material, comprising the following steps:

[0026] 1. Add 100 parts of soybean oil, 20.2 parts of glyceryl triacetate, and 0.5 parts of dibutyltin maleate into the reaction kettle equipped with a stirring device, a thermometer, and a reflux condenser in sequence, and feed in nitrogen gas and stir to raise the temperature. When the temperature reaches At 130°C, add 2.1 parts of sodium hydroxide, insulate and stir the reaction at 180°C for 1 hour, and end the reaction to obtain a champagne yellow product; Device, thermometer, dropping funnel, and reflux condenser in the reaction kettle, the temperature was raised to 50°C under stirring, and 10 parts of hydrogen peroxide with a volume fraction of 20% and 0.5 parts of concentrated sulfuric acid with a mass fraction of 98% were slowly added dropwise under stirring. React at 75°C for 3 hours, separate the lower layer of acid wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com