A polyamide-imide-polyimide copolymer molding compound and its preparation method

A technology of polyamide-imide and polyimide, which is applied in the field of preparation of polyamide-imide-polyimide copolymer wear-resistant self-lubricating molding compound, which can solve the problem of poor toughness of molded products, limited application range, and mold pressing problems. Problems such as high molding conditions, to achieve the effects of improved heat resistance, outstanding mechanical properties, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

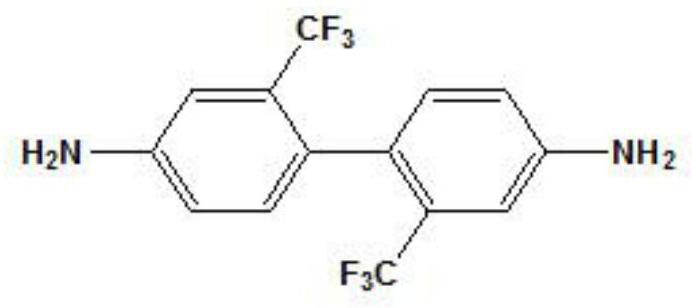

[0051] Differential DMAC2748 grams were put into the reactor, 320 g 2, 2'-bis (trifluoromethyl) -4,4-diaminipine was added under nitrogen protection, and all of them were dissolved in the diamine monomer. 260 grams of 4,4'-bisphenol A diethrhydrahydride in batches, high-speed stirring reaction time 24 h, batch of 1,2,4-blenedhenic anhydride 1,2,4-blenediphenylene dianer 1,07.1 grams, control material temperature -10 ~ 10 ° C during the whole process .

[0052] After the incubation was completed, 51.5 g of acidic triethylamine was added, and the dropwise time was controlled at 30 minutes, and the reaction was completed after 18 hours.

[0053] A mixture of 183.6 g of acetic anhydride was added dropwise to 121.2 g of triethylamine, and chemical imidization was carried out at room temperature, and the reaction time was 8 h.

[0054] The polyimide solution was poured into a large amount of water and then filtered, washed, and then filtered. The resin powder was dried in vacuo at 70 ° ...

Embodiment 2

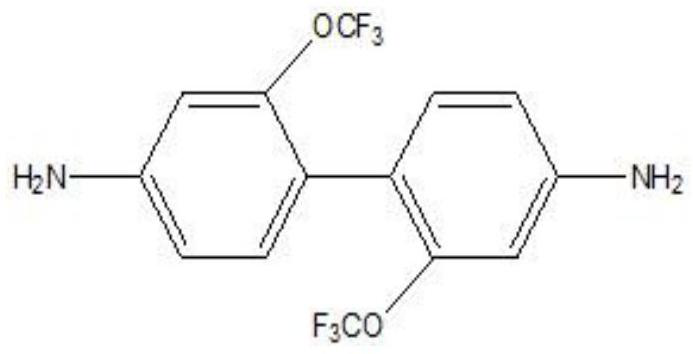

[0057] Diffissed DMAC2640 grams were put into the reactor, adding 352 g of 2,2'-bis (trifluoromethoxy)-biphenylenediamine under nitrogen, and after all of the monomide to be diamine monomer, batch Input 4,4'-phenylene oxodebrene terephthalic anhydride 201 grams, high-speed stirring reaction time 24 h, batch 1,2,4-blenedhenic anhydride 1,2,4-barenenic anhydride 1,27.1 grams, control material temperature -10 ~ 10 ° C during the whole process .

[0058] After the incubation was completed, 51.5 g of acidic triethylamine was added, and the dropwise time was controlled at 30 minutes, and the reaction was completed after 18 hours.

[0059] A mixture of 183.6 g of acetic anhydride was added dropwise to 121.2 g of triethylamine, and chemical imidization was carried out at room temperature, and the reaction time was 8 h.

[0060] The polyimide solution was poured into a large amount of water and then filtered, washed, and then filtered. The resin powder was dried in vacuo at 70 ° C for 12 h...

Embodiment 3

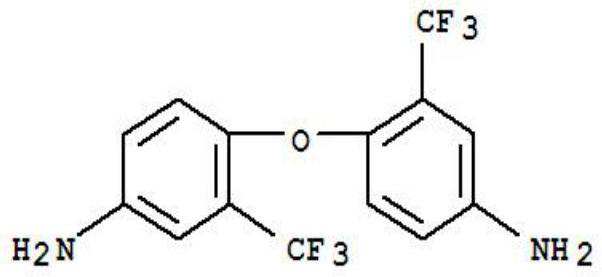

[0063] Differential DMAC2416 grams were put into the reactor, 336 g 2, 2'-bis (trifluoromethyl) -4,4'-diaminophenyl ether was added under nitrogen protection, and all of the monomide to be diamine monomer After dissolving, 3, 3 ', 4,4'-xinophenone tetramethrid dihydride, high-speed stirring reaction time 24 h, batching 1, 2, 4-blenediphenyl aionic anhydride 107.1 grams, control over the process Material temperature - 10 ~ 10 ° C.

[0064] After the incubation was completed, 51.5 g of acidic triethylamine was added, and the dropwise time was controlled at 30 minutes, and the reaction was completed after 12 hours.

[0065] A mixture of 183.6 g of acetic anhydride was added dropwise to 121.2 g of triethylamine, and chemical imidization was carried out at room temperature, and the reaction time was 8 h.

[0066] The polyimide solution was poured into a large amount of water and then filtered, washed, and then filtered. The resin powder was dried in vacuo at 70 ° C for 12 h.

[0067] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com