Double-lock type stitch sewing machine with rotation-proofing device for bobbin case

A sewing machine, double-lock technology, applied in the direction of sewing machine components, sewing machine ring mechanism, sewing equipment, etc., can solve the problem of the device that cannot see the bobbin case reversed, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

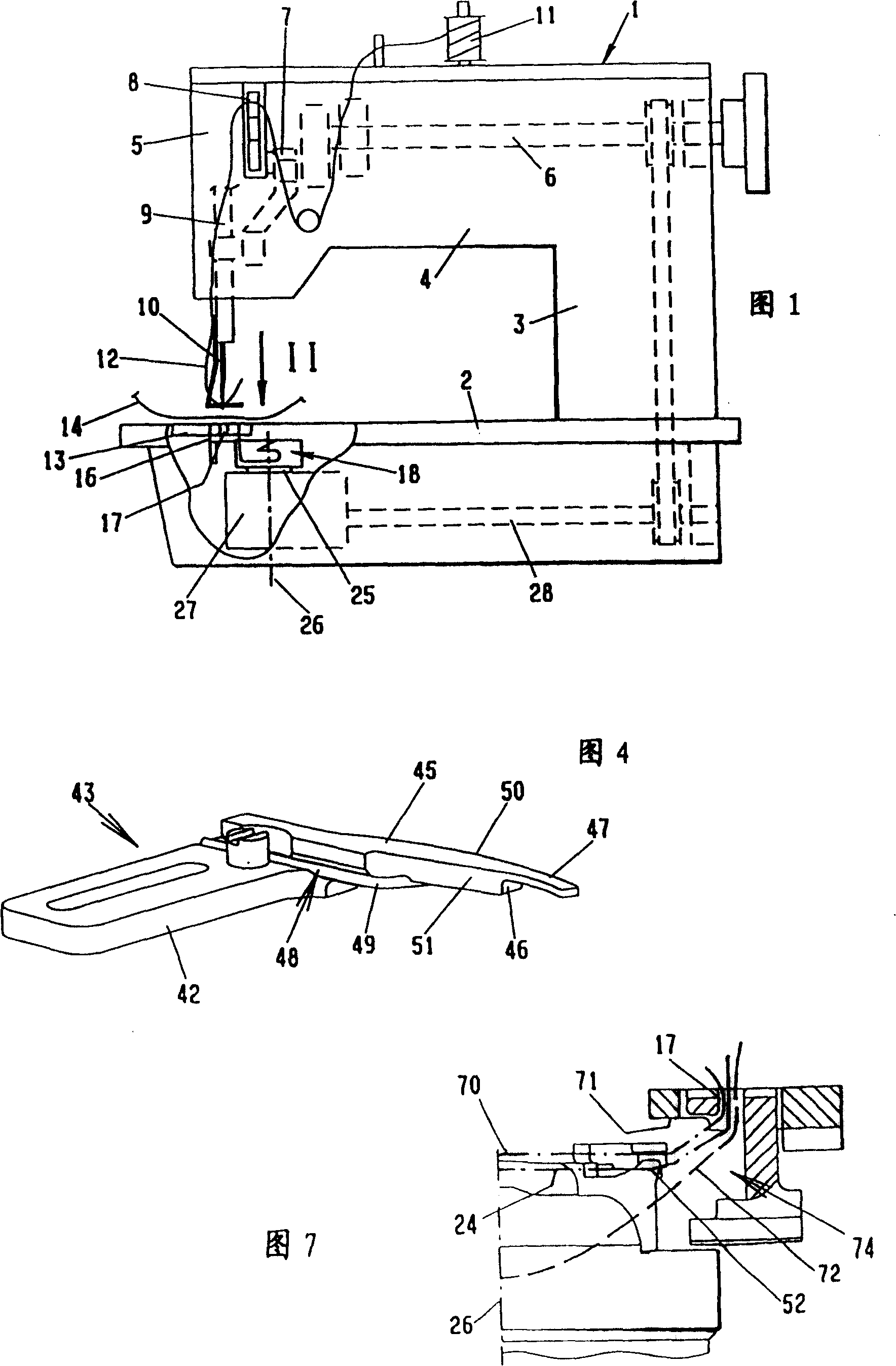

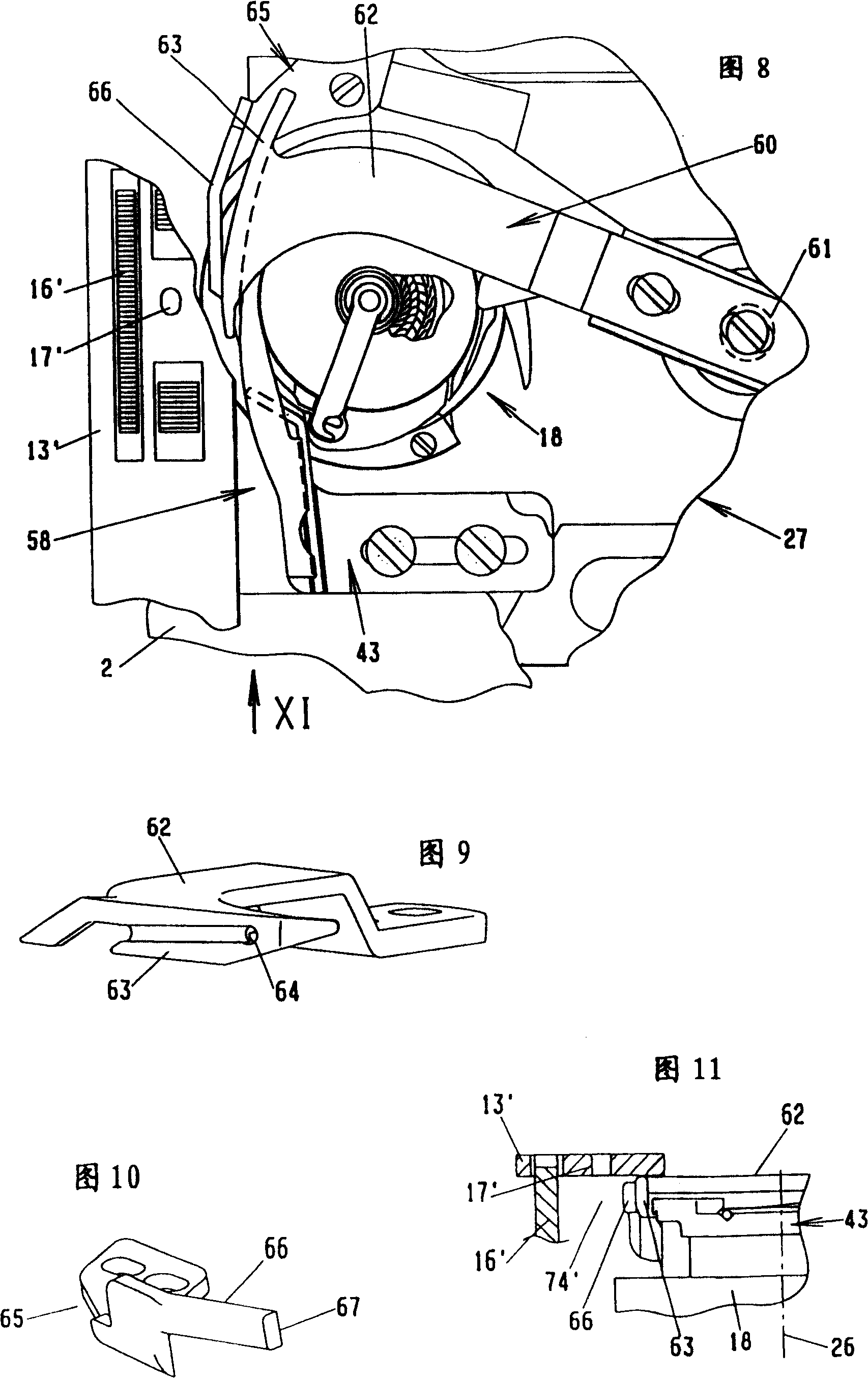

[0039] The sewing machine 1 has a base plate 2 with an upright 3 extending upwardly therefrom and a right-angled arm 4 terminating in a machine head 5 . Mounted rotatably in the arm 4 is an arm shaft 6 , which drives a crank drive 7 with a thread take-up lever 8 in the machine head 5 . The crank drive mechanism 7 is in transmission connection with a needle bar 9 which is movably supported in the machine head 5 and which has a needle 10 at its lower end. Therefore, the needle 10 can be driven by the crank mechanism 7 to move up and down on a vertical axis. The needle 10 guides in the eye of the needle the thread conveyed from the loop 11 through the thread tensioner and the thread take-up lever 8, which is referred to below as sewing thread 12.

[0040] On the base plate 2, there is a panel 13 fixed by screws, on which a sewing product 14 is placed. The panel 13 is made with an opening 15 for a cloth pusher 16 having a needle hole 17 for the passage of a needle 10 . The push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com