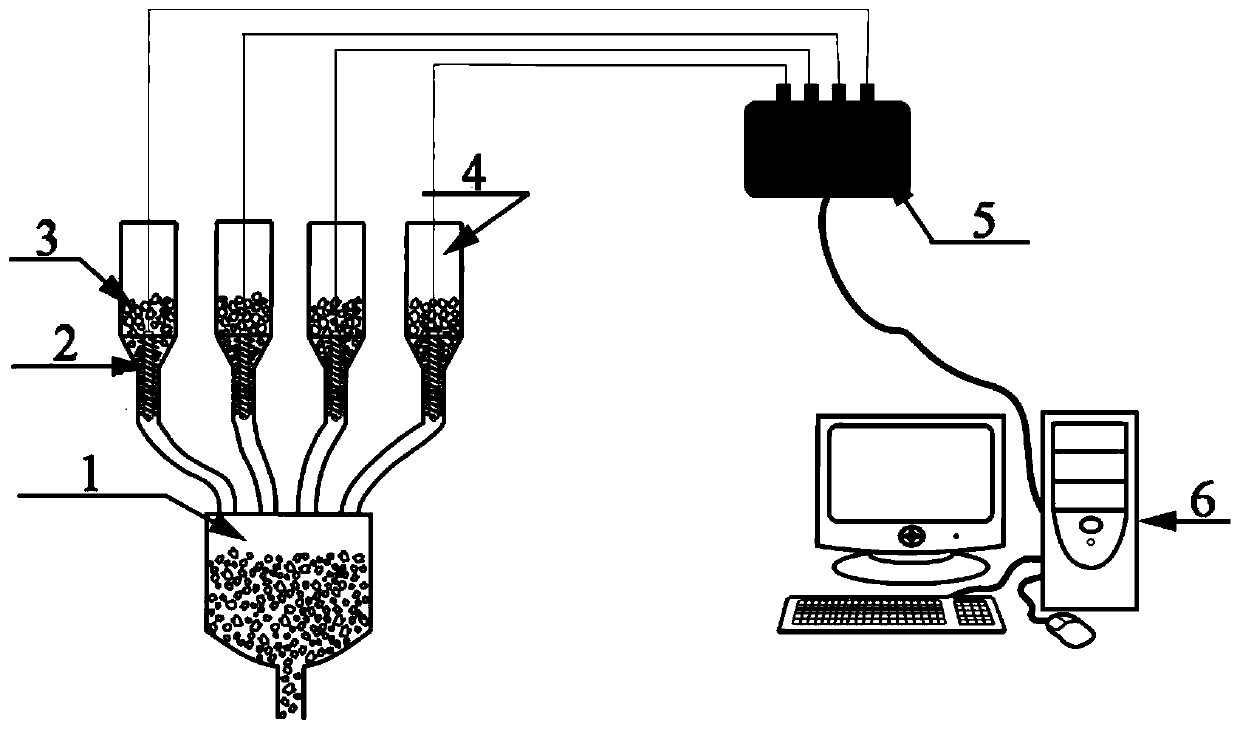

System and method for adjusting raw material flowing speeds in high-flux preparation of multi-element gradient materials

A technology of gradient materials and adjustment systems, applied in mixing methods, chemical instruments and methods, fluid mixers, etc., can solve the problems of restricting scientific and technological progress and social development, bottlenecks in material research and development, and high costs, so as to shorten the batching time, Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

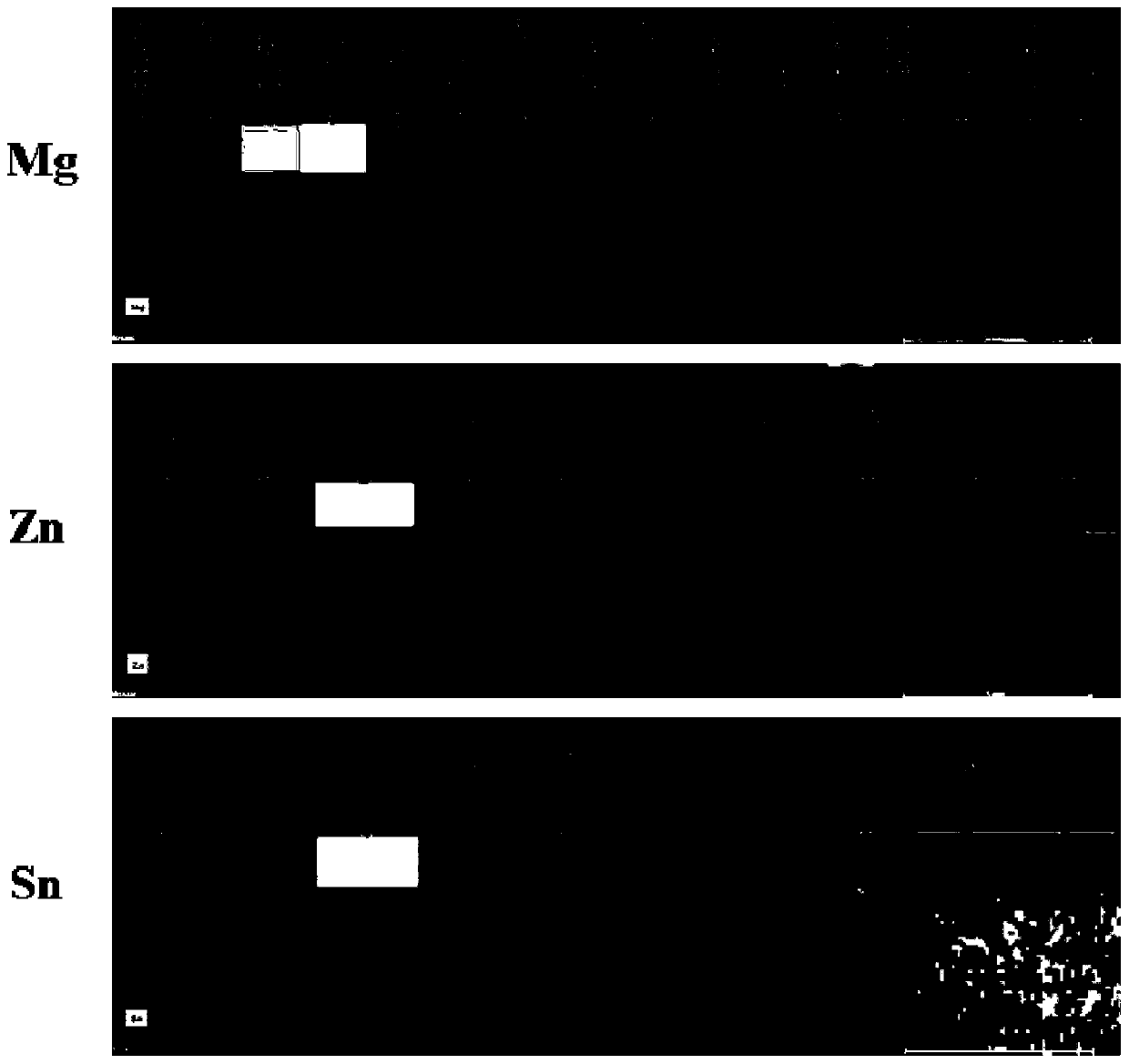

[0073] Design a Mg-Zn-Sn gradient alloy rod;

[0074] Measure the mass of certain pure magnesium granules, pure zinc granules, and pure tin (white tin) granules through a balance, and determine their volumes through measuring cups, etc., and divide the two to obtain pure magnesium granules, pure zinc granules, and pure tin (white tin) Particle bulk density ρ' Mg , ρ' Zn , ρ' Sn (unit: g / cm 3 );

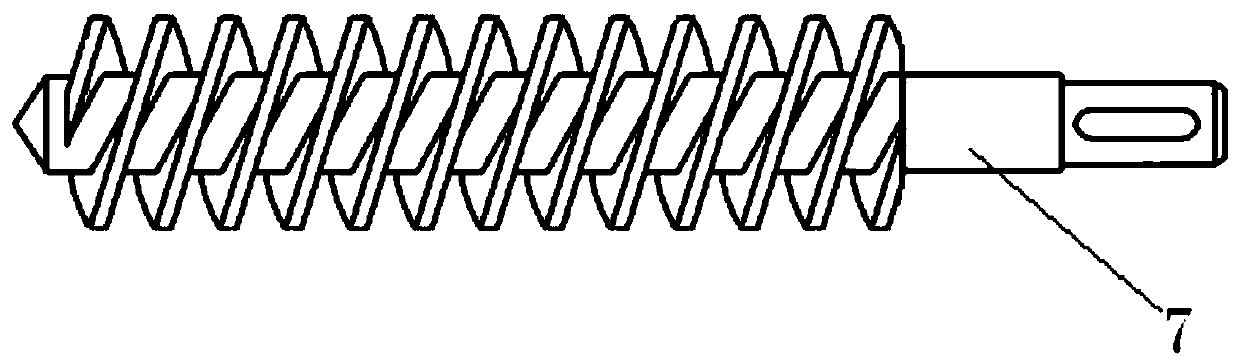

[0075] Select a certain pure magnesium particle, and calibrate its feeding speed in the three screw feeding pipelines of A, B, and C as Ⅹ A =0.254, X B =0.170, X C =0.170 (unit: g / circle), the bulk density of pure magnesium particles is ρ' Mg (unit: g / cm 3 );

[0076] Input rod length L=12cm, cross-sectional area S=7.07cm 2 , the number of segmental gradients along the length direction n=5;

[0077] Input the volume percentage change of each component in the bar (ie raw material components Mg, Zn, Sn): C Mg1 =99.38%, C Mg2 =99.26%, C Mg3 =99.13%, C Mg4 =99.01%, C Mg5 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com