A Method of Improving the Toughness of Thick Plate Core by Utilizing Descaler Box

A technology for descaling boxes and plate cores, which is applied in the field of metallurgy, can solve problems such as low toughness of the core, loose tissue density, and unsatisfactory service performance, and achieve the effect of increasing the density and improving the toughness of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

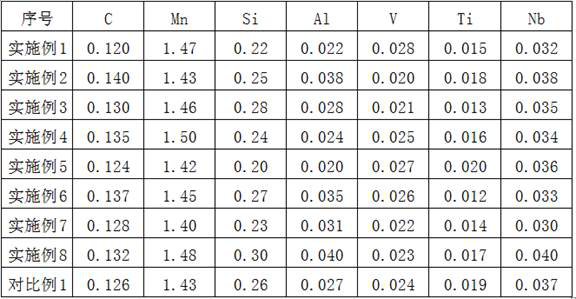

[0021] The thickness of the Q345E steel plate in this embodiment is 80 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0022] In this embodiment, the method for improving the toughness of the Q345E thick plate core by utilizing the descaling box includes the following steps:

[0023] (1) The thickness of the casting slab is 280mm, the angle of the descaling header is 16°, and the spraying width is 3020mm. The water pressure is 22MPa, the cooling time is 13s, the temperature difference between the surface layer and the core of the slab after leaving the descaling box is 220°C, and the first rough rolling is carried out 12s after cooling, and the rolling reduction is 18%;

[0024] (2) Before the third pass of rough rolling, the slab is moved to the descaling box for high-intensity cooling, the cooling water pressure is 22MPa, and the cooling time is 8s. After leaving the descaling box, the temperature difference between the surface...

Embodiment 2

[0027] The thickness of the Q345E steel plate in this embodiment is 40mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0028] In this embodiment, the method for improving the toughness of the Q345E thick plate core by utilizing the descaling box includes the following steps:

[0029] (1) The thickness of the casting slab is 220mm, the angle of the descaling header is 18°, and the width of the water spray is 3160mm. The water pressure is 20MPa, the cooling time is 10s, the temperature difference between the surface layer and the core of the slab after leaving the descaling box is 254°C, and the first rough rolling is carried out 14s after cooling, and the rolling reduction is 20%;

[0030] (2) Before the third pass of rough rolling, the slab is moved to the descaling box for high-intensity cooling, the cooling water pressure is 20MPa, and the cooling time is 10s. After leaving the descaling box, the temperature difference between t...

Embodiment 3

[0033] The thickness of the Q345E steel plate in this embodiment is 40mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0034] In this embodiment, the method for improving the toughness of the Q345E thick plate core by utilizing the descaling box includes the following steps:

[0035] (1) The thickness of the casting slab is 280mm, the angle of the descaling header is 14°, and the water spray width is 3090mm. After the slab is released from the heating furnace, it is moved to the descaling box for high-intensity cooling before the first pass of rough rolling. The water pressure is 24MPa, the cooling time is 15s, the temperature difference between the surface layer and the core of the slab after leaving the descaling box is 276°C, and the first rough rolling is carried out 10s after cooling, and the rolling reduction is 19%;

[0036] (2) Before the third pass of rough rolling, the slab is moved to the descaling box for high-intensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com