Oil filling nozzle with high accuracy of gun tripping during oil filling

An accuracy rate and fuel nozzle technology, which is applied in the field of auto parts, can solve problems such as full fuel, fire, and unsafety, and achieve the effect of weakening the impact and improving the accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

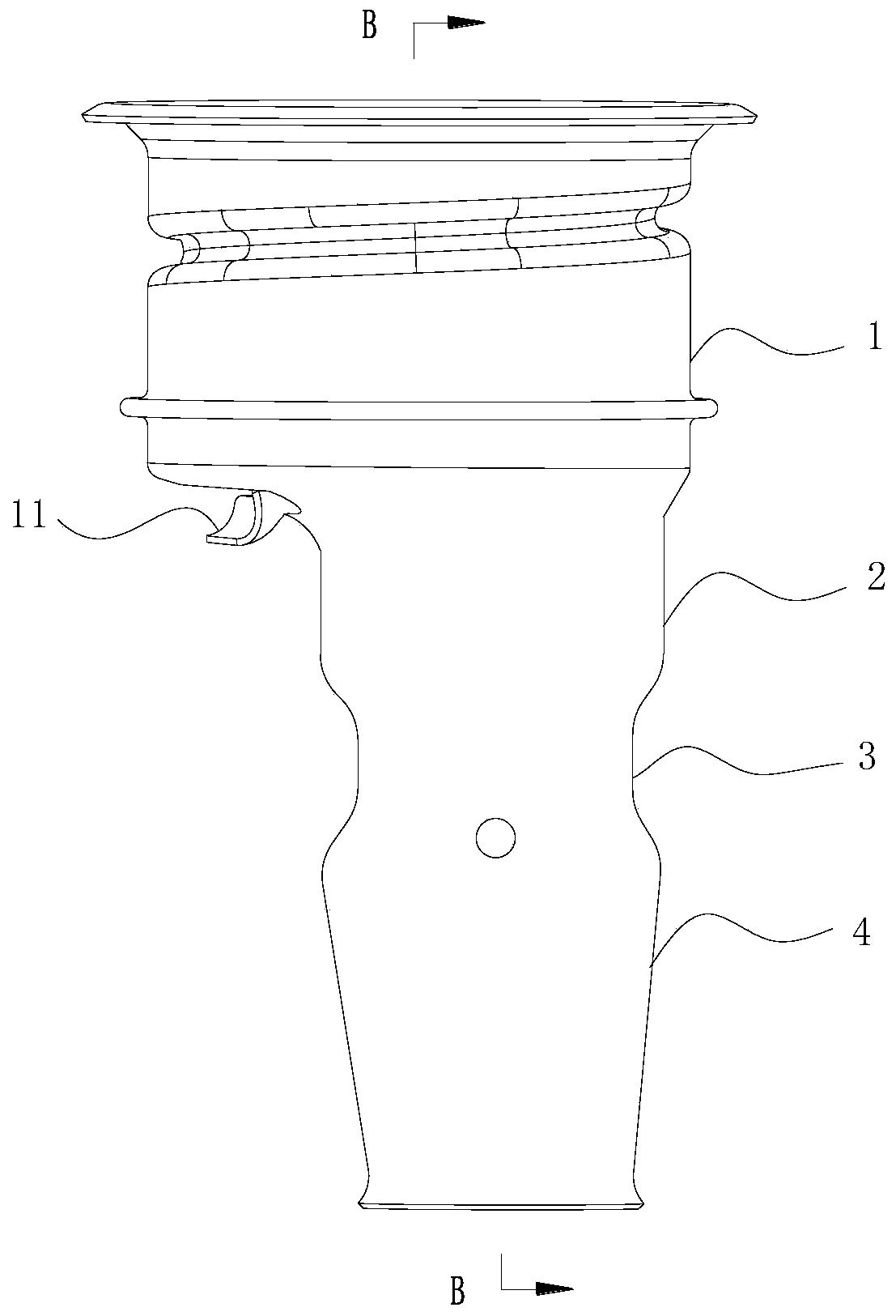

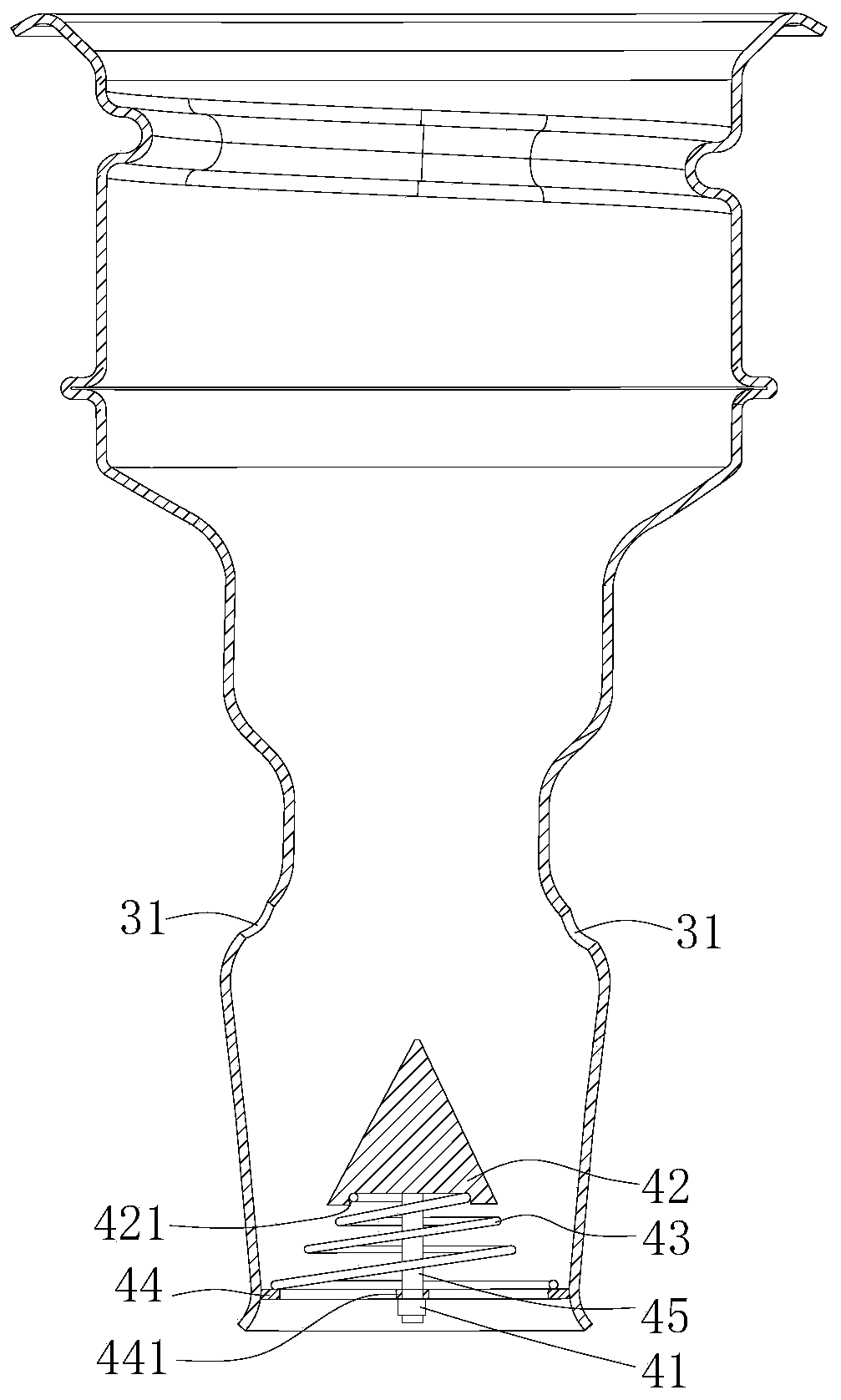

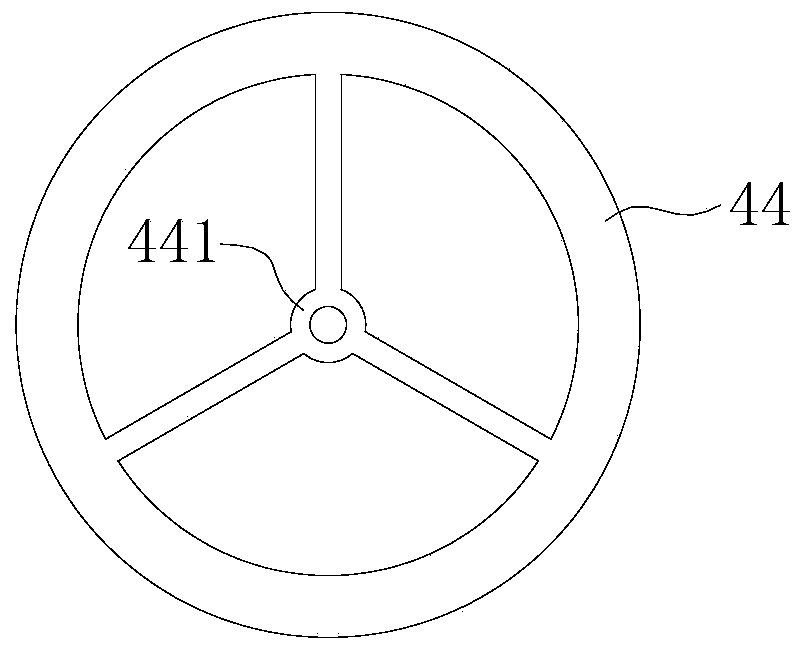

[0019] See Figure 1 to Figure 4 , The fueling nozzle with high accuracy rate of refueling and jumping gun includes a first tube body 1, a second tube body 2 is connected to the bottom of the first tube body 1, and the second tube body 2 is opposite to the first tube body 1 is eccentrically arranged, the bottom of the first tube body 1 is provided with an exhaust window 11; the bottom of the second tube body 2 is connected with a third tube body 3, and the bottom of the third tube body 3 is connected with a fourth tube Tube body 4; the tube wall of the third tube body 3 is recessed inward to form a structure with large ends and small middle ends, and the middle size of the third tube body 3 is adapted to the fuel gun to limit the shaking of the fuel gun, the The lower part of the third pipe body 3 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com