High-emissivity infrared radiation coating layer material system used in high temperature environment (800 DEG C) and preparation method for high-emissivity infrared radiation coating layer material system

A technology of infrared radiation coating and high emissivity, which is applied in the direction of coating, metal material coating process, spray evaporation, etc., can solve the problems of unsatisfactory thermal shock resistance, low bonding strength, and unusability, and achieve production High efficiency, mature preparation process and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-temperature high-emissivity infrared radiation coating material system, wherein SiO 2 45% (mass ratio), Cr 2 o 3 40%, TiO 2 15%.

[0031] The preparation method comprises the following steps:

[0032] (1) take three kinds of material powders according to mass ratio;

[0033] (2) Carry out low-energy ball milling in a horizontal ball mill, using a polyurethane ball mill tank, zirconia grinding balls (ball-to-material ratio is 3:1), deionized water as a dispersion medium, and adding hydroxymethyl fiber equivalent to 1.0% of the raw material powder mass element, the ball milling time is 48h;

[0034] (3) Agglomerated powder was obtained by granulating by spray drying process, wherein the air inlet temperature was 200°C, the air outlet temperature was 80°C, the plunger pump speed was 1000r / min, and the atomization disk speed was 16000r / min;

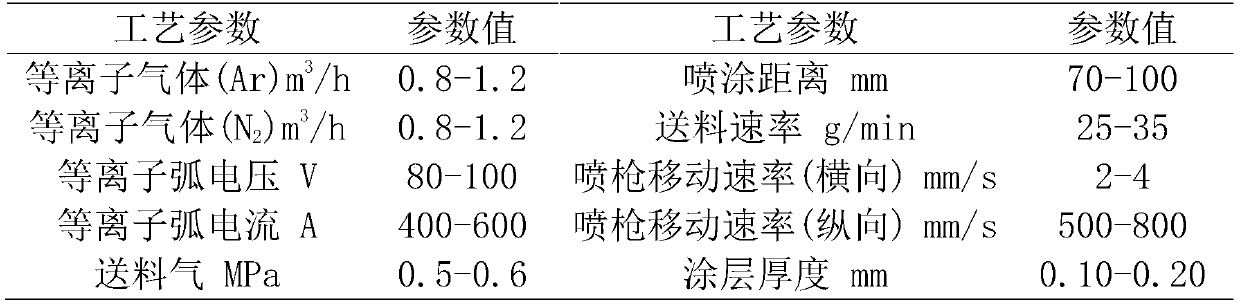

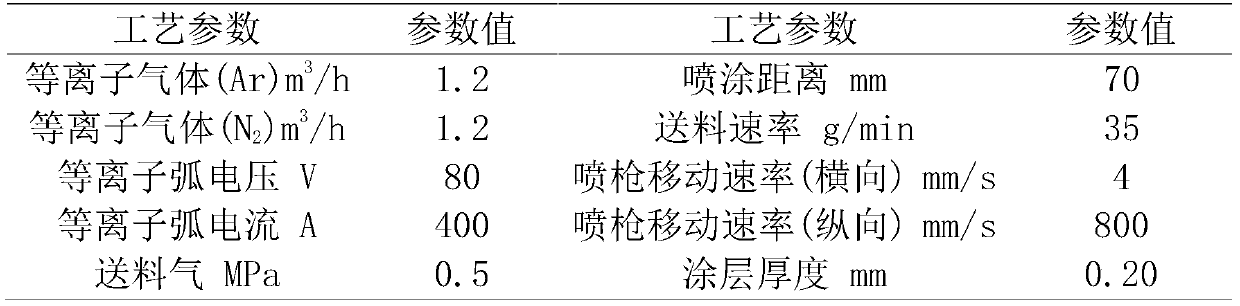

[0035] (4) Calcining the agglomerated powder at high temperature to obtain a finished powder suitable for the plasma ...

Embodiment 2

[0043] A high-temperature high-emissivity infrared radiation coating material system, wherein SiO 2 50% (mass ratio), Cr 2 o 3 40%, TiO 2 10%.

[0044] The preparation method comprises the following steps:

[0045] (1) take three kinds of material powders according to mass ratio;

[0046] (2) Carry out low-energy ball milling in a horizontal ball mill, using a polyurethane ball mill tank, zirconia grinding balls (ball-to-material ratio is 3:1), deionized water as a dispersion medium, and adding hydroxymethyl fiber equivalent to 2.0% of the raw material powder mass element, the ball milling time is 60h;

[0047] (3) Agglomerated powder was obtained by granulating by spray drying process, wherein the temperature of the air inlet was 180°C, the temperature of the air outlet was 50°C, the speed of the plunger pump was 800r / min, and the speed of the atomizing disc was 20000r / min;

[0048] (4) Calcining the agglomerated powder at high temperature to obtain a finished powder...

Embodiment 3

[0055] A high-temperature high-emissivity infrared radiation coating material system, wherein SiO 2 55% (mass ratio), Cr 2 o 3 40%, TiO 2 5%.

[0056] The preparation method comprises the following steps:

[0057] (1) take three kinds of material powders according to mass ratio;

[0058] (2) Carry out low-energy ball milling in a horizontal ball mill, using a polyurethane ball mill tank, zirconia grinding balls (ball-to-material ratio is 3:1), deionized water as a dispersion medium, and adding hydroxymethyl fiber equivalent to 1.5% of the raw material powder mass element, the ball milling time is 72h;

[0059] (3) Agglomerated powder was obtained by granulating by spray drying process, wherein the temperature of the air inlet was 150°C, the temperature of the air outlet was 30°C, the speed of the plunger pump was 500r / min, and the speed of the atomizing disc was 22000r / min;

[0060] (4) Calcining the agglomerated powder at high temperature to obtain a finished powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com