Device for reducing gasification stove synthesis gas water content

A water-carrying and synthetic gas technology, applied in the direction of combined combustion mitigation, combustible gas production, petroleum industry, etc., can solve problems affecting process operation, system load reduction, chilling water level drop, etc., to reduce liquid entrainment and kinetic energy , weaken the impact of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

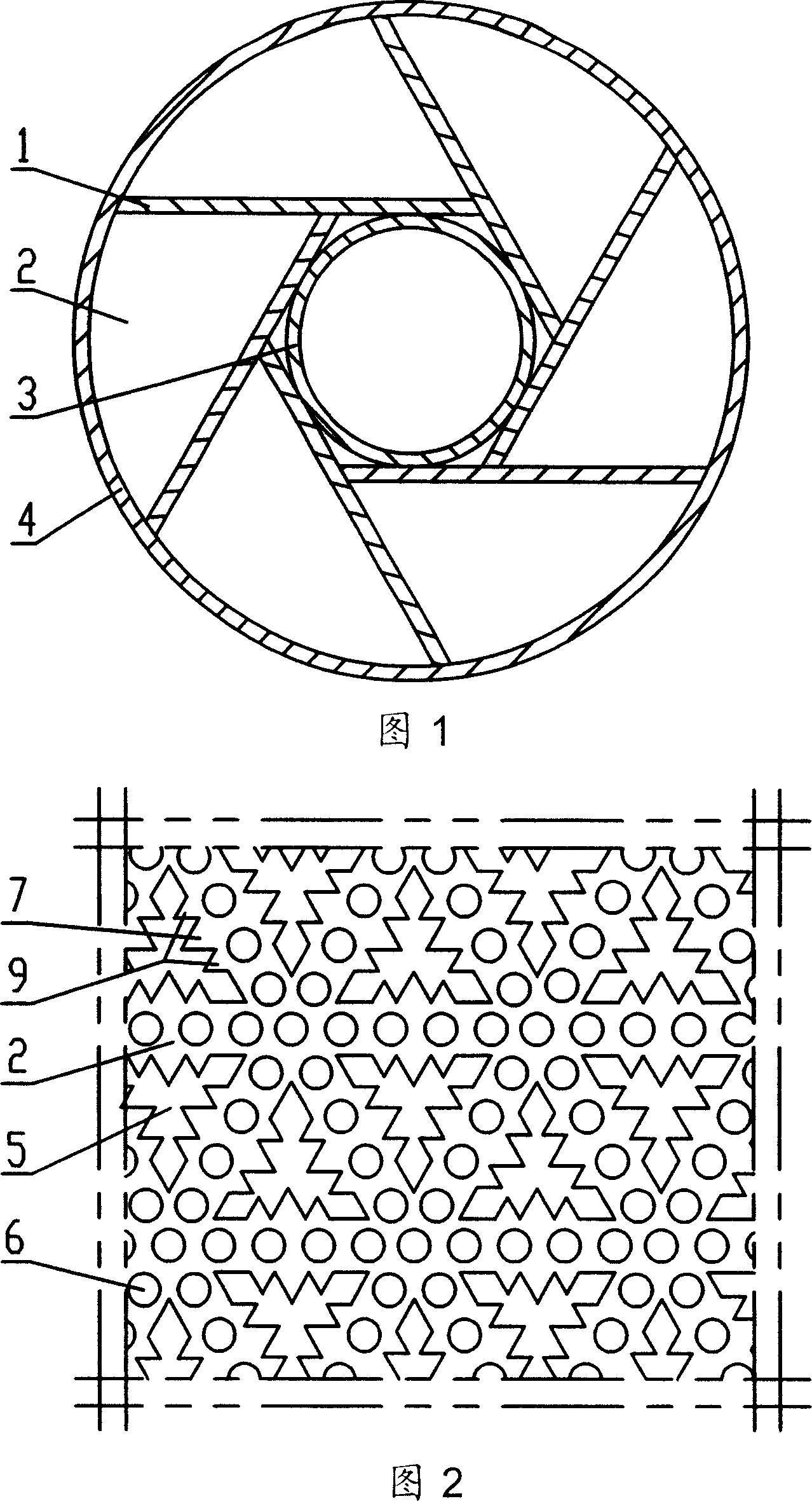

[0015] As shown in Figure 1, the present invention includes: a support plate 1, a water separation baffle plate 2, a downcomer 3 and a furnace shell 4, the support plate 1 is placed horizontally in the annular space between the downcomer 3 and the furnace shell 4, and is fixed Water separation baffle action. The two sides of the support plate 1 are respectively fixed with the downcomer 3 and the furnace shell 4, the inner side of the support plate 1 is welded on the downcomer 3, the outer side is welded on the shell 4, and the water separation baffle 2 is fixed on the support plate 1 to support The plate 1 and the water separation baffle 2 are respectively 3-6 layers.

[0016] As shown in Figure 1, the support plate 1 is an annular flat plate formed by welding together 4-8 metal plates (metal plates such as steel plates, stainless diamond plates, and iron plates), and the angle of each metal plate is 360 degrees / ( 4-8) block arrangement, in this embodiment, 6 steel plates are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com