Manufacturing method of environment-friendly pressure-sensitive adhesive material

A production method and pressure-sensitive adhesive technology, applied in the direction of pressure-sensitive films/sheets, adhesives, film/sheet-shaped adhesives, etc., can solve the problems of pressure-sensitive adhesives that cannot be degraded, hidden safety hazards, and toxic waste gas. Achieve the effect of improving resource utilization efficiency, compact production process and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

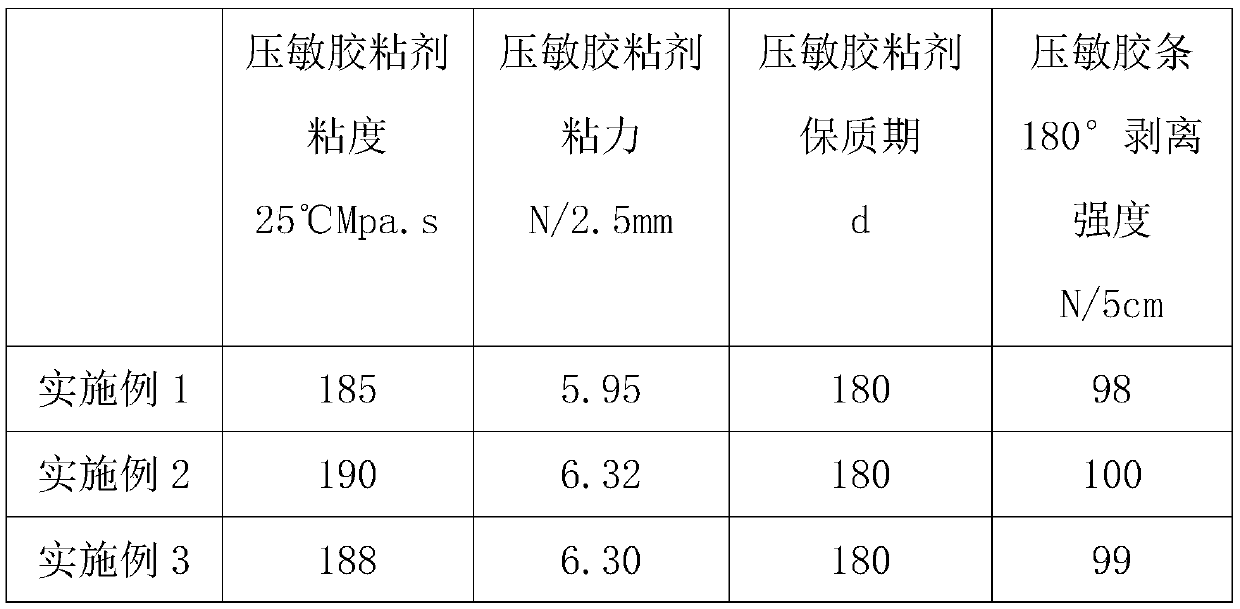

Examples

Embodiment 1

[0027] A method for making an environment-friendly pressure-sensitive adhesive material, comprising a pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer is composed of a base material, a pressure-sensitive adhesive and a release paper, one side of the base material is provided with a pressure-sensitive adhesive, the A release paper is provided on the side of the pressure-sensitive adhesive away from the substrate, a bonding layer is provided between the substrate and the pressure-sensitive adhesive, and a protective layer is provided on the back of the substrate;

[0028] Also includes the preparation method of the pressure-sensitive adhesive material, the specific steps are as follows:

[0029] Step 1: Choose non-woven fabric as the substrate, cut it neatly according to the production specifications, after dust removal, spray polytetrafluoroethylene aqueous solution on one side of the cut substrate, and make a protective layer after air-drying. The other...

Embodiment 2

[0038] A method for making an environment-friendly pressure-sensitive adhesive material, comprising a pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer is composed of a base material, a pressure-sensitive adhesive and a release paper, one side of the base material is provided with a pressure-sensitive adhesive, the A release paper is provided on the side of the pressure-sensitive adhesive away from the substrate, a bonding layer is provided between the substrate and the pressure-sensitive adhesive, and a protective layer is provided on the back of the substrate;

[0039] Also includes the preparation method of the pressure-sensitive adhesive material, the specific steps are as follows:

[0040] Step 1: Choose non-woven fabric as the substrate, cut it neatly according to the production specifications, after dust removal, spray polytetrafluoroethylene aqueous solution on one side of the cut substrate, and make a protective layer after air-drying. The other...

Embodiment 3

[0049] A method for making an environment-friendly pressure-sensitive adhesive material, comprising a pressure-sensitive adhesive layer, the pressure-sensitive adhesive layer is composed of a base material, a pressure-sensitive adhesive and a release paper, one side of the base material is provided with a pressure-sensitive adhesive, the A release paper is provided on the side of the pressure-sensitive adhesive away from the substrate, a bonding layer is provided between the substrate and the pressure-sensitive adhesive, and a protective layer is provided on the back of the substrate;

[0050] Also includes the preparation method of the pressure-sensitive adhesive material, the specific steps are as follows:

[0051] Step 1: Choose non-woven fabric as the substrate, cut it neatly according to the production specifications, after dust removal, spray polytetrafluoroethylene aqueous solution on one side of the cut substrate, and make a protective layer after air-drying. The other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com