Method and device for multistage and multi-effect catalytic advanced oxidation coking wastewater advanced treatment

A technology of coking wastewater and advanced oxidation, applied in multi-stage water treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of reducing unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited thereto.

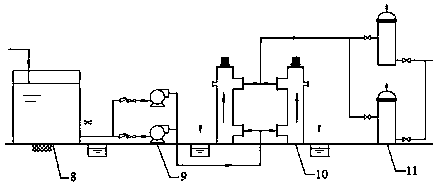

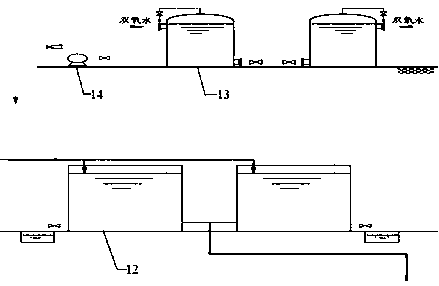

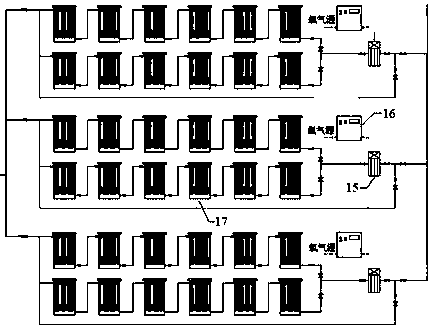

[0042] Such as Figure 1 to Figure 7As shown, the multi-stage multi-effect catalytic advanced oxidation coking wastewater advanced treatment device of the present invention includes a pretreatment catalytic ozone oxidation air flotation treatment system A, a multi-effect filtration treatment system B, a hydrogen peroxide contact oxidation system C, a hydrogen peroxide / ultraviolet heterogeneous catalytic nano Bubble ozone oxidation system D, multiphase filtration and catalytic digestion system E and water outlet / backwashing system F;

[0043] The pretreatment catalytic ozonation air flotation treatment system A includes an ozone generator 1, a dissolved air flotation device 2, a dissolved air tank 3, an air compressor 4 and a mud / oil pool 5 connected in sequence, and the described The dissolved air flotation device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com