Method for preparing floating swimming micromachine

A technology of machines and metal balls, which is applied in the field of preparation of floating micromachines, can solve the problems of poor biocompatibility of chemical fuels, difficulty in applying to living organisms, and insufficient driving force of movement, etc., and achieve uniform size and non-toxicity Good, long storage time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

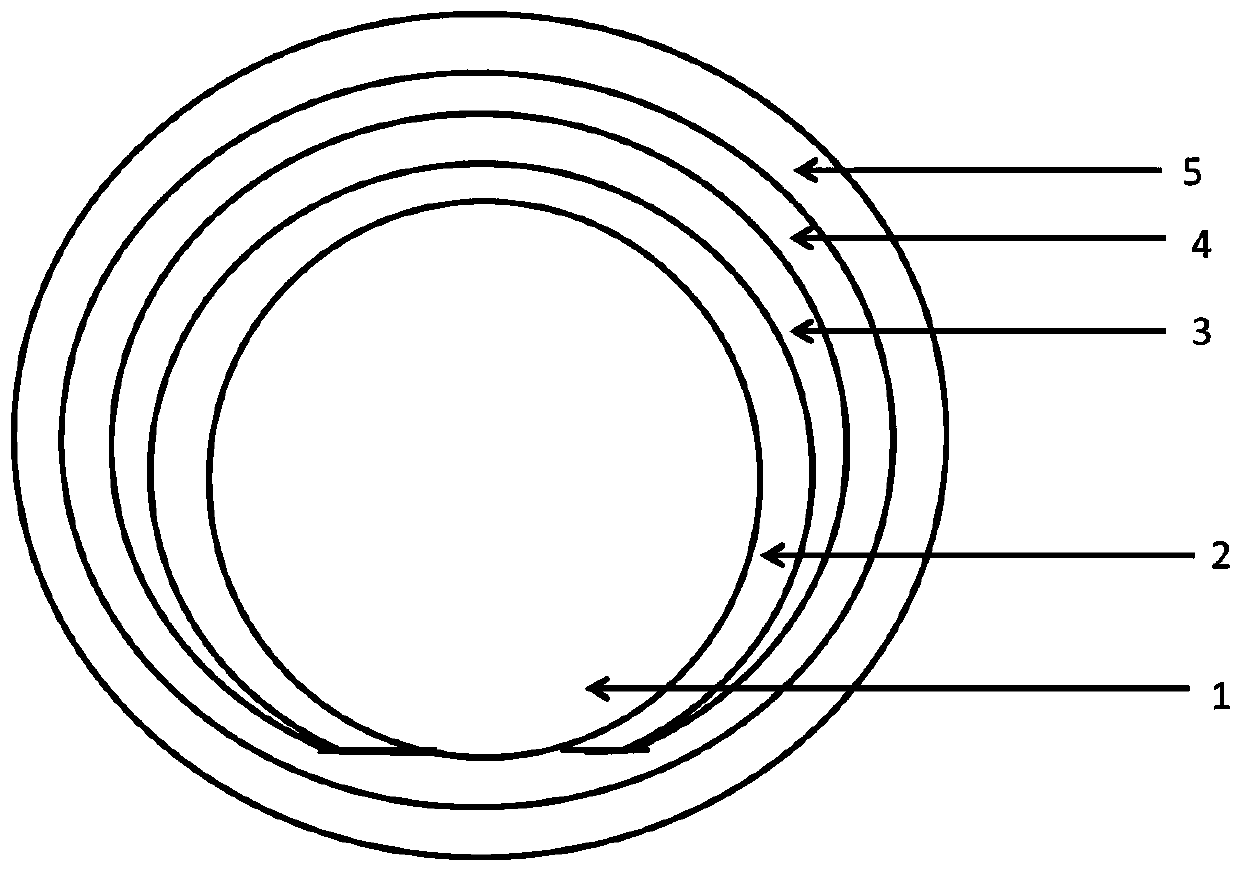

[0026] Embodiment one: if Figure 1-5 Shown, the preparation method of a kind of floating swimming micromachine involved in this embodiment, the optimum scheme of this method:

[0027] Step 1: Wash the magnesium spheres with an average size of 10 μm with acetone, isopropanol and ethanol three times respectively.

[0028] Step 2: Disperse the cleaned magnesium balls into water, drop a solution containing metal balls at a concentration of 2mg / ml on the glass slide with a pipette gun, and then dry it on a slope with an inclination angle of 45 degrees.

[0029] Step 3: Decorate gold with a thickness of 10 nm on the surface of the glass sheet by electron beam evaporation.

[0030] Step 4: Spray the polyethylene terephthalate onto the surface of the glass sheet.

[0031] Step 5: The metal balls are separated from the surface of the glass sheet by ultrasonic or mechanical means, then added to the gelatin solution, and the solution is slowly heated to 60°C.

[0032] Step 6: Inject ...

Embodiment 2

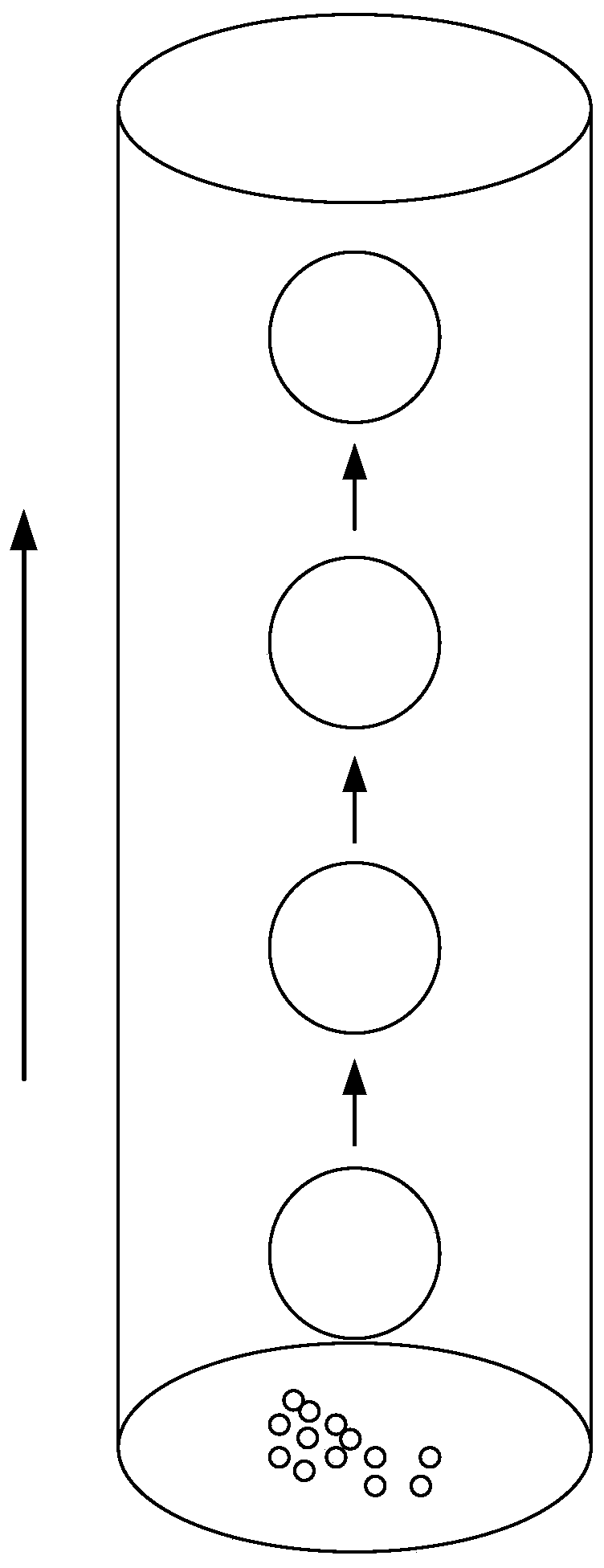

[0038] Embodiment two: if figure 2 Shown, the application of the preparation method of a kind of floating swimming micromachine involved in this embodiment, figure 2 The direction of the middle arrow is the movement direction of the floating robot. Putting the prepared floating micromachine into the water can control the movement direction and speed of the floating micromachine in the water. The movement mode in the water is driven by air bubbles.

Embodiment 3

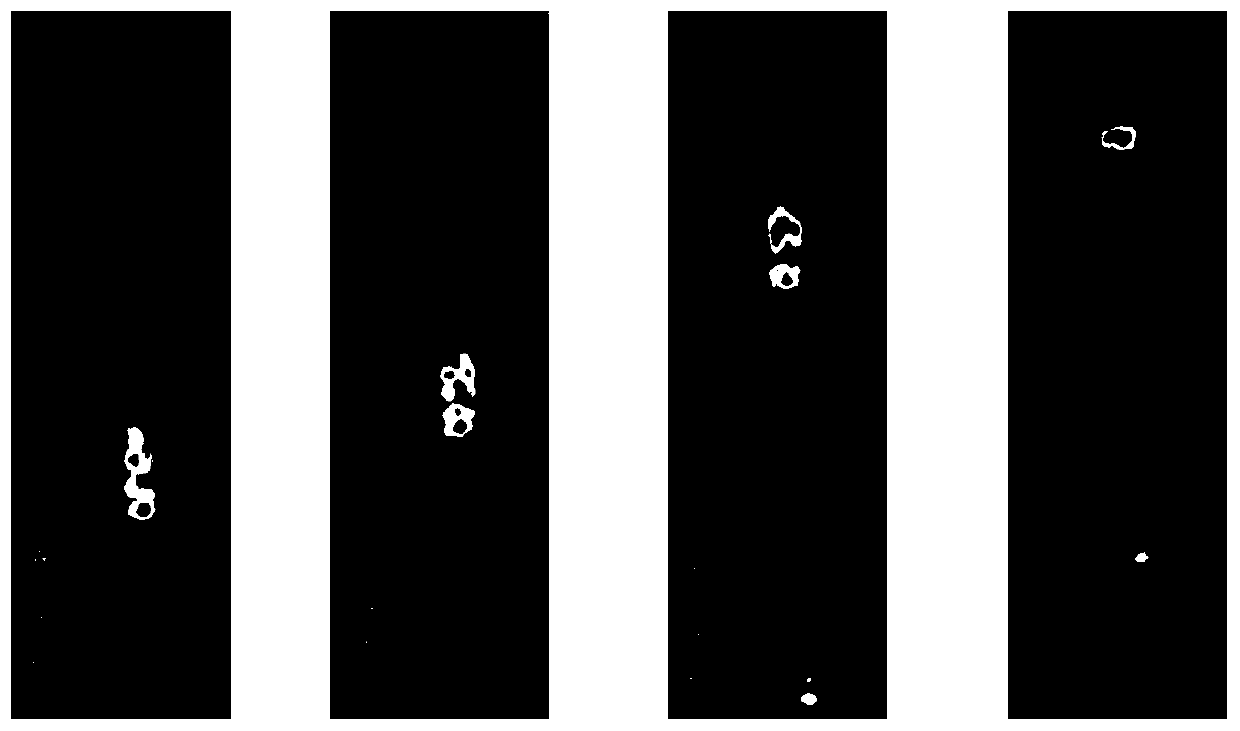

[0039] Embodiment three: as Figure 3-5 As shown, the preparation method and application of a kind of floating and swimming micromachine involved in this embodiment, the time series photos of the photoacoustic imaging motion of the floating and swimming micromachine obtained in this test example are as follows image 3 shown, from image 3 It can be seen that this floating micromachine can move upwards in water driven by air bubbles.

[0040] The scanning electron micrograph of the floating micromachine that this test example obtains is as follows: Figure 4 As shown, the diameter of the floating and swimming micromachines is 10-20 μm, and the surface modification of the floating and swimming micromachines has the characteristics of asymmetric distribution.

[0041] The floating and swimming micromachine obtained in this test example is placed in a salt solution to adjust the pH value to realize the movement of the swimming machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com