Additive for battery electrolyte, lithium ion battery electrolyte and lithium ion battery

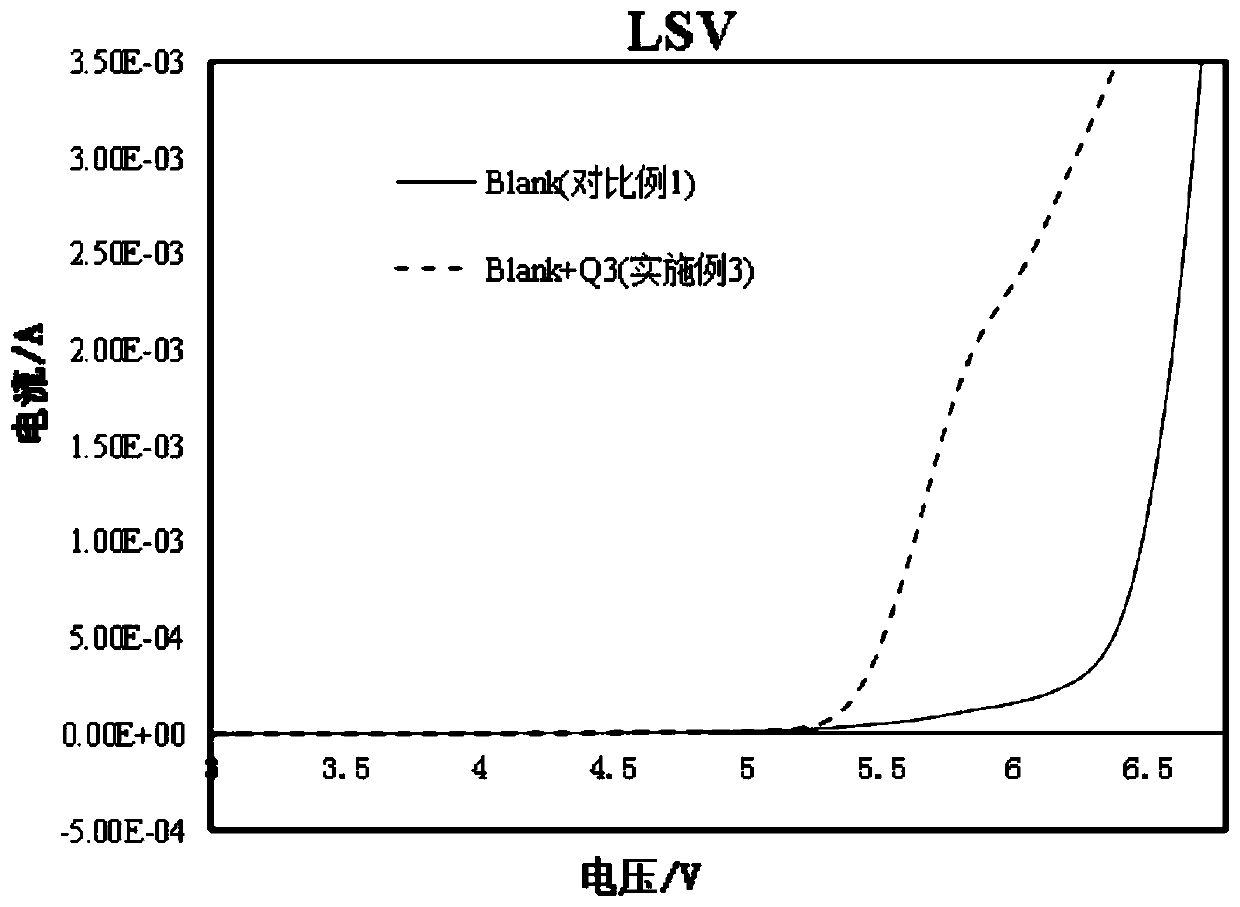

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of high-temperature storage performance and low-temperature discharge performance of the battery, etc., to improve the overall output performance, improve cycle performance and low-temperature discharge performance, and suppress side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A lithium-ion secondary battery comprises a positive pole, a negative pole, a diaphragm and an electrolyte, wherein the positive pole active material is nickel-cobalt lithium manganese oxide (NCM811) material; the negative pole active material is a silicon-carbon composite material (Si / C), and the The preparation method of lithium ion secondary battery comprises the following steps:

[0079] Mix the positive electrode active material NCM811, conductive carbon black and binder polyvinylidene fluoride according to the mass ratio of 96.8:2.0:1.2, and disperse them in N-methyl-2-pyrrolidone to obtain the positive electrode slurry, and make the positive electrode slurry uniform Coated on both sides of the aluminum foil, after drying, calendering and vacuum drying, and welding the aluminum lead-out wire with an ultrasonic welder to obtain a positive plate (positive plate), the thickness of the plate is between 135 and 155 μm;

[0080] Mix silicon-carbon composite material, co...

Embodiment 2~ Embodiment 14

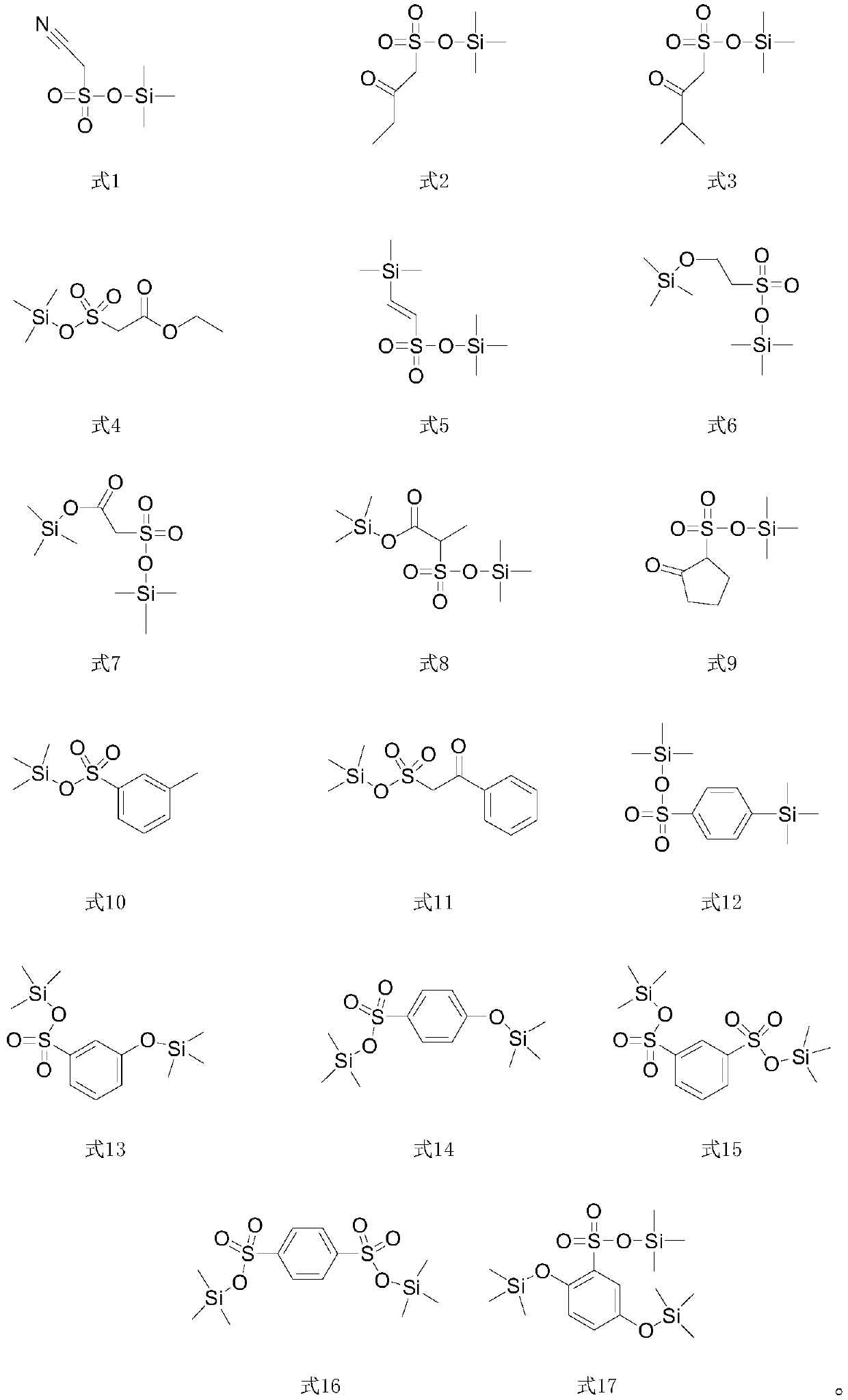

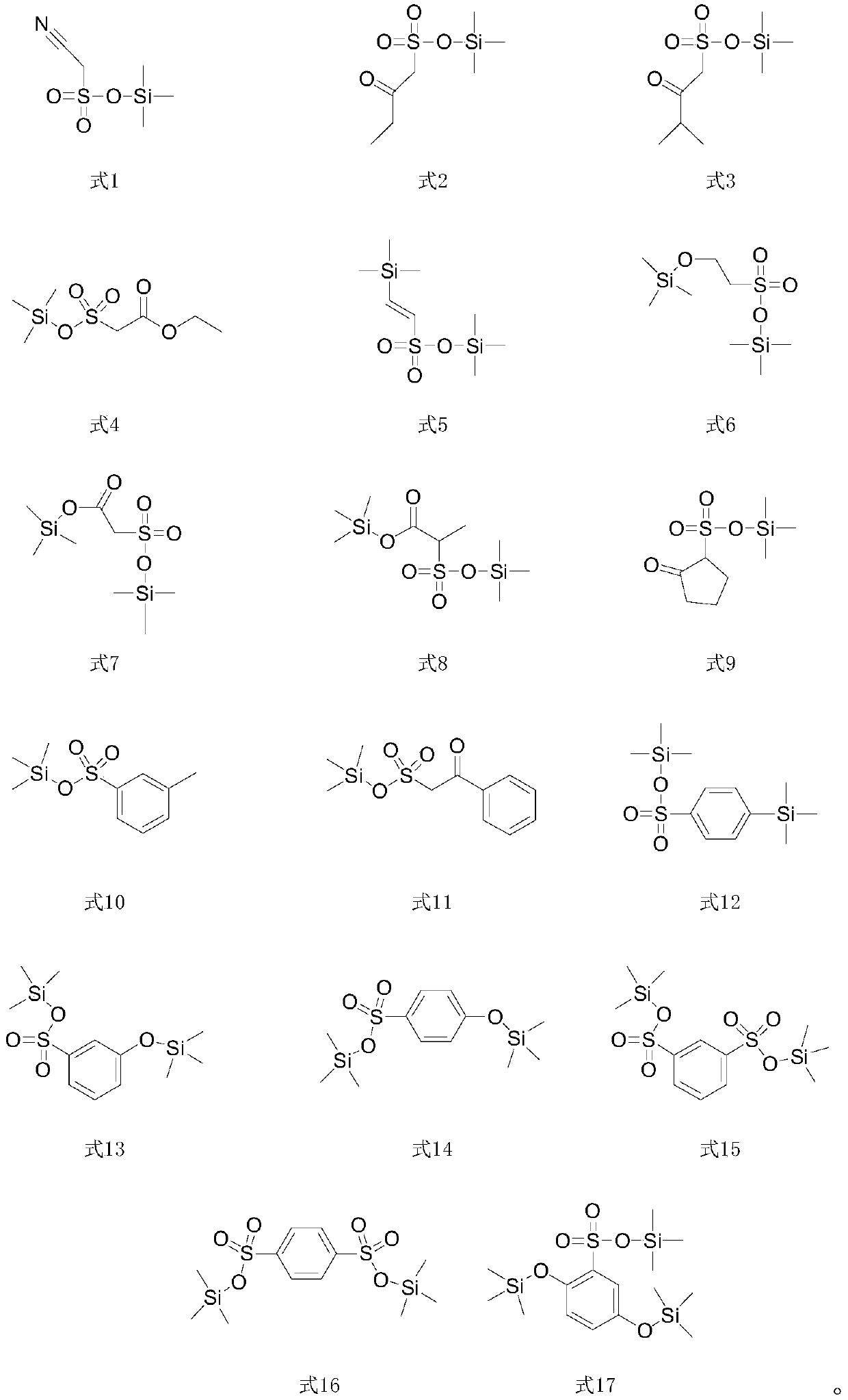

[0085] Examples 2 to 14, except that the components in the electrolyte are different, the preparation of the other positive poles, negative poles, separators, and lithium-ion secondary batteries are the same as in Example 1, and the first type of additives (compounds 1-17 The selection and content of at least one of them are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com