A kind of anti-myopia paper and preparation method thereof

A technology of myopia paper and dyeing solution, which is applied in the field of papermaking technology, can solve the problems of poor dispersibility of solid dyes, spot coloring of anti-myopia paper, uneven dyeing, etc., and achieve the effects of reducing visual fatigue, less human eye irritation, and uniform coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

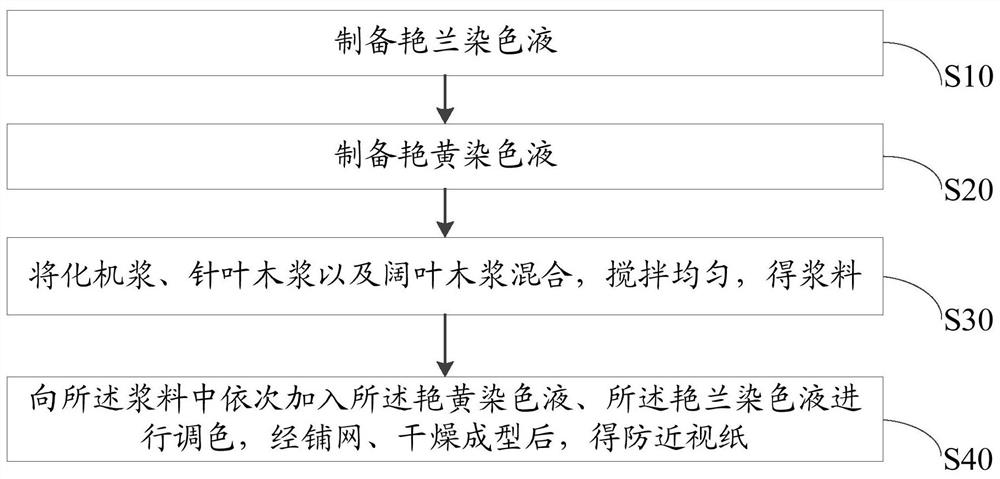

Method used

Image

Examples

preparation example Construction

[0032] In the current preparation process of anti-myopia paper, solid dyes are usually directly put into or dissolved in solid dyes for toning, but solid dyes often have poor dispersibility, resulting in the problem of uneven dyeing, especially when feeding in large quantities. Out of the anti-myopia paper often appear spots or uneven coloring.

[0033] In view of this, the present invention proposes a kind of anti-myopia paper, and described anti-myopia paper comprises slurry, brilliant yellow dyeing liquid and brilliant blue dyeing liquid, wherein, the volume ratio of described brilliant yellow dyeing liquid and described brilliant blue dyeing liquid is (19.5~20.5): 1; the bright yellow staining solution comprises the following raw materials: 15~30 (v / v)% hydrochloric acid solution, 1-amino-4-sulfonic acid-6-acetylamino-naphthalene, sodium folinate and Barbituric acid; the Brilliant Blue staining solution includes the following raw materials: blue matrix, acetic acid and wat...

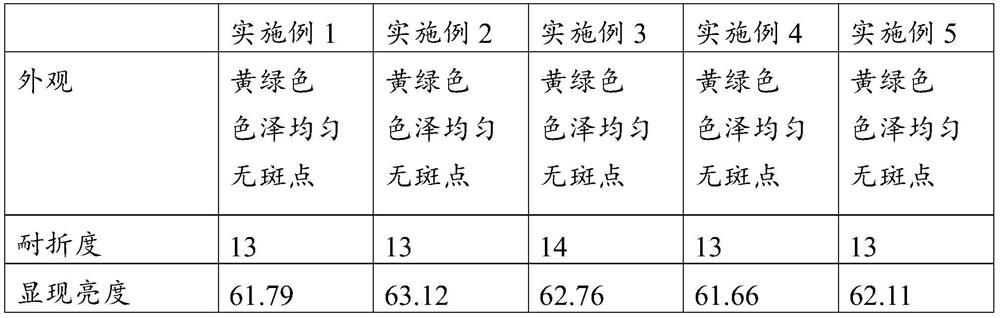

Embodiment 1

[0058] Add acetic acid and water to the blue matrix, heat to 50°C, and stir until dissolved. When no particles are detected, collect the brilliant blue stock solution and adjust the pH to 1.0. Add water to dilute it into a brilliant blue staining solution with a mass concentration of 15%. ,spare.

[0059] After dissolving 1-amino-4-sulfonic acid-6-acetylamino-naphthalene (1mol) in water, add 15 (v / v)% hydrochloric acid solution (containing HCL1mol), and stir until 1-amino-4-sulfonic acid- After the 6-acetylamino-naphthalene is completely dissolved, add sodium folinate solution at 5°C, and test the solution with starch potassium iodide test paper to keep the test paper slightly blue. The diazotization reaction is for 3 hours, and the diazonium salt solution is obtained after the reaction is completed; Pressure filter the diazonium salt solution, discard the filtrate, and keep the filter cake; add barbituric acid to the filter cake and adjust the pH to 7.0-7.5, and perform a cou...

Embodiment 2

[0064] Add acetic acid and water to the blue matrix, heat to 40°C, and stir until dissolved. When no particles are detected, collect the brilliant blue stock solution and adjust the pH to 2.0, add water to dilute it into a brilliant blue staining solution with a mass concentration of 12%. ,spare.

[0065] After dissolving 1-amino-4-sulfonic acid-6-acetylamino-naphthalene (1mol) in water, add 30 (v / v)% hydrochloric acid solution (containing HCL1.2mol), and stir until 1-amino-4-sulfonic acid After acid-6-acetylamino-naphthalene is completely dissolved, add sodium folinate solution at 5°C, and test the solution with starch potassium iodide test paper to keep the test paper slightly blue. The diazotization reaction is 3 hours, and the diazonium salt is obtained after the reaction is completed. solution; press filter the diazonium salt solution, discard the filtrate, and keep the filter cake; add barbituric acid to the filter cake and adjust the pH to 7.0-7.5, and perform a couplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com