Macromolecular material with water-response bidirectional-reversible shape memory function and preparation method therefor

A technology for polymer materials and memory materials, which is applied in the field of polymer materials with water-responsive two-way reversible shape memory function and the field of preparation thereof, can solve problems such as polymers without shape memory, and achieves simple and diverse preparation methods. Simple and easy to trigger effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A polymer material with a water-responsive two-way reversible shape memory function, the raw materials of which are as follows:

[0060] a) polyethylene glycol diacrylate (PEGDA): Mw=8000, Alfa Aesar company;

[0061] b) n-butyl acrylate (BA): Aladdin Reagent (Shanghai) Co., Ltd.;

[0062] c) benzoin dimethyl ether, Sigma-Aldrich company;

[0063] Preparation:

[0064] Preparation by bulk polymerization: Weigh a certain amount of PEGDA and BA (0wt% ~ 60wt%), add benzoin dimethyl ether, the amount added is 0.4% of the total mass of the system, dissolve it at 70°C, stir evenly and pour Put it into a sealed glass abrasive tool, cure it under ultraviolet light for 30 minutes, and then further cure it at 90°C for 1 hour. A water-responsive two-way shape memory material with a reversible driving phase under constant external force is obtained.

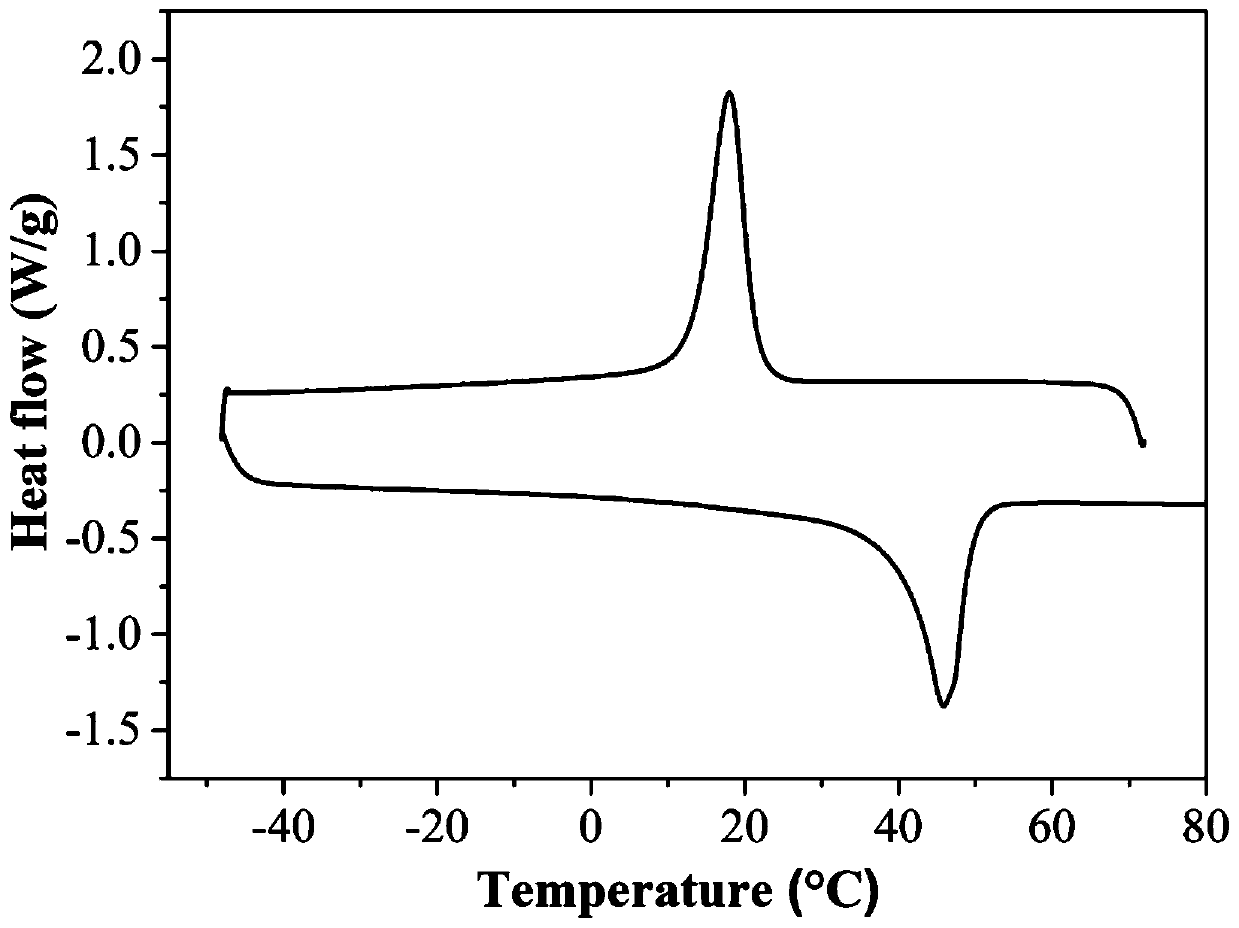

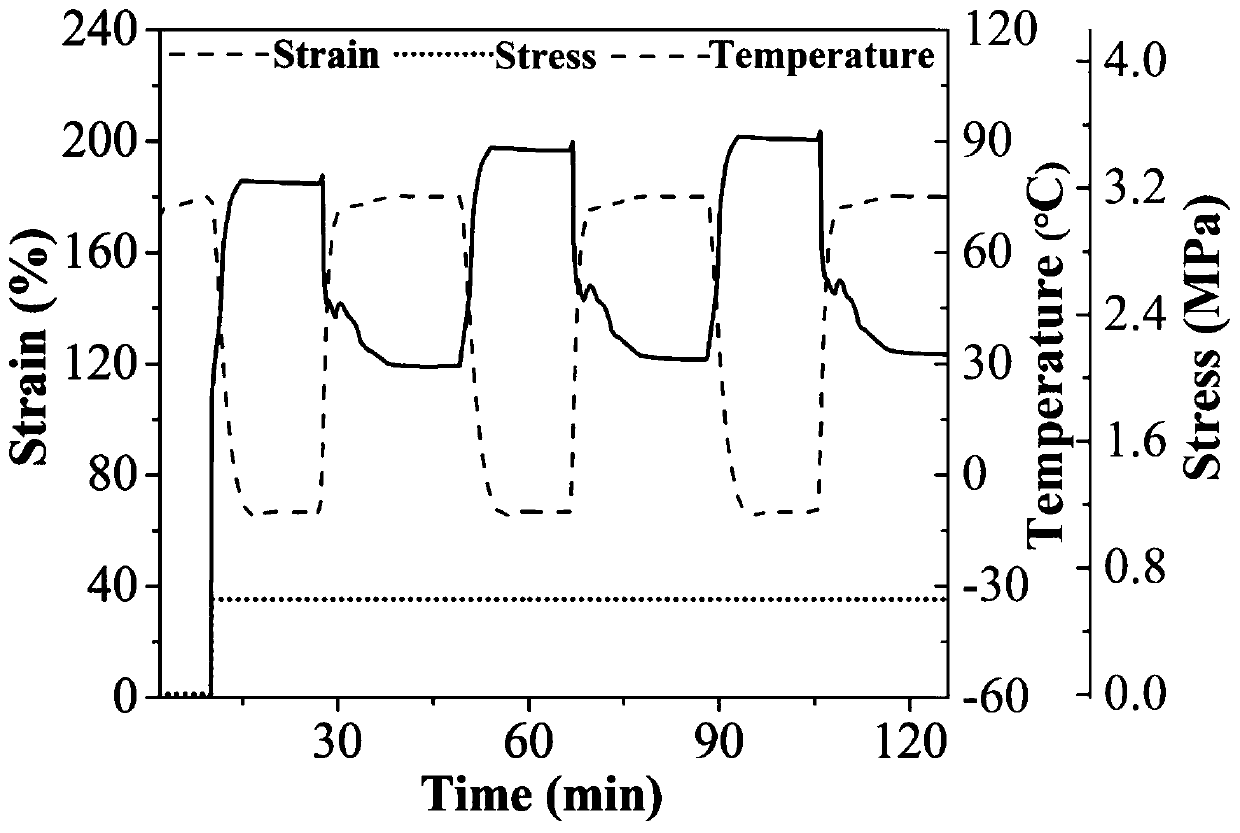

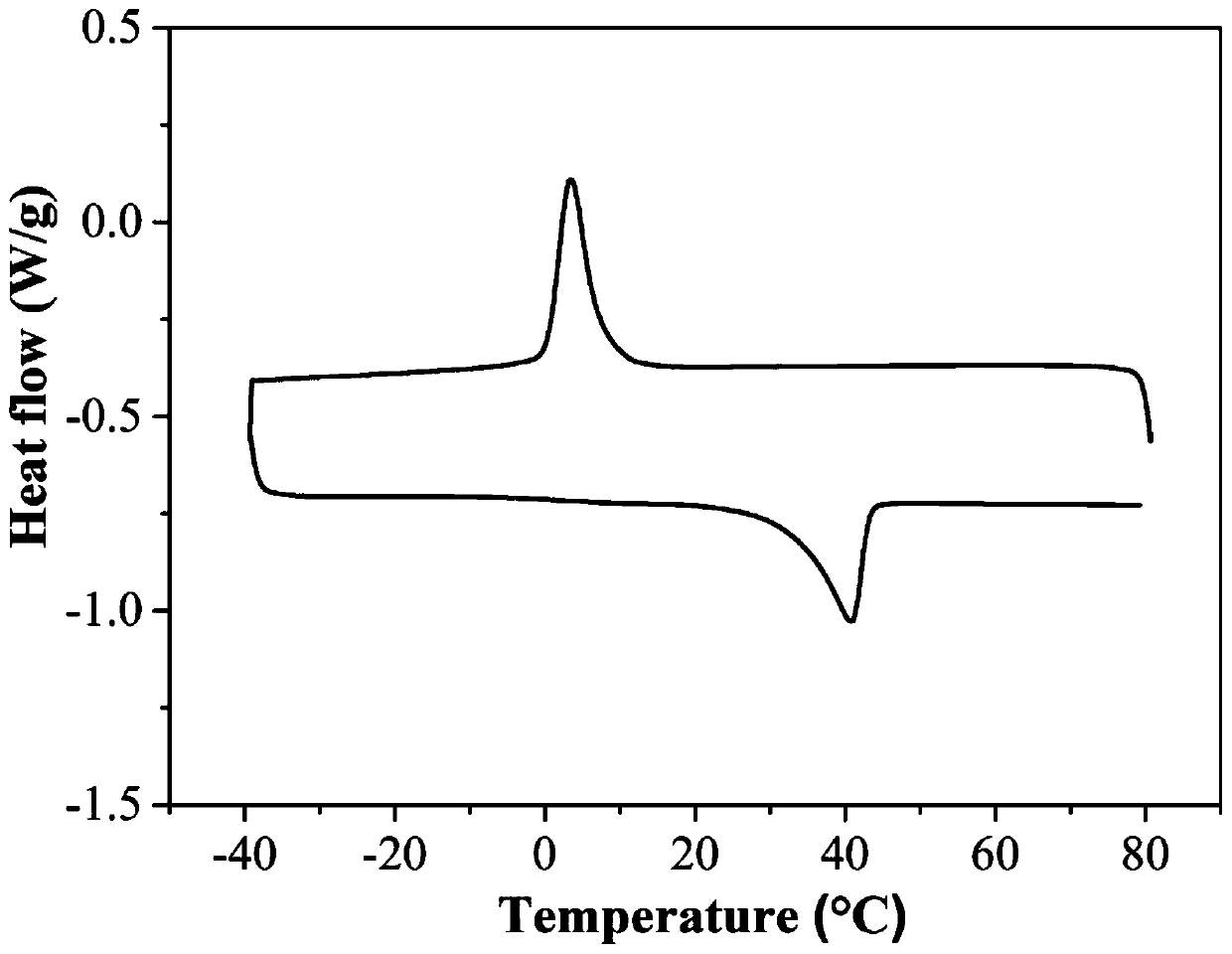

[0065] When the BA content is 50wt%, the melting point of the material after cross-linking and curing is 45°C, and the enthalpy ...

Embodiment 2

[0067] A polymer material with a water-responsive two-way reversible shape memory function, the raw materials of which are as follows:

[0068] a) polyethylene glycol (PEG): Mw=2000, Sigma-Aldrich company

[0069] b) Hexamethylene diisocyanate (HDI): Sigma-Aldrich company;

[0070] c) Dibutyltin dilaurate (DBTDL): TCI Company;

[0071] d) Butanediol (BDO): TCI Company;

[0072] e) pentaerythritol: TCI company;

[0073] Preparation:

[0074] Preparation by bulk polymerization: Vacuum dry 3g PEG at 110°C for 2h, add three drops of catalyst DBTDL, 0.1gBDO and 0.1g pentaerythritol, stir evenly, add equistoichiometric HDI, react at 85°C for 2h, after the reaction is completed, react The solution was poured into a polytetrafluoroethylene mold, reacted at 80°C for 24 hours, and then dried at 80°C to obtain a reversible water-responsive two-way shape memory material under constant external force.

[0075] After testing, the melting point of the material is 41°C. When the constant...

Embodiment 3

[0077] A polymer material with a water-responsive two-way reversible shape memory function, the raw materials of which are as follows:

[0078] a) Polyethylene glycol diacrylate (PEGDA): Mw=4000, Alfa Aesar company;

[0079] b) tetrakis (3-mercaptopropionic acid) pentaerythritol ester, Sigma-Aldrich;

[0080] c) Triethylamine catalyst, Sinopharm Chemical Reagent Co., Ltd.

[0081] Preparation:

[0082] According to the molar ratio of PEGDA and tetrakis (3-mercaptopropionic acid) pentaerythritol ester is 2:1, make 40wt% dimethylformamide solution, mix well, add 1wt% triethylamine, pour into tetrafluoroethylene abrasive tool , cured at 80°C for 6h, and then dried in a vacuum oven at 80°C to remove residual DMF. The cured sample was removed from the mold to obtain a reversible water-responsive two-way shape memory material under constant external force.

[0083] After testing, the melting point of the material is 48°C. When the constant external force is 0.3MPa, T high and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com