Spinel type nanocrystalline material and preparation method and application thereof

A nanocrystalline material and spinel-type technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as the difficulty in preparing spinel-type oxides, and achieve breakthroughs in electrochemical performance and high specific capacity , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

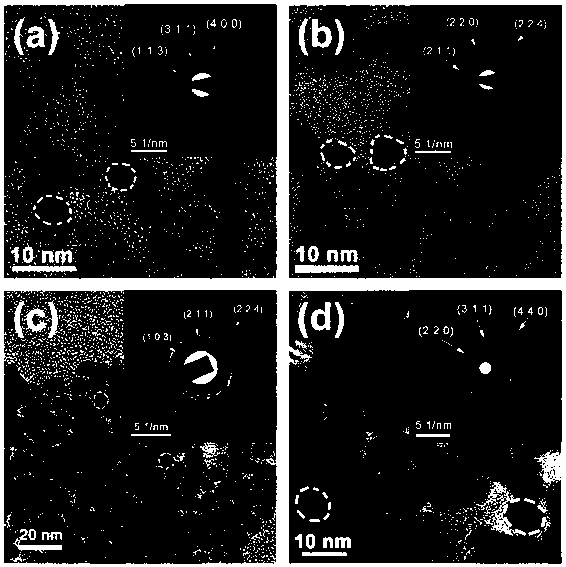

Image

Examples

Embodiment 1

[0024] Weigh 1.5 mmol commercial grade cobalt acetate tetrahydrate and 3 mmol commercial grade manganese acetate tetrahydrate, add 225 mL ethanol and 1.5 mL ammonia water, mix well in a 250 mL three-necked flask, and heat the reaction system in a hot oil bath at 80 °C for 2 h. After the reaction was completed, the reaction system was cooled to room temperature, and the obtained solution was transferred to a polytetrafluoroethylene liner of a small laboratory reactor, and the reactor was heated in a blast oven at 150 °C for 10 h. After the reaction is over, wait for the reaction system to cool down to room temperature, transfer the obtained product to a Buchner funnel, cover the inside of the funnel with an organic microporous filter membrane (0.22 μm in pore size), add ethanol to fill the funnel volume, and filter until it is completely drained. Wash solution, repeat 3 times. The washed product was transferred to filter paper and dried in a forced air oven at 60 °C for 12 h to...

Embodiment 2

[0026] Weigh 4.5 mmol of commercial grade manganese acetate tetrahydrate, add 225 ml of ethanol and 1.5 mL of ammonia water, mix well in a 250 mL three-necked flask, and heat the reaction system in a hot oil bath at 80 °C for 2 h. After the reaction was completed, the reaction system was cooled to room temperature, and the obtained solution was transferred to a polytetrafluoroethylene liner of a small laboratory reactor, and the reactor was heated in a blast oven at 150° C. for 10 h. After the reaction is over, wait for the reaction system to cool down to room temperature, transfer the obtained product to a Buchner funnel, cover the inside of the funnel with an organic microporous filter membrane (0.22 μm in pore size), add ethanol to fill the funnel volume, and filter until it is completely drained. Wash solution, repeat 3 times. The washed product was transferred to filter paper and dried in a forced air oven at 60 °C for 12 h to obtain Mn 3 o 4 Nanocrystalline powder, the...

Embodiment 3

[0028] A kind of water system secondary zinc ion battery, this water system secondary zinc ion battery cathode material adopts the CoMn described in embodiment 1 2 o 4 Nanocrystalline. Weigh the positive electrode material CoMn with a mass ratio of 7:2:1 2 o 4 Nanocrystals, conductive agent acetylene black and binder PVDF, the positive electrode material Mn 3 o 4 The nanocrystals and conductive agent acetylene black were thoroughly ground in a mortar, PVDF was placed in a small beaker, NMP was added and stirred for 1 hour until completely dissolved. Add the ground mixture into the dissolved PVDF, add appropriate amount of NMP to make the viscosity appropriate, and stir for 8 hours. Coat the slurry on 10 μm 304L stainless steel foil or carbon paper with an areal density of about 2mg / cm 2 , dried in a vacuum oven at 80° C. for 12 hours, cooled to room temperature, and cut into circular positive electrode pieces with a diameter of 15 mm.

[0029] The above-mentioned circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com