Nitrogen-reinforced FeCrCoMnNi high-entropy alloy and preparation method thereof

A high-entropy alloy and high-temperature technology, applied in the field of high-entropy alloys, can solve the problems of restricting dynamic recrystallization grain refinement, restricting thermal deformation fragmentation, and coarse grain size, so as to eliminate cracking problems and eliminate dendrites. High degree of segregation and tissue homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The invention provides a nitrogen-strengthened FeCrCoMnNi high-entropy alloy. The element composition (mass percentage) of the nitrogen-containing FeCrCoMnNi high-entropy alloy used in the nitrogen-strengthened FeCrCoMnNi high-entropy alloy is: iron (5-35), manganese (5-35 ), cobalt (5~35), chromium (5~35), nickel (5~35), nitrogen (0.01~0.4).

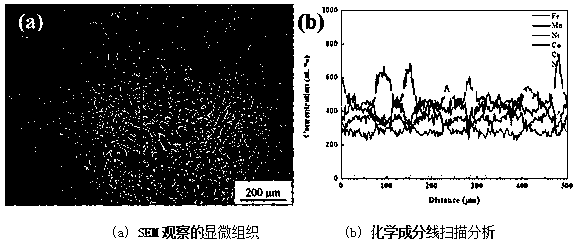

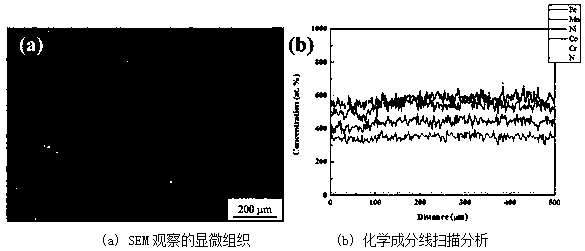

[0029] The invention provides a method for preparing a nitrogen-strengthened FeCrCoMnNi high-entropy alloy. The strong thermal shear deformation generated by friction stir processing is used to fragment the dendrites in the structure of the as-cast nitrogen-strengthened FeCrCo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com