A film-forming performance control method of large-grained multi-layer brazed diamond grinding wheel electrolytic oxide film

A diamond grinding wheel, electrolytic oxidation technology, applied in the direction of electrolytic coating, anodic oxidation, coating, etc., can solve the problems of wear and abrasive grains that cannot fall off in time, reduce the quality of the processed surface, limit the application, etc., and achieve stable and efficient precision grinding , Improve the grinding surface quality, improve the effect of self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

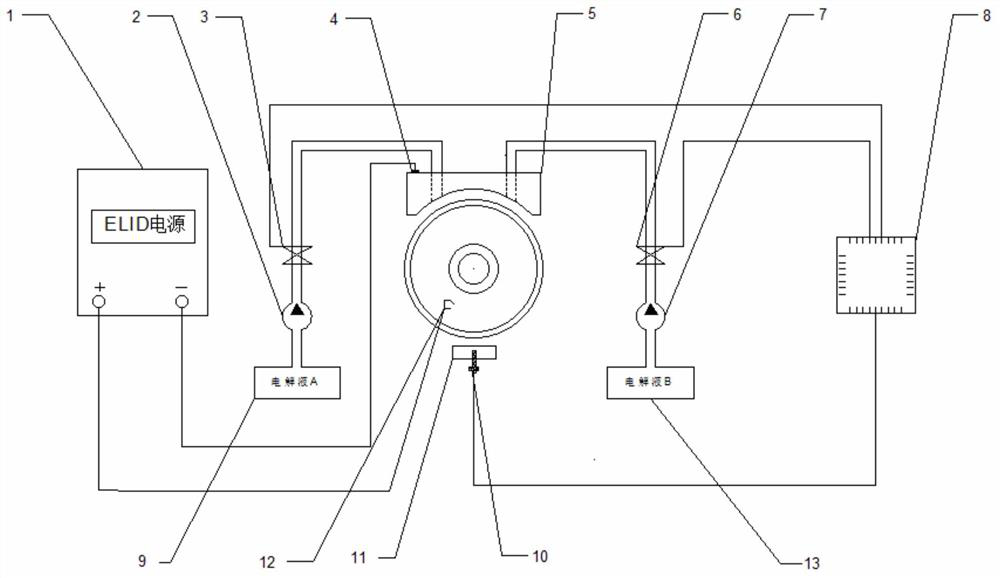

[0021] Such as figure 1 As shown, the electrolyte injection device used in the present invention includes an ELID pulse power supply 1, a first water pump 2, a first electromagnetic valve 3, a cathode terminal 4, a cathode block 5, a second electromagnetic valve 6, a second water pump 7, and a PLC Controller 8, first electrolytic cell 9, load cell 10, workpiece 11, brazing grinding wheel 12 and second electrolytic cell 13, the positive pole of ELID pulse power supply 1 is connected to brazing grinding wheel 12, and the negative pole is connected to cathode block through cathode terminal 4 5 connection, the first water pump 2 and the first electromagnetic valve 3 are connected to the first electrolytic cell 9, and communicate with the injection port on the cathode block 5 to realize the injection of the brazing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com