Preparation method of dendrobium instant freeze-dried blocks

A dendrobium and instant technology, which is applied in the direction of freeze-dried transportation, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of less dissolution of active ingredients, influence on taking, and easy to stick into agglomerates, etc. Achieve broad market application prospects, low residual moisture, excellent resolubility and instant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

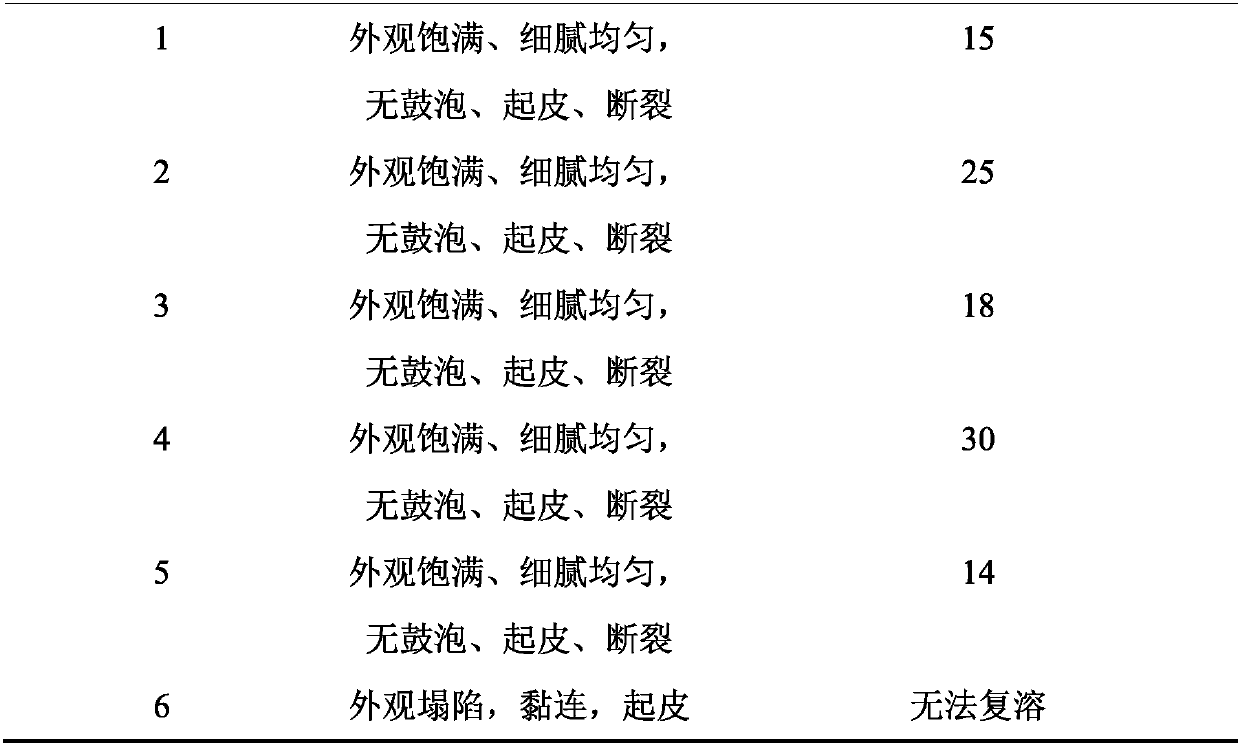

Examples

Embodiment 1

[0030] (1) Remove the leaves of the fresh dendrobium raw material, wash and cut into 1-2cm segments;

[0031] (2) Place the above-mentioned small section in a wall-breaking device, mix it with 10 times the volume of distilled water, and break the wall at a speed of 30,000 rpm for 1 min;

[0032] (3) The material obtained in step (2) is filtered by a three-legged centrifugal filter, and its rotating speed is 500~800rpm;

[0033] (4) Place the solid obtained in step (3) in a high-speed dispersion device, and disperse for 3 minutes at a speed of 8000 rpm;

[0034] (5) The material obtained in step (4) is placed in a high-pressure homogenization device for high-pressure homogenization twice, and each high-pressure homogenization includes the first homogenization and the second homogenization successively, wherein the pressure of the first homogenization 400Bar, the second homogeneous pressure is 1500Bar;

[0035] (6) add 5wt% lactose in the material of step (5) gained;

[0036]...

Embodiment 2

[0042] (1) Remove the leaves of the fresh dendrobium raw material, wash and cut into 1-2cm segments;

[0043](2) Place the above-mentioned small section in a wall-breaking device, mix it with 10 times the volume of distilled water, and break the wall at a speed of 30,000 rpm for 1 min;

[0044] (3) The material obtained in step (2) is filtered by a three-legged centrifugal filter, and its rotating speed is 500~800rpm;

[0045] (4) Place the solid obtained in step (3) in a high-speed dispersion device, and disperse for 3 minutes at a speed of 8000 rpm;

[0046] (5) The material obtained in step (4) is placed in a high-pressure homogenization device for high-pressure homogenization twice, and each high-pressure homogenization includes the first homogenization and the second homogenization successively, wherein the pressure of the first homogenization 400Bar, the second homogeneous pressure is 1500Bar;

[0047] (6) add 5wt% sucrose in the material of step (5) gained;

[0048] ...

Embodiment 3

[0054] (1) Remove the leaves of the fresh dendrobium raw material, wash and cut into 1-2cm segments;

[0055] (2) Place the above-mentioned small section in a wall-breaking device, mix it with 10 times the volume of distilled water, and break the wall at a speed of 30,000 rpm for 1 min;

[0056] (3) The material obtained in step (2) is filtered by a three-legged centrifugal filter, and its rotating speed is 500~800rpm;

[0057] (4) Place the solid obtained in step (3) in a high-speed dispersion device, and disperse for 3 minutes at a speed of 8000 rpm;

[0058] (5) The material obtained in step (4) is placed in a high-pressure homogenization device for high-pressure homogenization twice, and each high-pressure homogenization includes the first homogenization and the second homogenization successively, wherein the pressure of the first homogenization 400Bar, the second homogeneous pressure is 1500Bar;

[0059] (6) adding 5wt% glucose to the material obtained in step (5);

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com