cuh catalyst, cuh derived catalyst, preparation method and application

A technology for catalysts and reaction products, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsuitability for large-scale production, poor product selectivity, complex preparation methods, etc. The effect of reducing activity performance, excellent catalytic stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

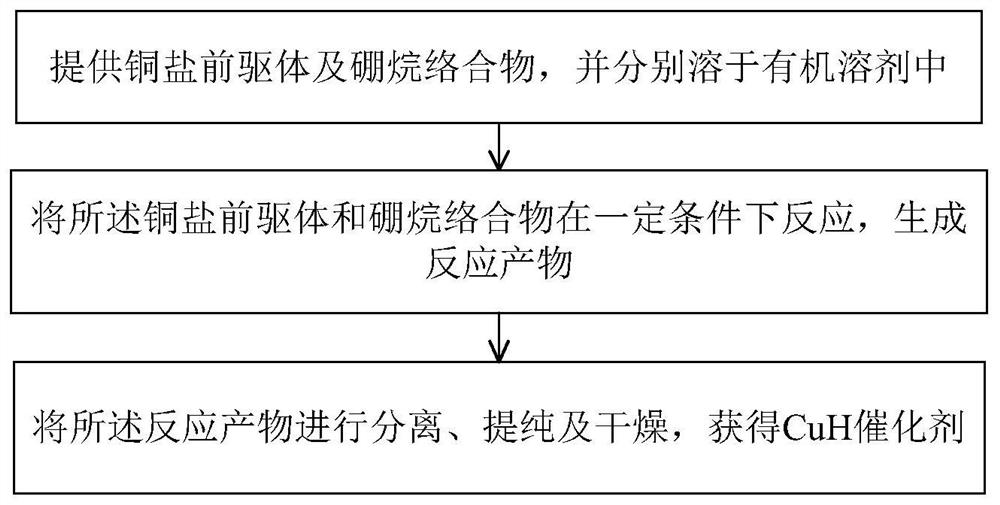

[0061] To prepare CuH catalyst and CuH derivatized catalyst, the specific steps are as follows:

[0062] Accurately weigh 10.871 g of borane tert-butylamine (86.97 g / mol) into a 50 mL beaker, then add ethanol to dissolve and dilute to a 50 mL volumetric flask to obtain a 2.5M borane tert-butylamine solution.

[0063] Accurately weigh 134.5 mg of anhydrous CuCl 2 (134.5g / mol) was added into a 500mL beaker, and then 200mL of ethanol was weighed and added, and placed in a 100W ultrasonic machine to dissolve at a constant temperature of 25°C and ultrasonically dissolved to form dissolved CuCl 2 solution.

[0064] Quantitatively take 2.5mL of the borane tert-butylamine solution and add the dissolved CuCl 2 In the solution, the ultrasonic reaction was maintained at a constant temperature for 2h.

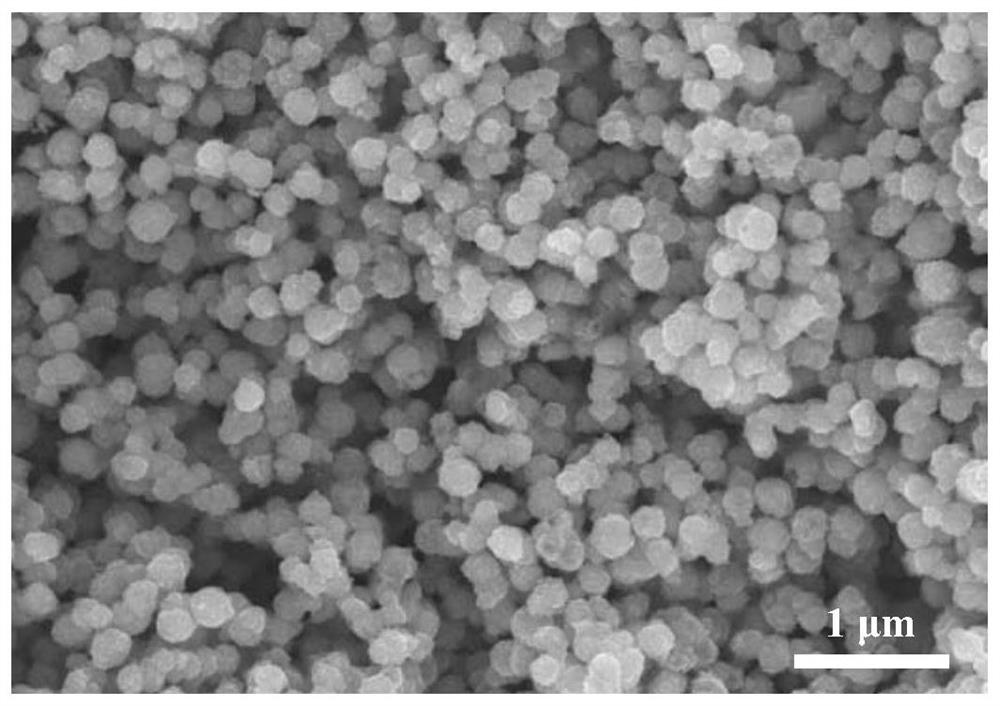

[0065] The above-reacted suspension was separated by suction filtration, and the obtained solid was dispersed and washed with 300 mL of ethanol in three times. Then, the obtained produ...

Embodiment 2

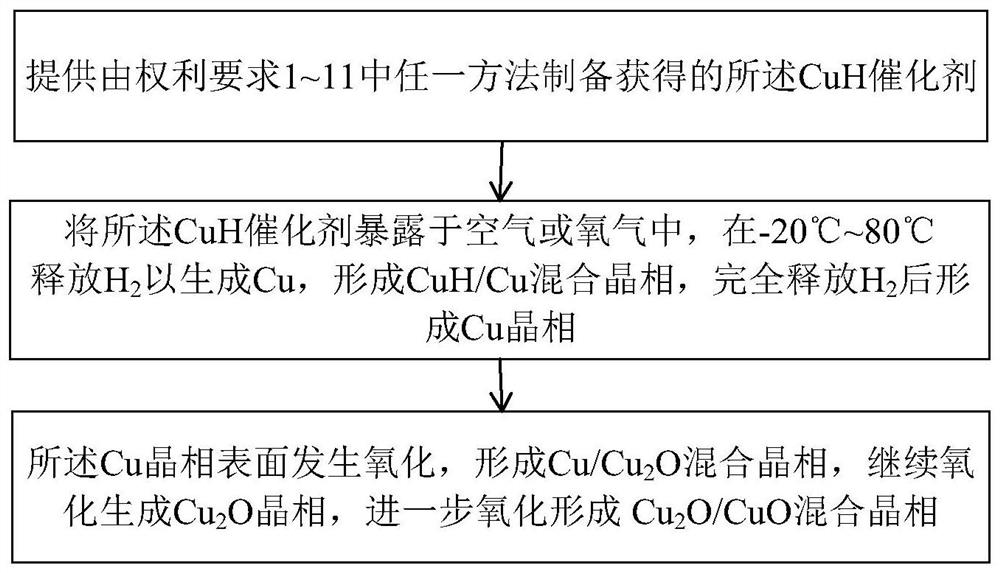

[0078] Accurately weigh 20 mg of Cu derivatized with CuH catalyst in Example 1 2 O / CuO mixed crystal phase catalyst, quantitatively pipet 0.96mL of ethanol and 0.04mL of Nafion solution (5wt.%), placed in a 100W ultrasonic machine, and ultrasonically dispersed for 60min. The CuH derivatized catalyst was drop-coated on the gas diffusion electrode substrate by drop-coating, and dried naturally to form a catalytic layer, with an effective catalytic area of 1 cm. 2 , the catalyst loading is 1 mgcm -2 . Wherein, the intermediate layer of the gas diffusion electrode substrate is supported by carbon paper treated with 20wt.% PTFE as the gas diffusion layer, and the CuH derivatized catalyst is drop-coated on one side of the intermediate layer as the catalytic layer. The other side of the middle layer is brushed with a PTFE hydrophobic layer or adhered to a PTFE polymer film. A flow electrolyzer is used, the cathode and anode chambers are separated by AT-1 anion exchange membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com