Epoxy structural adhesive for assembling prefabricated segments

A technology of epoxy structural adhesives and segments, applied in the field of epoxy adhesives, can solve the problems of operating time, early strength and thixotropy that cannot meet the process requirements at the same time, and achieve mechanical performance requirements, improved stability, and good use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

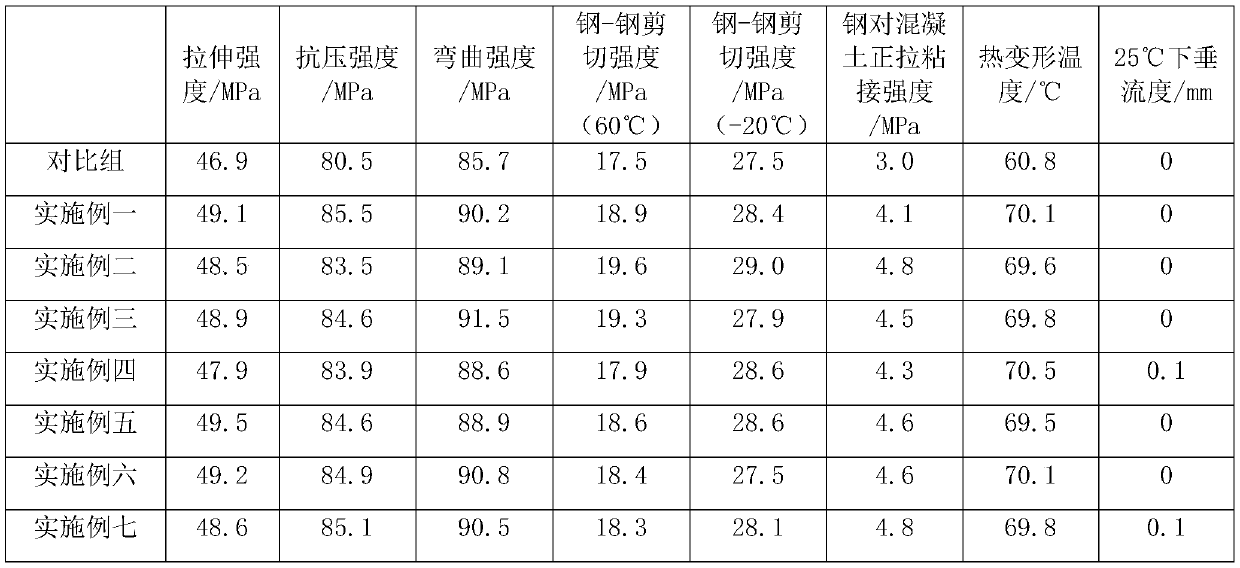

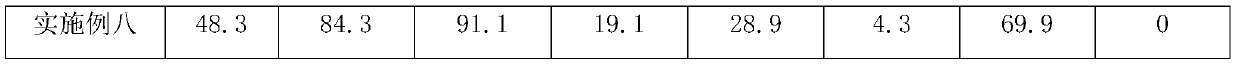

Examples

Embodiment 1

[0033] Epoxy structural adhesive for prefabricated segment assembly: including A component and B component;

[0034] The preparation of A component comprises the following steps:

[0035] S1: Add 40 parts of graphene-modified epoxy resin, 25 parts of bisphenol A epoxy resin, 15 parts of bisphenol F epoxy resin, 5 parts of diluent, and 3 parts of silane coupling agent A into the reactor, and then Stir, during the stirring process, heat the reaction kettle to 60-65°C, and stir at a constant temperature of 60-65°C for 50 minutes, and stir evenly;

[0036] S2: During the stirring process, slowly add 1 part of modified graphene and 1 part of thixotropic agent into the reaction kettle within 5 to 6 minutes, vacuumize the reaction kettle after adding, and stir slowly for 60 minutes;

[0037] S3: Continue to add 20 parts of filler while stirring, and then stir rapidly under vacuum for 60 minutes to obtain component A of Example 1.

[0038] The preparation of component B includes the...

Embodiment 2

[0042] Epoxy structural adhesive for prefabricated segment assembly: including A component and B component;

[0043] The preparation of A component comprises the following steps:

[0044] S1: Add 50 parts of graphene-modified epoxy resin, 30 parts of bisphenol A epoxy resin, 20 parts of bisphenol F epoxy resin, 10 parts of diluent, and 5 parts of silane coupling agent A into the reactor, and then Stir, during the stirring process, heat the reaction kettle to 60-65°C, and stir at a constant temperature of 60-65°C for 50 minutes, and stir evenly;

[0045] S2: During the stirring process, slowly add 2 parts of modified graphene and 2 parts of thixotropic agent into the reaction kettle within 5 to 6 minutes, vacuumize the reaction kettle after adding, and stir slowly for 60 minutes;

[0046] S3: Continue to add 30 parts of filler while stirring, and then stir rapidly under vacuum for 60 minutes to obtain component A of Example 2.

[0047] The preparation of component B includes ...

Embodiment 3

[0051] Epoxy structural adhesive for prefabricated segment assembly: including A component and B component;

[0052] The preparation of A component comprises the following steps:

[0053] S1: Add 45 parts of graphene-modified epoxy resin, 28 parts of bisphenol A epoxy resin, 18 parts of bisphenol F epoxy resin and 8 parts of butanediol diepoxy diluent in sequence. 1. Add 4 parts of epoxy coupling agent into the reaction kettle, and then stir. During the stirring process, the reaction kettle is heated to 60-65°C, and stirred at a constant temperature of 60-65°C for 50 minutes, and stirred evenly;

[0054]S2: During the stirring process, slowly add 1 part of modified graphene and 2 parts of thixotropic agent into the reactor within 5 to 6 minutes. After the addition, vacuumize the reactor and stir slowly for 60 minutes;

[0055] S3: Continue to add 25 parts of silicon dioxide powder while stirring, and then stir rapidly under vacuum for 60 minutes to obtain component A of Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com