High surface quality 1200mpa grade hot-dip galvanized dual-phase steel and production method thereof

A production method and high-surface technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as increased production difficulty, decreased corrosion resistance, and reduced toughness of steel by AlN particles. It has the effect of small loss of production medium, improvement of performance stability and improvement of welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

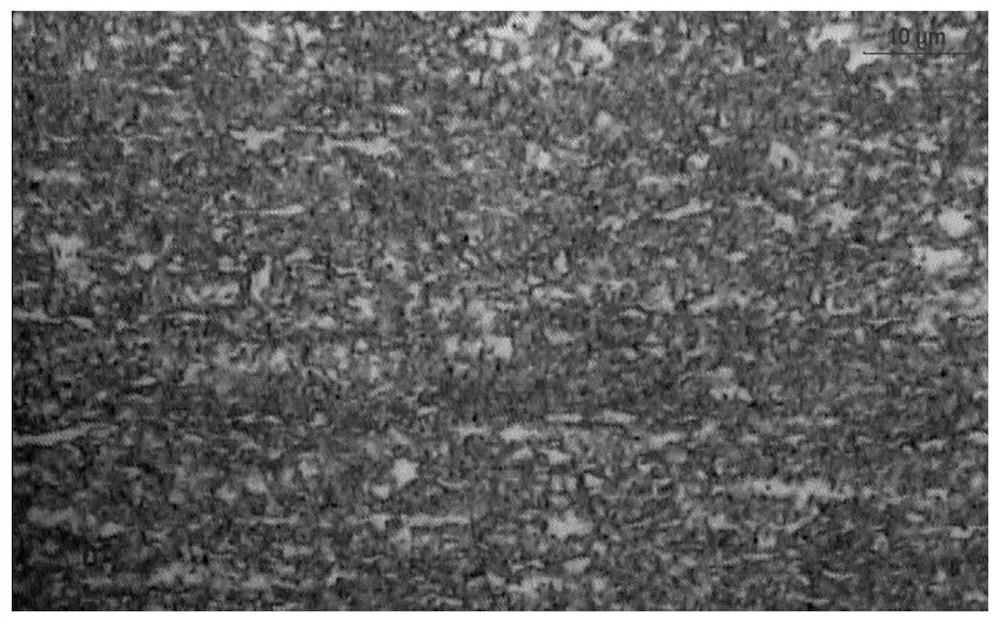

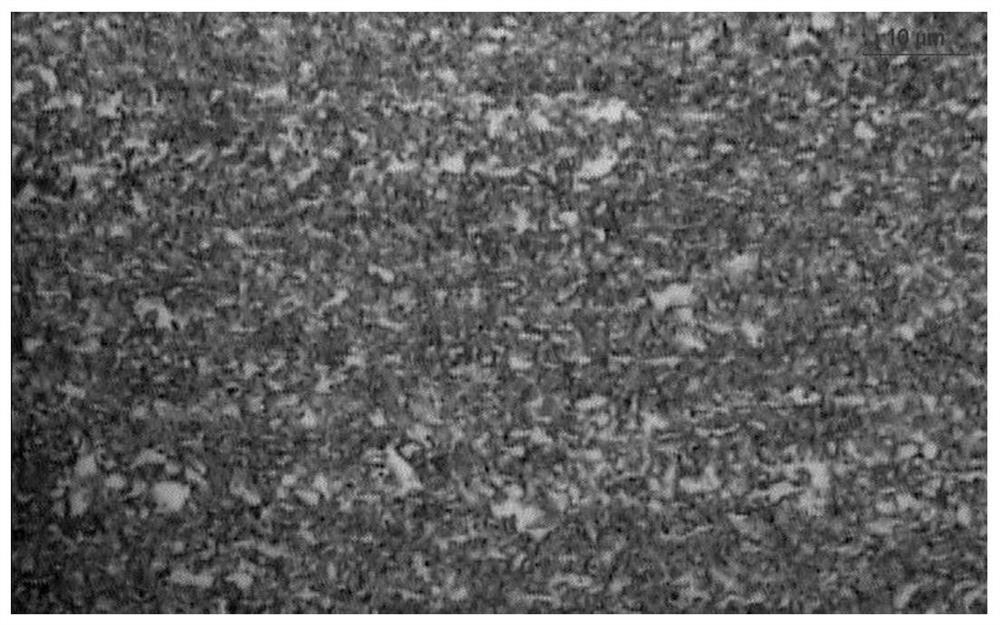

[0039] The 1200MPa grade hot-dip galvanized dual-phase steel provided by the invention adopts a low-C design, which can reduce the C equivalent of the material and obtain good welding performance. The content of metallurgical components C, Si, and Mn has an important impact on the final performance of the dual-phase steel. An important factor affecting the content and stability of austenite. The alloying element Ti has a certain influence on the ductility of the dual-phase steel in this test process. It combines with C in the material to precipitate fine and dispersed TiC particles in the ferrite matrix, thereby playing a role of precipitation strengthening and reducing the ferrite. Compared with martensite, it can improve the hardenability of austenite islands, which is conducive to the production of highly extensible ferrite. Nb also has a significant effect on martensite nucleation and grain refinement, which can increase the tensile strength ; Part of B in the steel exists...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com