Optical fiber ring packaging structure

A technology of packaging structure and fiber optic ring, which is applied in the field of fiber optic gyro, to achieve the effects of improving connection strength, improving scale factor stability, and low mechanical stress sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

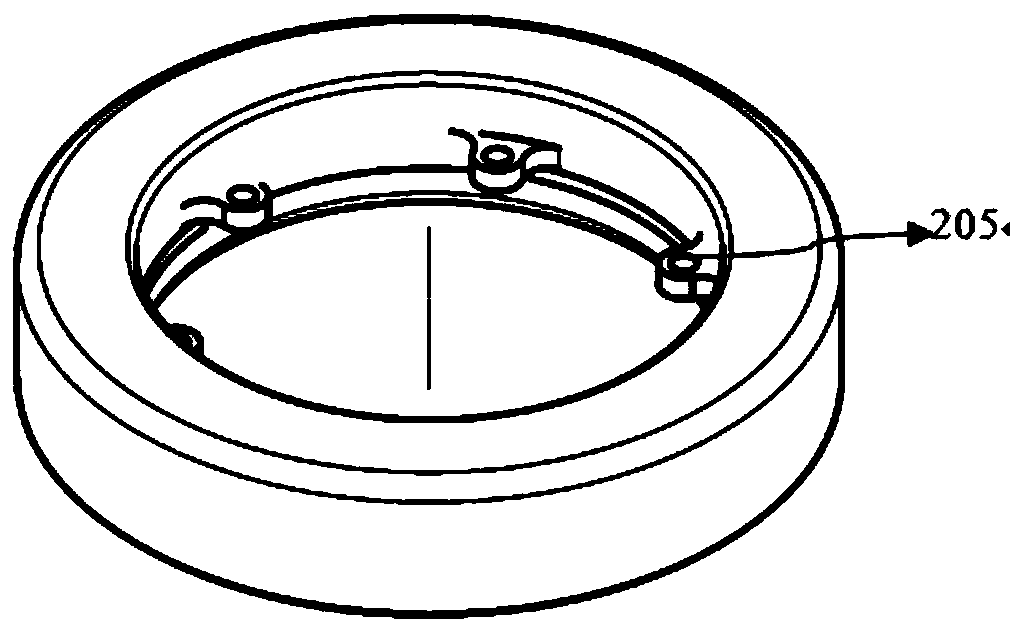

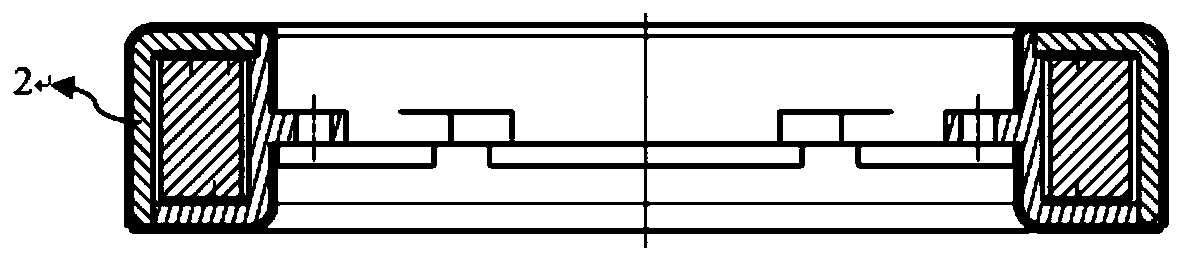

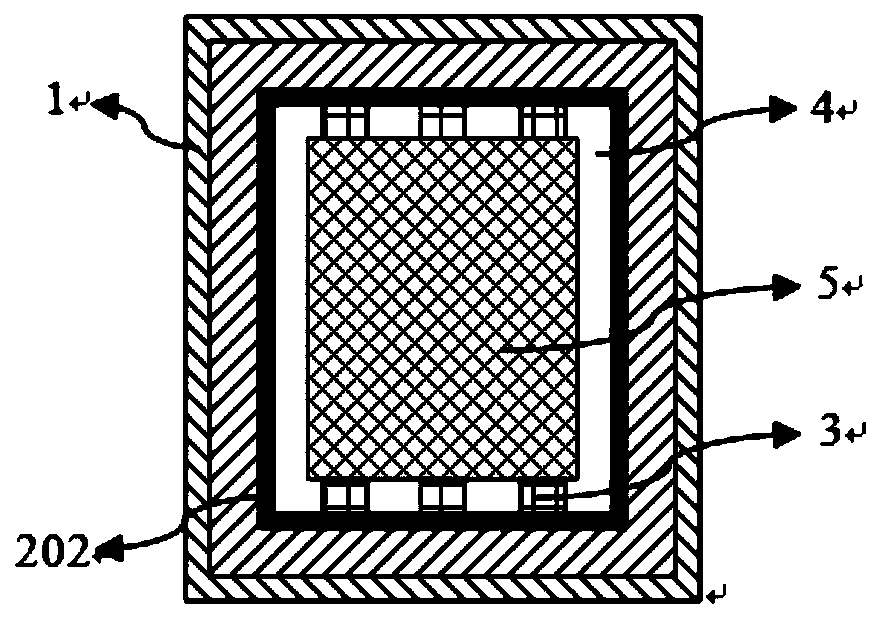

[0030] figure 1 It is the overall structure diagram of the optical fiber ring packaging structure, such as figure 1 As shown, the present invention provides an optical fiber ring packaging structure. figure 2 is a cross-sectional view of the optical fiber ring package structure, image 3 Schematic diagram of the optical fiber ring packaging structure, combined with figure 2 and image 3 As shown, the optical fiber ring packaging structure includes a magnetic shielding layer 1 , a thermal control layer 2 , an adhesive layer 3 , an air gap 4 , and an optical fiber ring 5 . The thermal control layer 2 is a hollow annular body structure, and the optical fiber ring 5 is arranged inside the hollow annular body of the thermal control layer 2. The upper side and the lower side of the optical fiber ring 5 pass through the inner surface of the adhesive layer 3 and the thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com