Method of increasing yield of L-isoleucine

A technology of isoleucine and yield, which is applied in the field of increasing the yield of L-isoleucine, can solve the problems of long fermentation period, low acid production rate, low product quality, etc., and achieve increased yield, easy operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for increasing the output of L-isoleucine, comprising the steps of:

[0030] Using Corynebacterium glutamicum ATCC14309 as the experimental strain, Corynebacterium glutamicum seed solution (OD 600 The value is 12) According to the inoculation amount of 6%, transfer to a 50L fermenter containing 30L fermentation medium for cultivation, the temperature is 30°C, the cultivation time is 60 hours, and the pH of the medium is controlled by automatically adding 20% ammonia water to 6.8-7.0. Control the dissolved oxygen at 25% by stirring and ventilating, add glucose nutrient solution, and control the residual sugar content in the fermentation broth to not be less than 1g / L;

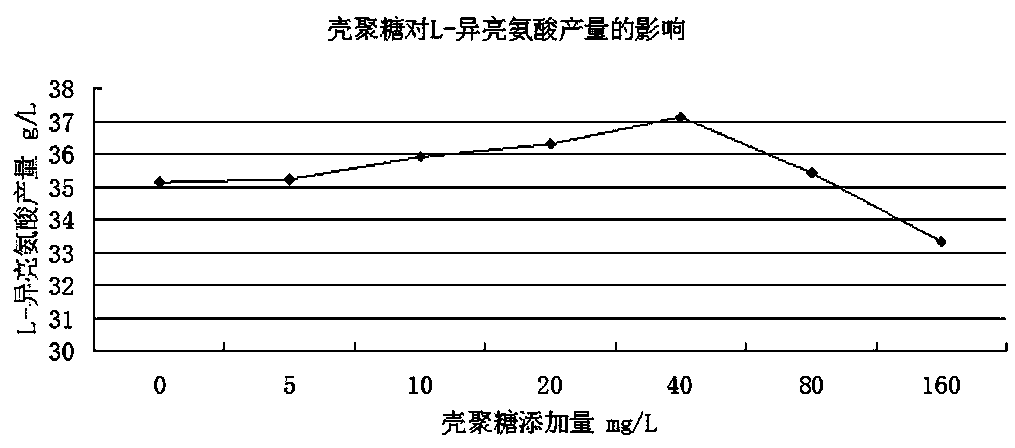

[0031] During the fermentation process, 0.2 L of H 2 o 2 ; In the time of 48h, add chitosan in fermenter, control the concentration of chitosan to be 40mg / L;

[0032] The fermentation medium component is: glucose 80g / L, (NH 4 ) 2 SO 4 20g / L, corn steep liquor 10g / L, KH 2 PO 4 5g / L, Mg...

Embodiment 2

[0035] A method for increasing the output of L-isoleucine, comprising the steps of:

[0036] Using Corynebacterium glutamicum ATCC14309 as the experimental strain, Corynebacterium glutamicum seed solution (OD 600 The value is 11) According to the inoculum amount of 7%, it is transferred to a 50L fermenter containing 30L fermentation medium for cultivation, the temperature is 30°C, the cultivation time is 60 hours, and the pH of the medium is controlled by automatically adding 20% ammonia water to 6.8-7.0. Control the dissolved oxygen at 20% by stirring and ventilating, add glucose nutrient solution, and control the residual sugar content in the fermentation broth to not be less than 1g / L;

[0037] During the fermentation process, 0.15 L of H 2 o 2; In the time of 48h, add chitosan in fermenter, control the concentration of chitosan to be 40mg / L;

[0038] The fermentation medium component is: glucose 80g / L, (NH 4 ) 2 SO 4 20g / L, corn syrup 10g / L, KH 2 PO 4 5g / L, MgS...

Embodiment 3

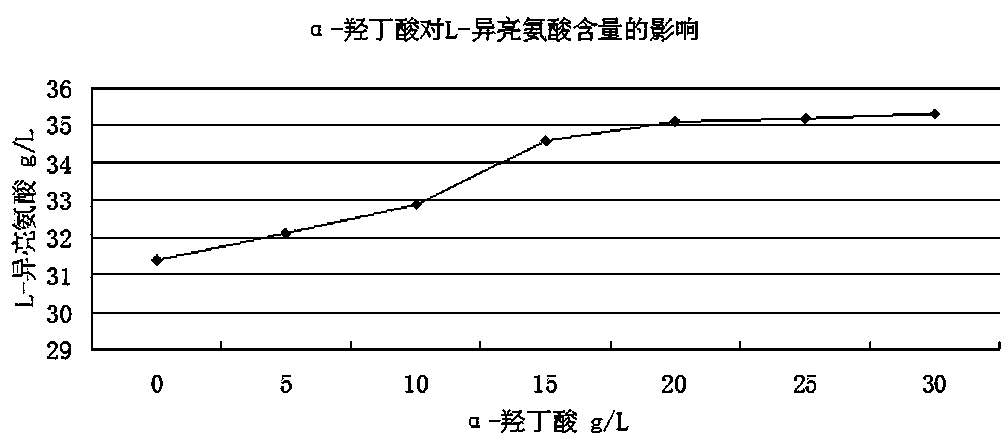

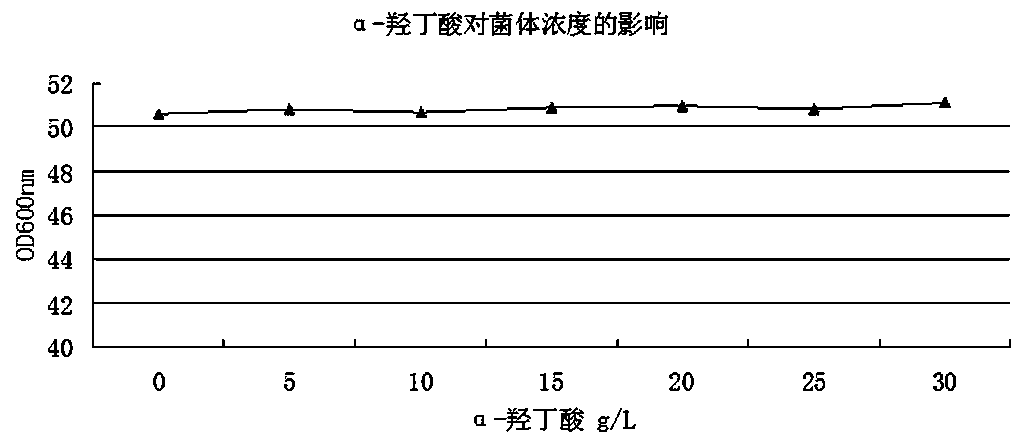

[0055] 1.H 2 o 2 Effects of addition amount and timing on L-isoleucine production and cell biomass in fermentation broth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com