Packaging base material with good thermal expansion performance

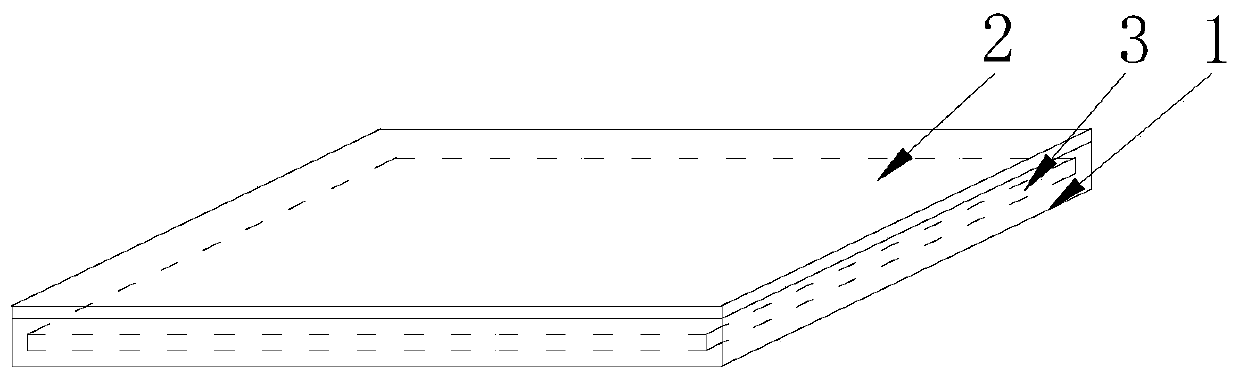

A packaging base and thermal expansion technology, applied to electrical components, circuits, layered products, etc., can solve problems such as poor thermal expansion performance, board warping, and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] S1, 10 parts of fluorinating agent, 10 parts of aluminum foil, 20 parts of silicate, 15 parts of polyester fiber layer, 7 parts of iron oxide, 8 parts of zirconium dioxide, 11 parts of ceramic powder, 12 parts of lithium petalite and 10 parts The raw materials of zinc oxide were put into a high-speed stirring tank and stirred evenly. After stirring for 1 hour, the batch material was prepared. The batch material was heated to 300°C at a heating rate of 3°C / min and pre-fired for 1 hour, so that the decomposable raw materials were fully decomposed. After obtaining the batch material after pre-burning, continue to heat up to 500 ° C at a heating rate of 5 ° C / min, then add 15 parts of lithium carbonate, 20 parts of zinc carbonate, 10 parts of sodium oxide and 12 parts of talcum powder in the batch material, and add 10 parts of deionized water and 10 parts of ethanol, continue stirring for 1h to obtain the mixture;

[0027] S2. Pour the mixture obtained in S1 into a mold w...

Embodiment 2

[0030] S1, 11 parts of fluorinating agent, 11 parts of aluminum foil, 21 parts of silicate, 17 parts of polyester fiber layer, 8 parts of iron oxide, 9 parts of zirconium dioxide, 13 parts of ceramic powder, 14 parts of lithium feldspar and 11 parts Put the raw materials of zinc oxide into the high-speed stirring tank and mix evenly. After stirring for 1.5 hours, the batch material is prepared. The batch material is heated at a heating rate of 8 °C / min to 320 °C for 2 hours, so that the decomposable raw materials are fully decomposed. After obtaining the batch material after pre-burning, continue to heat up to 550 ° C with a heating rate of 10 ° C / min, add 16 parts of lithium carbonate, 21 parts of zinc carbonate, 11 parts of sodium oxide and 13 parts of talcum powder in the batch material, and at the same time Add 15 parts of deionized water and 11 parts of ethanol, and continue stirring for 1.5h to obtain the mixture;

[0031] S2. Pour the mixture obtained in S1 into a mol...

Embodiment 3

[0034] S1, 12 parts of fluorinating agent, 12 parts of aluminum foil, 22 parts of silicate, 18 parts of polyester fiber layer, 9 parts of iron oxide, 10 parts of zirconium dioxide, 15 parts of ceramic powder, 15 parts of lithium feldspar and 12 parts The raw materials of zinc oxide were put into a high-speed stirring tank and stirred evenly. After stirring for 2 hours, the batch material was prepared. The batch material was heated at a heating rate of 10°C / min to 350°C for 3 hours, so that the decomposable raw materials were fully decomposed. After obtaining the batch material after pre-burning, continue to heat up to 600 ° C at a heating rate of 20 ° C / min, and then add 18 parts of lithium carbonate, 22 parts of zinc carbonate, 12 parts of sodium oxide and 15 parts of talcum powder to the batch material, and add 15 parts of deionized water and 12 parts of ethanol, continue to stir to obtain mixture after 2h;

[0035] S2. Pour the mixture obtained in S1 into a mold with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com